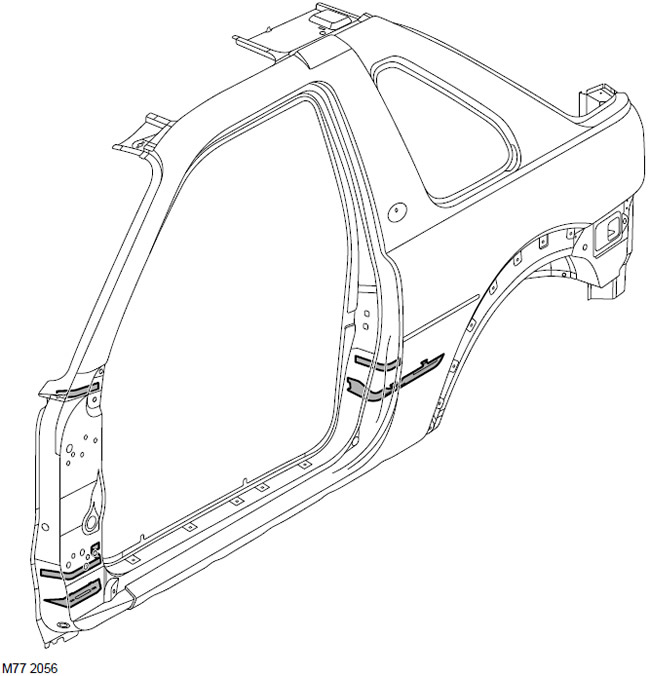

The picture shows the 3-door version of the body.

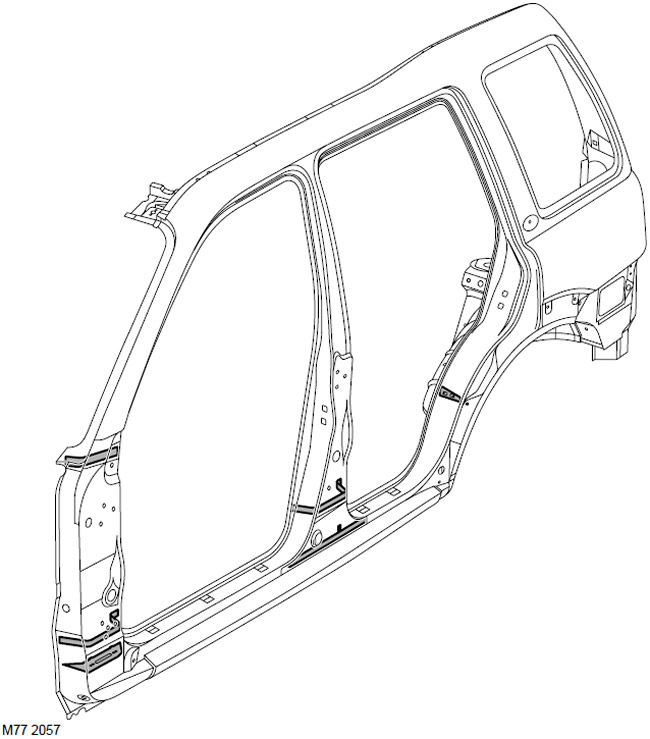

The figure shows the 5-door version of the body.

Expandable foam seals are used in various body cavities to improve vehicle performance. These seals expand during the painting process during assembly of the car and tightly fill the cavity space. Seals are used in various places of the car.

The main task of these seals is to isolate the car's salt from noise and vibration, especially from road noise. Soundproof seals are placed so that they make it difficult to amplify the sound in this structural element and contribute to the reflection of sound waves from road and aerodynamic noise from the car body.

Another function of acoustic seals is to seal closed cavities from water, air, dust and gases.

Another advantage of using foam materials inside cavities is a significant increase in the rigidity and strength of the body elements, which improve safety in the event of a collision.

