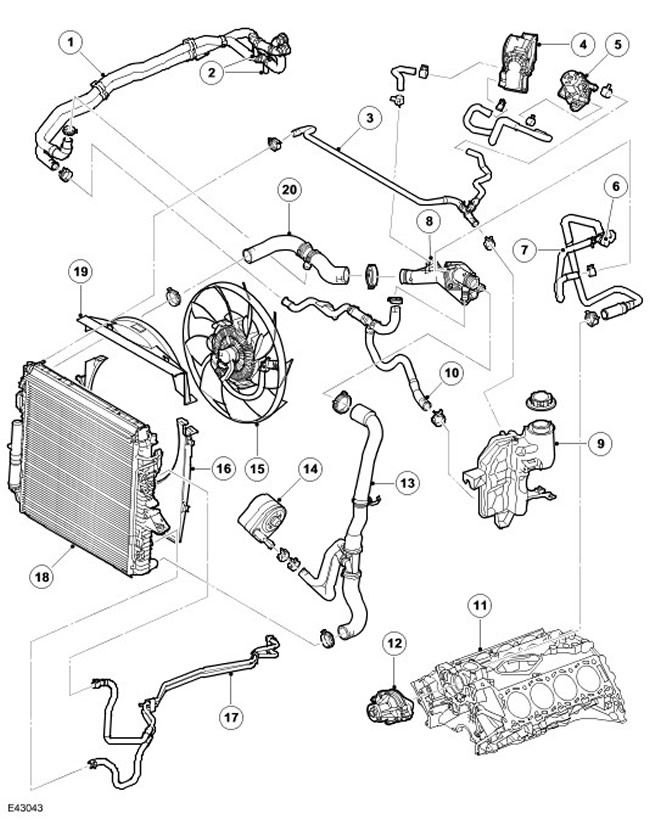

| Item name | Spare part number | Description |

| 1 | - | Heater hoses, inlet and outlet |

| 2 | - | Connections for rear heater |

| 3 | - | Hose connecting radiator to expansion tank |

| 4 | - | throttle body |

| 5 | - | EGR valve |

| 6 | - | Air bleed screw |

| 7 | - | Hose connecting the exhaust pipe to the cylinder block |

| 8 | - | Outlet pipe assembly |

| 9 | - | Expansion tank |

| 10 | - | Hose connecting heater to thermostat |

| 11 | - | Cylinder block |

| 12 | - | Water pump |

| 13 | - | Hose connecting radiator to thermostat |

| 14 | - | oil cooler |

| 15 | - | Cooling Fan |

| 16 | - | Bottom casing |

| 17 | - | Transmission Fluid Lines |

| 18 | - | Radiator |

| 19 | - | Top casing |

| 20 | - | Hose connecting the outlet to the radiator |

General information

A bypass-type cooling system is used, which circulates the coolant through the engine and the heater circuit when the main thermostat valve is closed. The main purpose of the engine cooling system is to maintain the optimum temperature of the engine when environmental conditions and engine operation change. Other functions of the cooling system include heating the vehicle interior and cooling the transmission fluid and engine oil.

The cooling system includes the following components:

- Radiator

- Car interior heater core

- coolant pump

- Thermostat

- Expansion tank

- Fan with electro-viscous coupling

- Connecting hoses and pipelines

Engine cooling system

The coolant circulates through the system under the action of a centrifugal type pump installed in front of the engine and driven by an additional V-ribbed belt. The pump pumps coolant through the cylinder block and cylinder heads through a chamber located in the collapse of the cylinder block. After passing through the engine, the working fluid returns to the thermostat housing. The fluid then flows through the top hose to the interior heater tube. The heater pipes pass through the bulkhead of the engine compartment and return to the engine in the thermostat area.

The engine has a conventional thermostat, which is located so that the temperature of its sensing element is determined by the flow of coolant from both the radiator and the bypass channel. As a result, the opening temperature of the thermostat may vary depending on the environmental conditions. The thermostat housing contains a spring-loaded valve that limits the flow of fluid through the bypass. This means that the engine can temporarily run without fluid flowing through the bypass, which in turn improves the performance of the interior heater.

The horizontal flow radiator has an aluminum alloy core and a drain cock on the lower right side of the rear. The lower radiator mounts are located at the ends of the radiator tanks. The mounts have rubber bushings that sit on top of the car body rails. The upper part of the radiator is fastened with pins that are passed through rubber bushings mounted on the front bearing element (FEC) above the radiator. The radiator also has two connections for the gearbox oil pipes.

The upper and lower hoses are attached to the inlet and outlet pipes of the thermostat housing.

The expansion tank is installed in front of the left suspension support cup in the engine compartment. The expansion tank receives an excess amount of working fluid from the cooling system when it expands due to heating and, conversely, when the engine cools down, it compensates for its amount with a decrease in volume. Also, air accumulated in the coolant is discharged through this tank.

The transmission fluid cooler is installed on the side of the cold reservoir of the radiator. It is located in the middle of the left radiator tank.

To engine oil cooler (EOC) coolant comes from the bottom hose. The coolant is drained from the line between the radiator and the thermostat and sent to the oil cooler, after which it returns to the lower hose.

To supply additional air to the radiator core, especially when the vehicle is stationary, a viscous fan driven by the engine is used. This assembly works like a conventional viscous fan, but with an electronic viscous coupling drive. Electronic engine control unit (ECM) controls the fan speed by adjusting the degree of inclusion of the viscous coupling. The viscous coupling is switched on by the control unit based on the temperature of the coolant, the ambient temperature and the temperature of the oil in the gearbox, as well as the pressure in the air conditioning system. The applied fan has left rotation.

The speed of the viscous fan is optimally controlled by the ECM to suit all operating conditions.

NOTE: If the electrical connectors are disconnected from the viscous fan, it will rotate at "Idling", which can cause the engine to overheat. In this case, the ECM will store the corresponding DTC in memory.

Comments on this article