Dismantling

1. Raise the front of the car.

WARNING: Do not work under a vehicle that is only supported by a jack. Always install safety props.

2. Remove the front wheel.

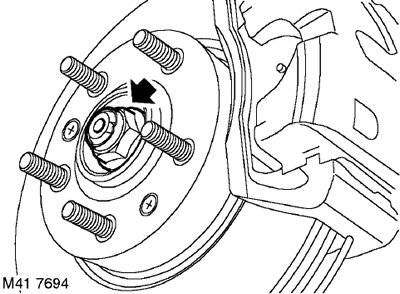

3. Loosen the drive shaft mounting nut.

4. With the help of an assistant depressing the brake pedal, unscrew and discard the nut securing the drive shaft to the hub.

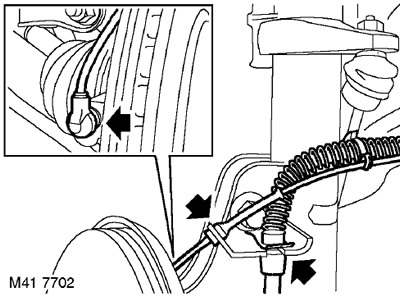

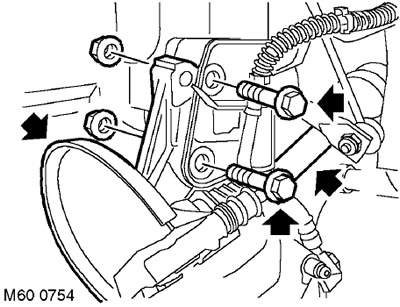

5. Remove a collar of fastening of the right brake hose to an arm. Release the hose from the bracket. Release the electrical cable of the wheel speed sensor and the brake pad wear sensor from the bracket.

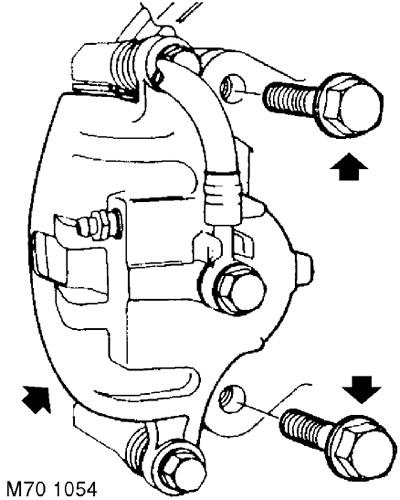

6. Turn away two bolts of fastening of a brake support to a nave. Remove the caliper from the hub and attach to the side.

CAUTION: Do not let the caliper hang on the brake hose.

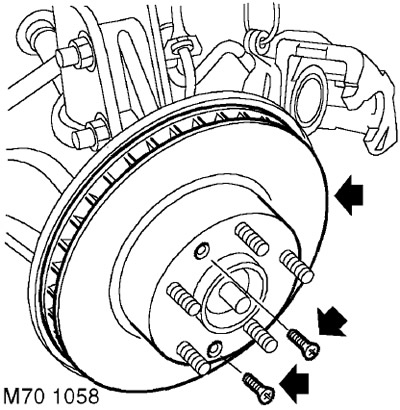

7. Mark the relative position of the brake disc and hub.

8. Turn away 2 screws of fastening of a brake disk and remove a brake disk.

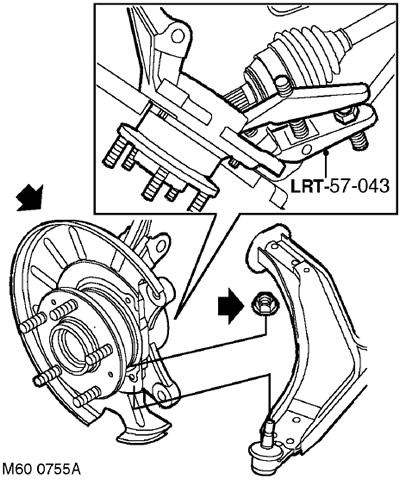

9. Turn away two nuts and remove two bolts of fastening of a nave to a shock-absorber rack of a suspension bracket.

10. Disconnect the hub from the shock absorber.

11. Remove the drive shaft from the hub.

12. While holding the hub from turning, remove the lower arm ball joint nut.

13. Using tool LRT-57-043, disconnect the ball pin.

14. Remove the hub.

NOTE: If disassembly was carried out only to provide access to other elements of the system, then further disassembly operations should not be performed.