Foaming seals are based on Betacore 4300 expandable synthetic rubber.

All foaming sealants are applied to the body unpainted in metal, and in the process of heating after painting, they expand, increasing in volume up to eight times.

Replacing seals

Since the heating temperature of parts during painting during repair operations is much lower than during factory painting, a different technology is required when replacing seals during repair. When replacing soundproofing materials, the following procedure must be followed.

If a repair is replacing a foamed part, the cavities of the new part must also be filled with sound-absorbing filler. Acoustic filler should be applied after painting and protective wax has been applied to the internal surfaces of the cavities.

The available cavities to be filled with acoustic filler are shown in the following figures. When applying a foaming material, it must fill the entire space of the cavity.

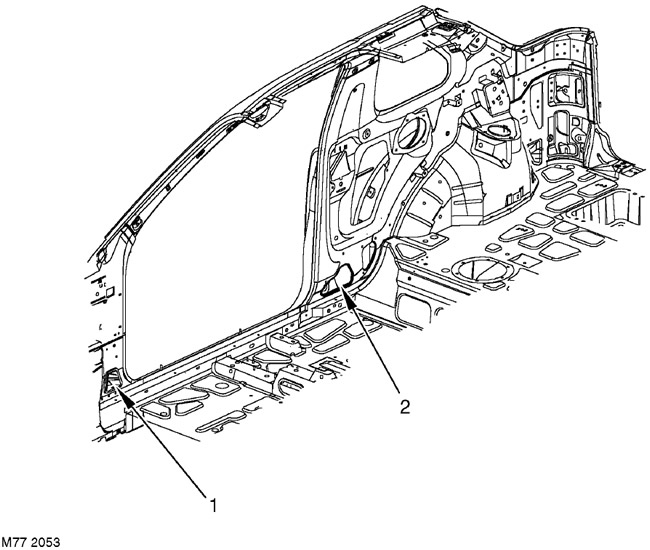

Injection points for foaming sound absorbing material - 3-door version

Joints of parts located symmetrically as shown in the figure are also subject to processing.

- 1 - Rack amplifier panel joints "A" with inner sill reinforcement

- 2 - Rack amplifier panel joints "B" with inner sill reinforcement

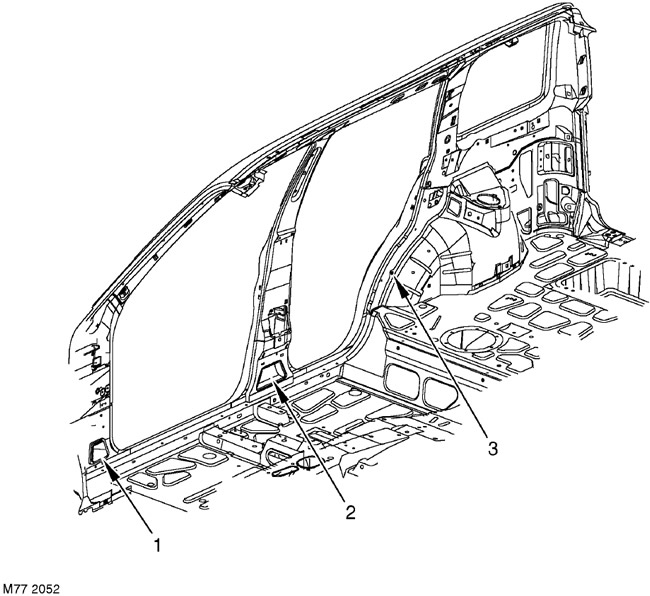

Injection points for foaming sound absorbing material - 5-door version

Joints of parts located symmetrically as shown in the figure are also subject to processing.

- 1 - Rack amplifier panel joints "A" with inner sill reinforcement

- 2 - Rack amplifier panel joints "B/C" with inner sill reinforcement

- 3 - Joints of the outer panel of the wheel arch with the outer panel of the sidewall of the body

Comments on this article