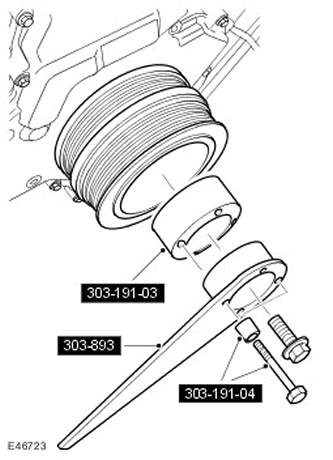

Special tool

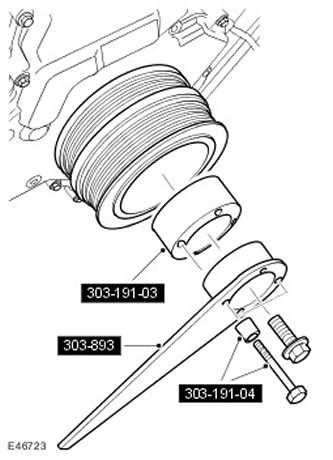

Adapter 303-191-03 Adapter 303-191-03 |  Bolts and bushings 303-191-04 Bolts and bushings 303-191-04 |  Crankshaft pulley locking tool 303-893 (LRT-12-080) Crankshaft pulley locking tool 303-893 (LRT-12-080) |

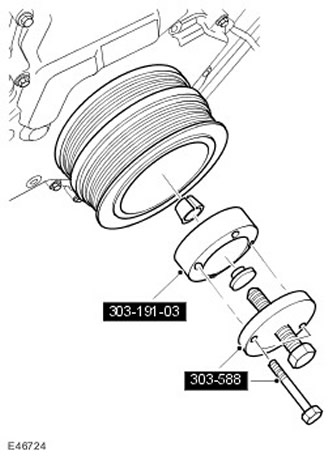

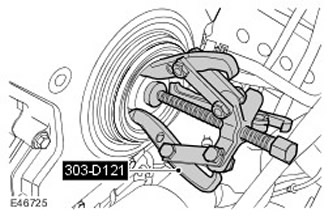

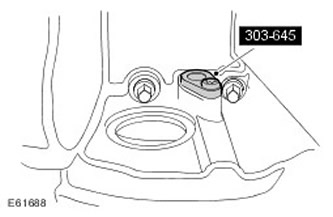

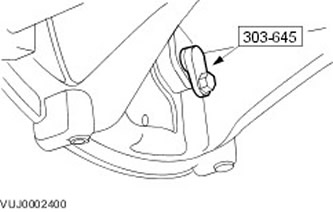

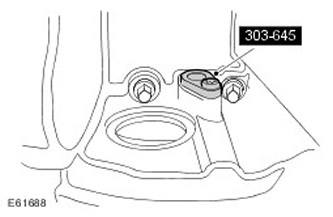

Crankshaft pulley puller 303-588 Crankshaft pulley puller 303-588 |  Crankshaft oil seal extractor 303-D121 Crankshaft oil seal extractor 303-D121 |  Position tool 303-645 Position tool 303-645 |

