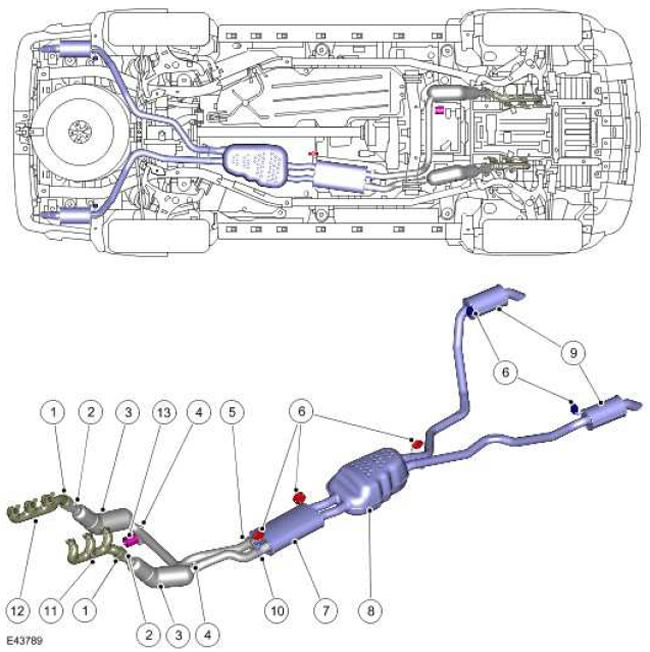

The location of the elements of the exhaust system of the 4.0L V6 engine

| Item name | Spare part number | Description |

| 1 | - | Manifold to Front Section Flange |

| 2 | - | Installation location of the front heated oxygen sensor |

| 3 | - | catalytic converter |

| 4 | - | Installation location of the rear heated oxygen sensor |

| 5 | - | Flange of fastening of the right forward section to back section |

| 6 | - | rubber support (5 pieces.) |

| 7 | - | Front muffler |

| 8 | - | Central muffler |

| 9 | - | Rear silencer |

| 10 | - | Collar of fastening of the left forward section to back section |

| 11 | - | Left collector |

| 12 | - | Right collector |

| 13 | Damper |

General information

The exhaust components of the 4.0L V6 engine are made of stainless steel and are supplied as three separate assemblies.

A catalytic converter is installed in the left and right front sections, and a front muffler is installed in the rear section (except North America), center silencer and two rear silencers.

The system is anchored to the underbody with five rubber mounts that are mounted on mild steel suspension brackets welded to the system. The rubber mounts are mounted on appropriate suspension mounts that are welded to the bottom of the body. Basically, the system is routed along the left side member, then splits in two next to the rear axle differential and exits on both sides of the rear of the body.

Spare parts are supplied to repair the exhaust system. The indentations on the rear section between the center and rear mufflers indicate where to cut off to replace the rear mufflers or the front section. The spare section is attached at the place of cutting by means of a bushing and two clamps.

Front section

Both front sections have a welded flange with two bolt holes to attach to the left and right exhaust manifolds. Flange sealing uses a conical seat in the flange and a cone on the exhaust manifold.

The flange is welded into a short, straight tube, which in turn is welded into the catalytic converter housing. A threaded boss is welded over the hole in the pipe for mounting a front heated oxygen sensor (HO2S).

The catalytic converter outlet in the left front section is a 55 mm diameter pipe with a wall thickness of 1.5 mm welded to the catalytic converter housing. The rear end of the outlet pipe is inserted into the socket of the rear section of the exhaust pipe. A clamp is used to crimp the joint.

The catalytic converter outlet in the right front section is a 55 mm diameter pipe with a wall thickness of 1.5 mm welded to the catalytic converter housing. The back of the pipe under the gearbox is bent to the left, and then again bends and runs parallel to the left pipe. A flange with two holes for studs on the rear section is welded into the rear part of this pipe, to which the pipe is attached with nuts. A metal gasket is used to seal the joint between the flanges of the front and rear sections.

Threaded lugs are welded above the holes in the outlet pipes of the right and left converters for installing rear heated oxygen sensors (HO2S).

Rear section

The rear section has a short 55mm diameter, 1.5mm wall thickness flared 55mm ID spigot into which the left front section is inserted. The pipe is welded to the front muffler housing assembly. The second short spigot, 55 mm in diameter, with a wall thickness of 1.5 mm, has a welded flange with studs for attaching the flange to the right front section. The pipe is also welded to the front muffler housing assembly.

The front muffler is a single-layer cylinder with two welded end plates and has a volume of 6.4 liters (390.5 in3). Inside the muffler are partitions and perforated pipes that reduce noise when exhaust gases pass through the muffler. A hanging bracket is welded to the front of the muffler for installing a rubber support.

For connection to the center muffler, the front muffler has two short outlet pipes with a diameter of 55 mm and a wall thickness of 1.5 mm.

Central muffler with a volume of 25.2 liters (1538 inches3) consists of two stamped stainless steel shells welded together. Inside the muffler are partitions and perforated pipes that reduce noise when exhaust gases pass through the muffler. A hanging bracket is welded to the right front of the muffler for installing a rubber support.

The muffler has two outlet pipes with a diameter of 55 mm and a wall thickness of 1.5 mm, bent to bend around the elements of the rear suspension.

Each of the outlet pipes is welded to the rear mufflers. The outlet pipes have hanging brackets for installing rubber supports.

A hanging bracket is welded to the front of each rear muffler for mounting a rubber support. The muffler is a circular cylinder with a tubular baffle lined with fiberglass to increase the efficiency of sound absorption. The volume of each muffler is 2.7 liters (165"3).

Each muffler has an outlet pipe with a diameter of 55 mm and a wall thickness of 1.2 mm. Each outlet is folded down to direct exhaust gases away from the rear of the vehicle.

Catalytic converter

The engine management system provides accurate fuel metering to the combustion chambers, which ensures the most efficient use of fuel and reduces the emission of toxic substances.

To further reduce the content of carbon monoxide and hydrocarbons in the exhaust gases, a catalytic converter is integrated into the front exhaust pipe. In the catalytic converter, the exhaust gases pass through honeycomb ceramic elements with a special surface treatment ("washcoat"). Layer "washcoat" increases the surface area of the walls of ceramic elements by about 7000 times. per layer "washcoat" a coating is applied that contains metals that are active ingredients for converting toxic substances into inert ones. These metals oxidize the carbon monoxides and hydrocarbons in the exhaust gases and thus convert them to carbon dioxide and water, respectively.

Comments on this article