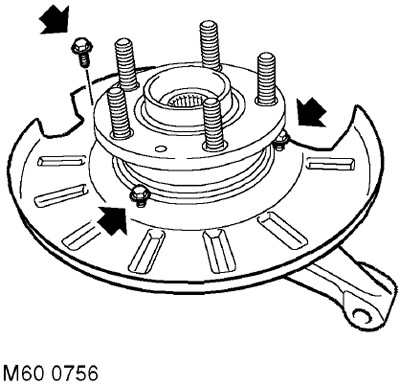

15. Turn away 3 bolts of fastening of a protective casing of a brake disk.

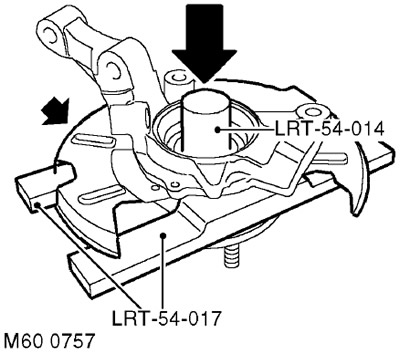

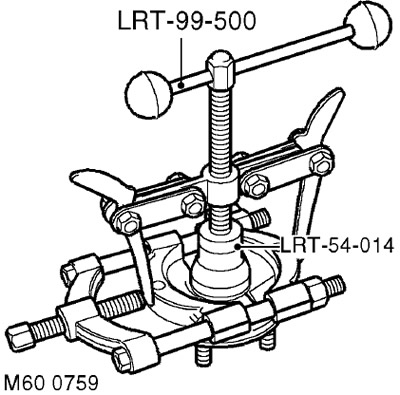

16. Place the hub assembly on the press with tool LRT-54-017 under it. Using tool LRT-54-014, push out the hub flange.

17. Remove a protective casing of a brake disk.

NOTE: This will leave the bearing outer race on the hub flange.

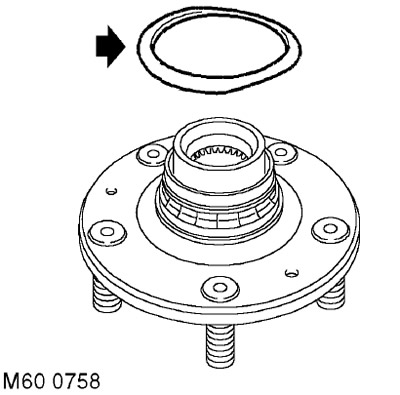

18. Remove the O-ring from the bearing inner race.

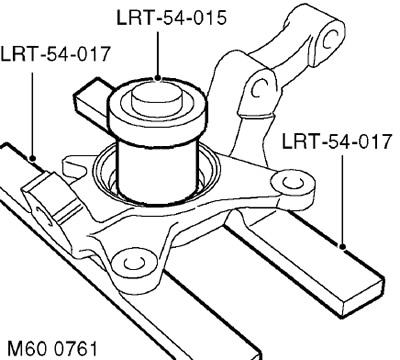

19. Clamp the hub flange in a vise.

20. Clamp the bearing inner race with both clamps of an appropriate bearing puller so that the inner surfaces of the clamps fit into the groove in the inner race.

For 2002 and later vehicles, there is no groove on the inner race of the bearing. To remove the inner race, wrap the bearing puller around the surface of the inner race.

