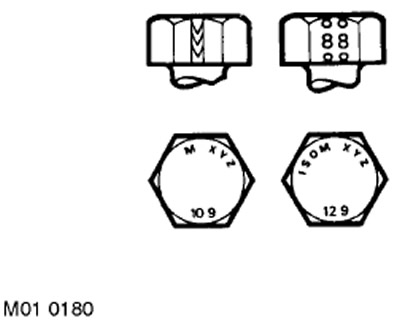

In addition to the manufacturer's designation, the bolt head also has a strength index designation, for example: 8.8; 10.9; 12.9; 14.9. Some bolts have the designation M and the strength index stamped on the edges of the hexagon.

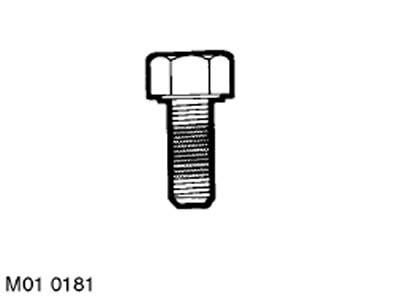

Bolts and screws protected with anaerobic sealant

An anaerobic sealant is applied to the threads of a bolt or screw in a special way prior to assembling the assembly. These bolts can be identified by a colored ribbon that continues 360°around the bolt shaft circumference. The anaerobic sealant is activated during the assembly process of the assembly, then hardens as a result of chemical transformations. This provides a secure fixation of the bolt against loosening.

Unless otherwise noted, anaerobic sealant bolts that are undamaged can be reused. To do this, do the following:

- Clean the bolt body and the threaded hole of anaerobic sealant residues.

- Clean the threads of oil.

- Coat the threads with the recommended sealant.

A bolt with anaerobic sealant can be replaced with a similar bolt, provided that a special anaerobic sealant is used during installation.

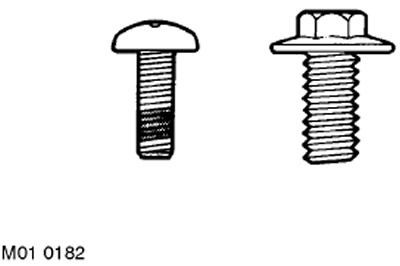

Self-locking bolts and screws

Self-locking screws and bolts (refers to bolts with nylon insert or thread distortion) can be reused, provided that an increase in resistance to screwing is felt when starting to screw in the retaining part of the bolt.

Self-locking bolts or screws have a nylon insert that is installed during the bolt manufacturing process. These bolts can be identified by a colored inset that extends more than 180°on the bolt shank circumference.

Another type of self-locking bolts are bolts with threads that slightly mismatch the threads of the mating hole or nut into which the bolt is threaded.

NOT reuse self-locking bolts to assemble critical connections (engine bearings, flywheel bolts). Always replace a self-locking bolt, screw or nut with a similar part.

NOT install conventional fasteners in place of the designed self-locking nuts, bolts or screws.

Comments on this article