Removing

WARNING: Wait at least 30 seconds after stopping the engine before attempting any repair to the high pressure fuel injection system. Failure to follow this instruction may result in injury.

WARNING: Do not smoke or allow a lit cigarette or open flame of any kind to be present when working on or near fuel related items. There is a danger of ignition of flammable vapours. Failure to follow these instructions may result in personal injury.

CAUTION: When carrying out subsequent work, care must be taken in handling fuel. Always be aware of the possibility of fuel splashing and observe fuel safety precautions. Failure to follow these instructions may result in personal injury.

CAUTION: Do not perform any fuel system repairs while the engine is running. The fuel pressure in the system can reach 1650 bar. Failure to follow this instruction may result in injury.

WARNING: Make sure that the workshop area where the vehicle is being worked on is as clean and dust free as possible. Dirt and dust from working on the clutch, brakes, or from machining or welding operations can contaminate the fuel system and cause performance problems.

CAUTION: Always perform the cleaning procedure before making any repairs to the fuel injection system components. Failure to do so may result in contaminants entering the fuel injection system.

WARNING: Diesel fuel injection equipment is manufactured to very precise tolerances and very close clearances. Therefore, when working with these elements, it is especially important to observe absolute cleanliness. Be sure to insert plugs into any open holes or lines. Failure to do so may result in contaminants entering the fuel injection system.

CAUTION: Do not remove the FRP sensor from the fuel rail.

NOTE: Fuel rail and fuel rail pressure sensor (FRP) only shipped as a single unit. Do not remove the FRP sensor from the fuel rail. If a new FRP sensor is required, a new fuel rail assembly must be installed.

1. Disconnect a wire of weight from the storage battery. For more information refer to Specification.

2. Remove the engine cover. For more information refer to Engine Cover - 2.7L Diesel (12.30.50)

3. Disconnect the low pressure fuel lines. Insert plugs into open holes.

4. Disconnect both hoses from the bypass pipe of the exhaust gas recirculation system (EGR) for coolant. Clamp the EGR coolant hoses to minimize coolant loss.

5. Remove the EGR coolant overflow pipe. Turn out 2 bolts of fastening.

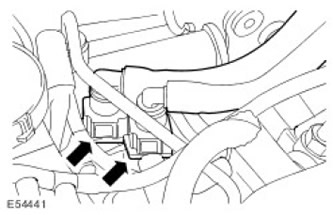

6.

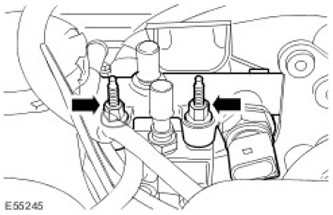

NOTE: Left side shown, right side works in the same way.

Release the right and left high pressure fuel supply lines. Turn out a bolt.

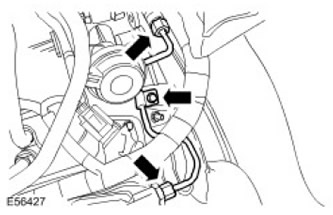

7.

CAUTION: Ensure that the high pressure fuel supply line remains in contact with the fuel rail and fuel rail until both connections are disconnected and cleaned. Failure to do so may result in contaminants entering the fuel injection system.

NOTE: Left side shown, right side works in the same way.

Remove and discard the right and left high pressure fuel feed lines. Insert plugs into open holes.

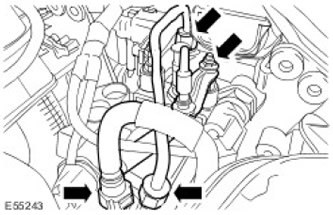

8.

CAUTION: Make sure the high pressure fuel supply line remains in contact with the fuel pump and fuel rail until both connections are disconnected and cleaned. Failure to do so may result in contaminants entering the fuel injection system.

NOTE: The crankcase breather oil separator is shown removed for clarity.

Remove the high pressure fuel supply line and discard it. Insert plugs into open holes.

9. Release the low pressure fuel line.

- Disconnect the low pressure fuel line.

- Insert plugs into open holes.

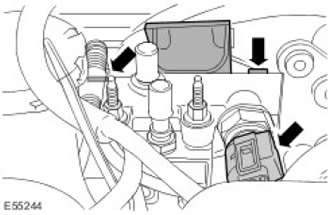

10. Disconnect the fuel rail pressure sensor electrical connector (FRP). Release the fuel supply wiring harness.

11. Remove the fuel rail assembly. Remove 2 pins.

Installation

CAUTION: Do not remove the FRP sensor from the fuel rail.

NOTE: The fuel rail and FRP sensor are only shipped as a single unit. Do not remove the FRP sensor from the fuel rail. If a new FRP sensor is required, a new fuel rail assembly must be installed.

1. Install the FRP sensor and fuel rail assembly. Install the fuel rail mounting studs, but do not fully tighten them at this stage.

2. Connect the electrical connector of the FRP sensor. Connect the fuel supply harness.

3. Install a new high pressure fuel supply line.

- Remove plugs from open connections.

- Install the new high pressure fuel feed line, but do not tighten the connections yet.

- Tighten the fuel rail mounting studs to 23 Nm.

- Stage 1: Tighten the high pressure fuel supply pipe fitting on the fuel pump side ' (tightening torque 15 Nm).

- Stage 2: Tighten the high pressure fuel supply pipe fitting on the fuel distribution rail to 15 Nm.

- Stage 3: Tighten the high pressure fuel supply pipe fitting on the fuel pump side ' (tightening torque 30 Nm).

- Stage 4: Tighten the high pressure fuel supply pipe fitting on the fuel distribution rail to 30 Nm.

- Remove plugs from open connections.

- Connect the low pressure fuel line.

- Remove plugs from open connections.

- Install new high pressure fuel feed lines, but do not permanently fasten them.

- Stage 1: Tighten the high pressure fuel supply pipe fitting on the fuel rail to 15 Nm.

- Stage 2: Tighten the high pressure fuel supply pipe fitting on the fuel distribution rail to 15 Nm.

- Stage 3: Tighten the high pressure fuel supply pipe fitting on the fuel rail to 30 Nm.

- Stage 4: Tighten the high pressure fuel supply pipe fitting on the fuel distribution rail to 30 Nm.

7. Install the EGR coolant overflow pipe.

- Screw in 2 bolts of fastening of a bypass pipe of system EGR for a cooling liquid.

- Tighten to 13 Nm.

9. Connect low pressure fuel lines. Remove plugs from open connections.

10. Install the engine cover. For more information refer to Engine Cover - 2.7L Diesel (12.30.50)

11. Connect a wire of weight to the storage battery. For more information refer to Specification.

12. Remove air from the fuel supply system. For more information, refer to Bleeding the Low Pressure Fuel System (19.50.07)

13. Check the coolant level and top up if necessary.

Comments on this article