Dismantling

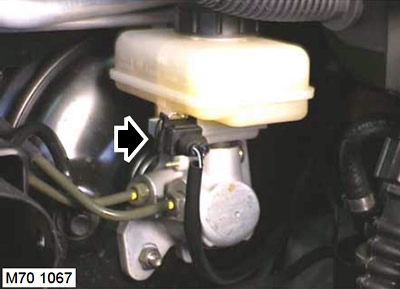

1. Disconnect the multi-contact electrical connector of the emergency brake fluid level sensor.

2. Place a cloth under the brake master cylinder to avoid splashing brake fluid.

CAUTION: Brake fluid can damage paintwork. If brake fluid comes into contact with painted surfaces, remove any traces of fluid immediately and wash the area with water.

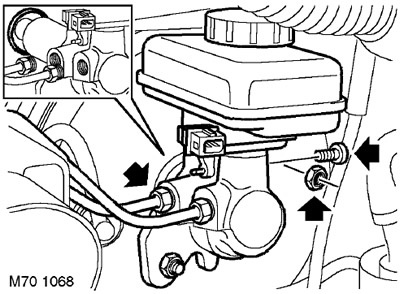

3. Disconnect the clutch of the pipeline of the auxiliary brake circuit from the master cylinder.

4. Disconnect the clutch of the pipeline of the main brake circuit from the master cylinder.

CAUTION: Always plug fittings and openings to keep dirt out of the system.

5. Remove the Torx bolt securing the master cylinder reservoir to provide access to the master cylinder nut.

6. Turn away and remove two nuts of fastening of the main brake cylinder to the vacuum amplifier and remove the main cylinder.

7. Screw a bolt with a Torx head to a reservoir of the main brake cylinder.

8. Remove and discard O-ring.

Installation

1. Clear adjoining surfaces of the main brake cylinder and the vacuum amplifier.

2. Turn away a bolt with a Torx head by means of which the reservoir fastens to the main brake cylinder.

3. Establish a new sealing ring on the main brake cylinder.

4. Align the pusher rod with the master brake cylinder and install the cylinder on the vacuum booster.

5. Install new nuts and tighten them to 25 Nm.

6. Install the Torx head bolt that secures the reservoir to the brake master cylinder. Tighten the bolt with a torque of 8 Nm.

7. Clear places of accession of brake pipelines and tips of pipelines.

8. Connect the pipelines of the main and auxiliary circuits and tighten the couplings with a torque of 17 Nm.

9. Connect a multicontact electric socket of the gauge of emergency level of a brake liquid.

10. Remove air from the brake system.

BRAKING SYSTEM, ADJUSTMENTS, Bleeding of air from the brake system.

Comments on this article