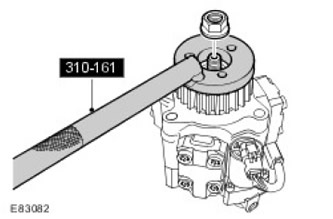

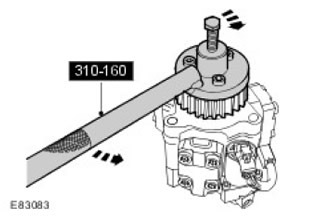

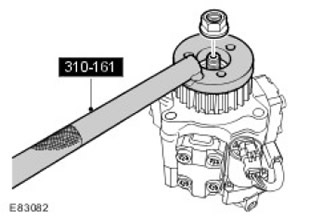

Special tool

Holding fixture 310-161 Holding fixture 310-161 |  Puller 310-160 Puller 310-160 |

Removing

WARNING: Do not carry or use a cell phone while working on or near any fuel related items. There is a danger of ignition of flammable vapours. Failure to follow these instructions may result in personal injury.

CAUTION: Do not perform any fuel system repairs while the engine is running. The fuel pressure in the system can reach 1650 bar. Failure to follow this instruction may result in personal injury.

WARNING: Do not smoke and avoid lit cigarettes and open flames of any kind when working on or near fuel-related items There is a risk of ignition of flammable vapors. Failure to follow these instructions may result in personal injury.

CAUTION: When carrying out subsequent work, care must be taken in handling fuel. Always be aware of the possibility of fuel splashing and observe fuel handling precautions. Failure to follow these instructions may result in personal injury.

ATTENTION: Make sure that the workshop area where the vehicle is being serviced is as clean and dust free as possible. Dirt and dust from working on the clutch, brakes, or from machining or welding can contaminate the fuel system and lead to malfunctions later.

CAUTION: Always perform the cleaning procedure before making any repairs to the fuel injection system components. Failure to follow this instruction may lead to the penetration of dirt into the fuel injection system.

WARNING: Diesel fuel injection equipment is manufactured to very precise tolerances and with very close clearances. Therefore, it is especially important to observe absolute cleanliness when working with these elements. Be sure to insert plugs into any open holes or lines. Failure to follow this instruction may lead to the penetration of dirt into the fuel injection system.

WARNING: Do not disassemble or clean the inside of the fuel pump, even with ultrasonication. Always install a new fuel pump if necessary.

1. Disconnect the battery ground wire. For more information refer to Specification.

2. Remove the crankcase ventilation oil separator.

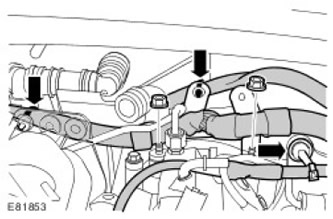

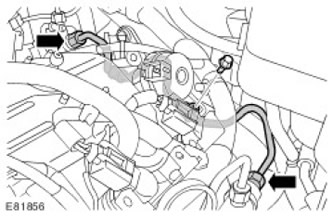

3. Release the fuel supply harness.

- Release 3 clips.

- Loosen 2 nuts.

4. Remove the fuel pump belt cover.

- Move the engine wiring harness to access the fuel pump belt cover.

- Release 3 clips.

5.

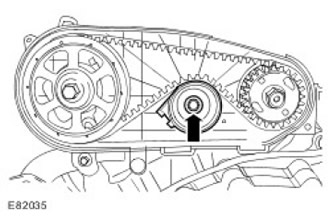

NOTE: The fuel pump belt is out of sync with the engine.

Remove and discard the fuel pump belt tensioner. Remove the high pressure fuel pump drive belt tensioner bolt and discard it.

6.

NOTE: The fuel pump rotates counterclockwise when viewed from the rear of the engine.

Remove and discard the fuel pump belt.

7.

NOTE: Left side shown, right side done in the same way.

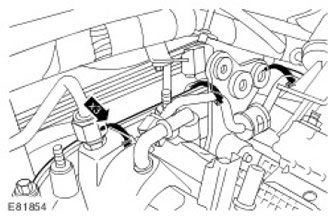

Remove the noise insulation of the fuel injectors. Remove 4 clips.

NOTE: The right high pressure fuel feed line was already removed when the crankcase breather oil separator was removed.

8. Release the left high pressure fuel supply line. Turn out a bolt.

9.

CAUTION: Ensure that the high pressure fuel supply line remains in contact with the fuel pump and fuel supply manifold until both connections are disconnected and cleaned. Failure to follow this instruction may lead to the penetration of dirt into the fuel injection system.

Remove left high pressure fuel feed lines and discard. Insert plugs into open holes.

