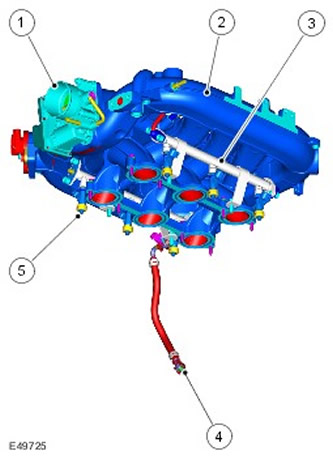

Location of components

| Item name | Spare part number | Description |

| 1 | - | throttle body |

| 2 | - | Intake manifold |

| 3 | - | fuel rail |

| 4 | - | Fuel supply pipe |

| 5 | - | fuel injectors (6 pcs.) |

General information

The main components of the fuel injection system are the intake manifold, fuel pump, fuel rail and six injectors. The fuel pump delivers fuel at constant pressure from the tank to the fuel rail through a tube running under the floor of the body. The fuel rail distributes fuel evenly across all six injectors.

Intake manifold

The intake manifold is located at the top of the engine. The collector is made of composite material with metal inserts for fastening. The manifold consists of a central receiver, from which separate inlet pipes go to each cylinder. For more information, please refer to Intake Air Distribution and Filtering (303-12A)

Fuel pump

A submersible electric fuel pump and a fuel pressure regulator are installed in the tank. The pump module flange on the top of the tank allows access to the fuel pump for removal and installation.

During operation, the fuel pump maintains a constant fuel pressure in the fuel rail. The pressure regulator controls the pressure. Excess fuel from the pressure regulator is fed to the forward transfer pump. Pressure control ensures that fuel is supplied to the fuel rail in excess of the maximum requirements of the engine; therefore, a constant pressure in the fuel rail is maintained regardless of operating conditions. For more information refer to Fuel Tanks and Lines (310-01A)

The fuel pump is controlled by the ECM through the fuel pump relay located in the battery junction box (BJB).

When the ignition is set to position II, the ECM provides a ground connection for the fuel pump relay coil at terminal 95 of the C0634 ECM connector. The relay turns on briefly to create pressure in the fuel system. When the ECM is signaled by the crankshaft speed sensor (CKP) detects that the engine is cranking, the ECM keeps the fuel pump relay energized for as long as the engine is running. For more information refer to Electronic Engine Controls (303-14A)

Throttle body

The throttle body is located in front of the intake manifold and centered on it. The electronic throttle controls the engine torque. The electronic pedal assembly senses the throttle position. The signal from the pedal assembly is sent to the EMS and the throttle is opened to the desired angle by the motor built into the throttle body. Sensors installed in the throttle body determine the position of the damper and the rate of change of its position. For more information refer to Electronic Engine Controls (303-14A)

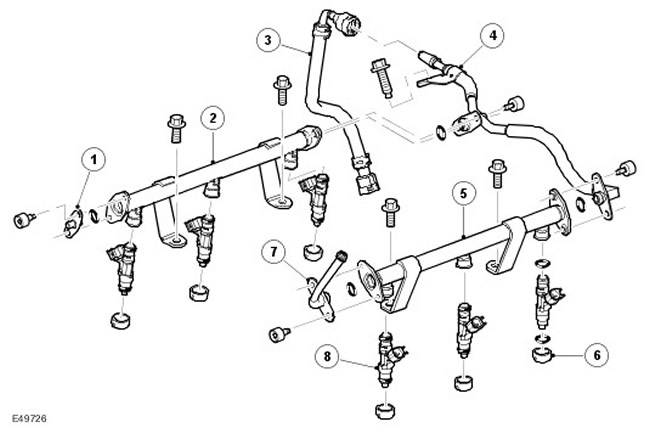

Fuel rail

| Item name | Spare part number | Description |

| 1 | - | end cap |

| 2 | - | Right fuel rail |

| 3 | - | Fuel supply pipe |

| 4 | - | Fuel supply line |

| 5 | - | Left fuel rail |

| 6 | - | Plug-in nozzle seats |

| 7 | - | Schrader valve |

| 8 | - | nozzles (6 pcs.) |

Each fuel frame maintains a constant fuel pressure of 4.5 bar. The ramps are attached to the cylinder heads with two bolts. Each cylinder head has three fuel injectors connected by a fuel rail. O-rings are used to seal injectors in fuel rails and cylinder heads. A quick coupling connects the fuel supply line from the fuel tank to the fuel rail via a fuel supply pipe.

A flange with two threaded holes on the back of the left and right fuel rails is used to fasten the fuel supply line. The fuel supply line has two ends with metal flanges that are located on the fuel rail. The seal prevents leakage and each flange is secured with two bolts.

The Schrader valve is mounted at the forward end of the left fuel rail. It allows you to check the fuel pressure during service.

Nozzles

Six injectors are installed between the fuel rails and cylinder heads. O-rings are used to seal the connections of the injectors with the fuel rails and cylinder heads, which should be replaced with new ones each time the injector is installed on the engine. To facilitate installation, the O-rings can be lubricated with a small amount of engine oil. Do not use any other type of lubricant. Each nozzle is mounted on a plug-in seat, which must also be replaced with a new one if a nozzle is replaced.

When the power supply to the electromagnetic winding of the nozzle is interrupted, the needle locks the atomizer. Power is supplied to the injector coil through the main relay and the ground circuit is connected through the ECM. The injector is unlocked and locked by applying and disengaging the ECM ground. When the injector is open, fuel is sprayed into the cylinder inlet on the back of the intake valves. The ECM regulates the amount of fuel delivered by the duration of the injector opening. For more information refer to Electronic Engine Controls (303-14A)

Comments on this article