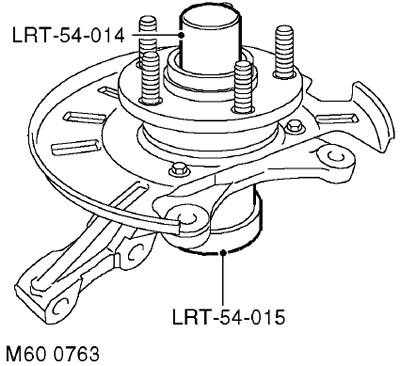

21. Using tool LRT-99-500 and mandrel LRT-54-014, remove the bearing inner race from the hub flange.

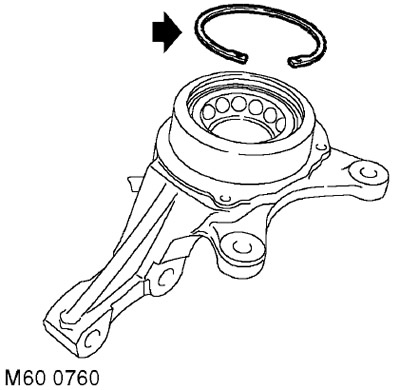

22. Remove the circlip from the bearing.

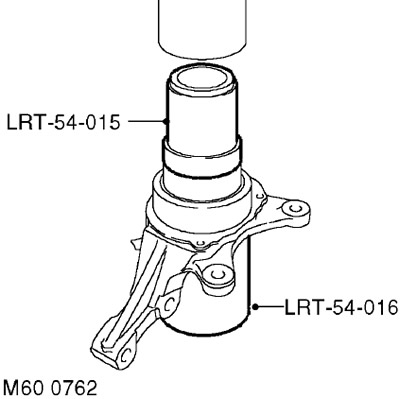

23. Place the hub on a press and use tools LRT-54-015 and LRT-54-017 to remove the bearing and discard it.

CAUTION: Never reuse a bearing.

Installation

1. Clean the hub and its flange of dirt.

2. Place tool LRT-54-016 under the hub and use tool LRT-54-015 to press in the new bearing.

WARNING: One side of the bearing is magnetized. The magnetic side of the bearing can be identified by the matt black surface. The bearing must be installed with the magnetic side facing the inside of the vehicle. Before installing a bearing, make sure that the magnetic side of the bearing is clean. The bearing must be handled with extreme care.

3. Establish on a nave a lock ring.

4. Establish a protective casing of a brake disk, establish bolts of its fastening and tighten them with the moment of 8,5 Nm.

5. Place tool LRT-54-015 under the bearing and press the hub flange into it using tool LRT-54-014.

6. Clean the drive shaft.

7. Install the hub assembly on the lower arm. Install a new nut and tighten it to 65 Nm.

8. Insert the drive shaft into the hub.

9. Align the hub with the shock absorber strut, install the bolts with nuts and tighten the nuts to a torque of 205 Nm.

10. Clean the mating surfaces of the brake disc and hub flange.

11. Aligning the marks, install the brake disc on the hub flange. Install the screws and tighten them with a torque of 5 Nm.

12. Clean the mating surfaces of the brake caliper and hub.

13. Position the caliper on the brake disc, install the bolts and tighten them with a torque of 100 Nm.

14. Fix a brake hose on an arm and establish a collar.

15. Clean the surface of the wheel speed sensor, apply an anti-stick lubricant, and install it on the hub.

CAUTION: Make sure that the wheel speed sensor is fully inserted into the hub, i.e. touching the ring gear.

16. Attach the sensor cable to the bracket.

17. Install a new drive shaft nut and tighten it to 400 Nm. Lock the nut on the end of the drive shaft.

18. Lock the nut.

19. Replace the wheel (wheels) and tighten the nuts to a torque of 115 Nm.

20. Remove props and lower the car.

Comments on this article