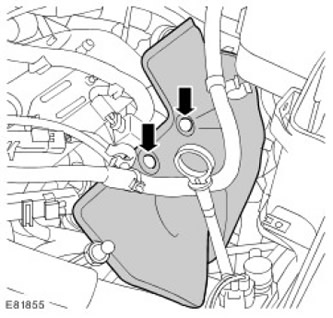

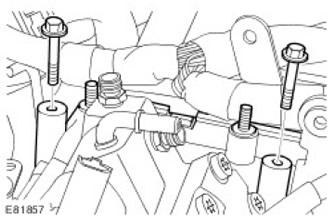

10. Remove the timing belt rear roof inspection panel. Turn out 2 bolts.

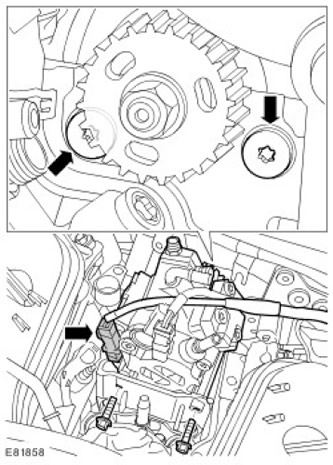

11. Remove the high pressure fuel pump.

- Remove and discard 2 Togh bolts.

- Loosen and discard 2 bolts.

- Release the electrical connector.

12.

NOTE: Do not proceed with disassembly if the element is being removed only to gain access.

Using the special tool, loosen the high pressure fuel pump pulley nut.

13. Using the special tool, remove the high pressure fuel pump pulley.

Installation

1. Using the special tool, install the high pressure fuel pump pulley.

- Clean the mating surfaces of the elements.

- Tighten the nut to 50 Nm.

2. Install the high pressure fuel pump.

- Clean the mating surfaces of the elements.

- Screw, without tightening, new bolts.

- Stage 1: Tighten the Tox bolts to 23 Nm.

- Stage 2: Tighten the M8 bolts to 23 Nm.

- Connect the electrical connector.

3. Install the timing belt rear roof inspection panel. Tighten the bolts to 10 Nm.

4. CAUTION: Make sure the fuel pump belt tensioner tail is correctly positioned in relation to the fuel pump belt rear cover. Failure to follow these instructions may result in engine damage.

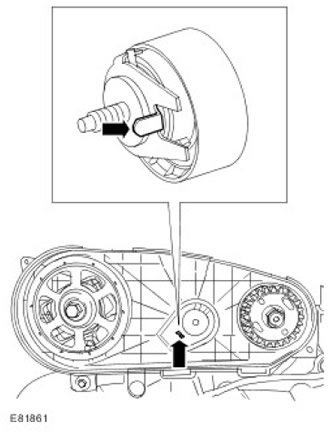

NOTE: Do not remove the fuel pump belt tensioner lock pin at this point.

Install a new fuel pump belt tensioner.

- Clean the mating surfaces of the elements.

- Insert the shank of the new fuel pump belt tensioner into the rear fuel pump belt cover.

- Tighten the bolt to 25 Nm.

5.

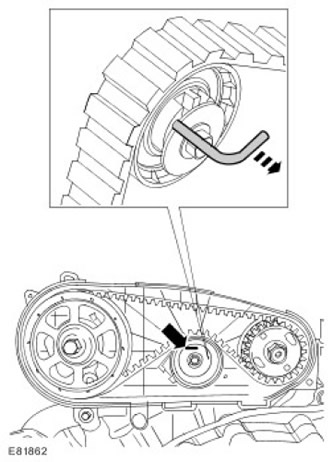

CAUTION: Do not install a new fuel pump belt on the pulleys with the fuel pump belt tensioner lock pin removed. Failure to follow this instruction may result in damage to the fuel pump belt.

NOTE: The fuel pump rotates counterclockwise when viewed from the rear of the engine.

Install a new fuel pump belt. Make sure the parts are clean and dry.

6. Remove and discard the fuel pump belt tensioner lock pin.

7. Install the fuel pump belt cover.

- Secure with 3 clips.

- Move the engine wiring harness to access the fuel pump belt cover.

- Secure with 3 clips.

- Tighten the nuts to 10 Nm.

- Remove plugs from open connections.

- Clean the mating surfaces of the elements.

- Install new high pressure fuel feed lines, but do not permanently fix.

- Step 1: Tighten the high pressure fuel supply pipe nipple on the fuel rail to 15 Nm.

- Step 2: Tighten the high pressure fuel feed line nipple on the fuel pump to 15 Nm.

- Stage 3: Tighten the high pressure fuel supply pipe nipple on the fuel rail to 30 Nm.

- Stage 4: Tighten the nipple connection of the high pressure fuel supply line on the fuel pump to 30 Nm.

- Check the position of the clamp.

- Tighten the bolt to 10 Nm.

12. Install the crankcase ventilation oil separator.

13. Connect a wire of weight of the accumulator. For more information refer to Specification.

14. Remove air from the fuel supply system. For more information, refer to Bleeding the Low Pressure Fuel System (19.50.07)

Comments on this article