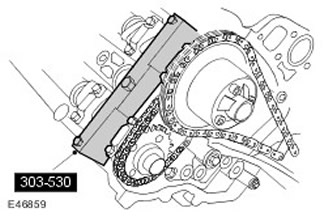

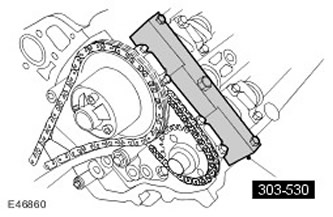

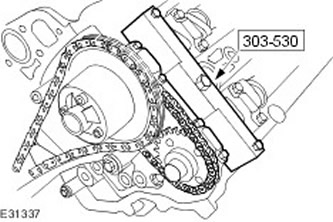

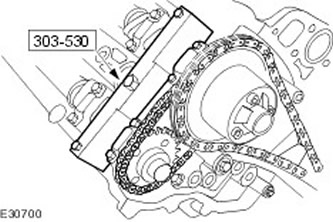

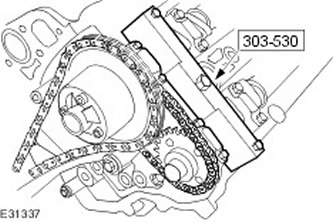

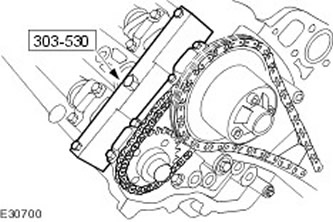

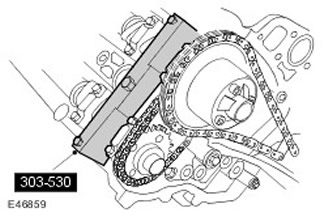

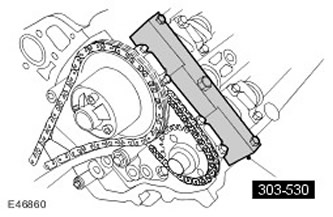

Camshaft installation/locking tool 303-530 Camshaft installation/locking tool 303-530 |  Crankshaft rear oil seal remover/mounter 303-538 Crankshaft rear oil seal remover/mounter 303-538 |  Crankshaft oil seal mounting tool 303-1100 Crankshaft oil seal mounting tool 303-1100 |

Crankshaft oil seal mounting tool adapter 303-1100-01 Crankshaft oil seal mounting tool adapter 303-1100-01 |

Removing

1. Disconnect the wire "masses" from the battery. For more information refer to Specification.

2.

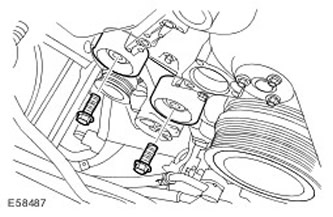

WARNING: Do not work near or under a vehicle that has only been jacked up. Be sure to support the car with special supports.

Raise and support the vehicle.

3. Remove the engine. For more information refer to Engine (12.41.01.99)

4. Place the engine on a motor stand.

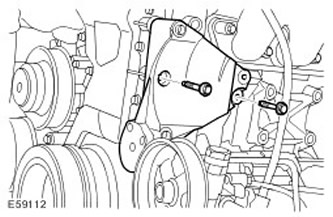

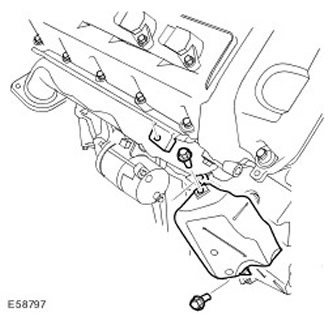

5. Remove the A/C compressor support bracket. Turn out two bolts.

6. Remove the cooling fan drive belt tensioner. Turn out a bolt.

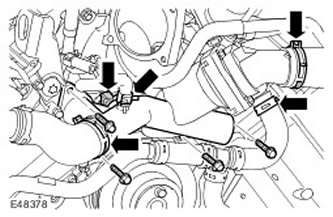

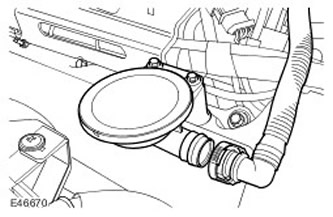

7. Remove the cooling system manifold.

- Release the clamps and disconnect the 4 coolant hoses.

- Turn out four bolts.

- Disconnect the engine coolant temperature sensor electrical connector (ECT).

8. Remove the water pump pulley and accessory drive belt idler pulleys. Turn out bolts.

9. Remove the exhaust manifold heat shield. Turn out two bolts.

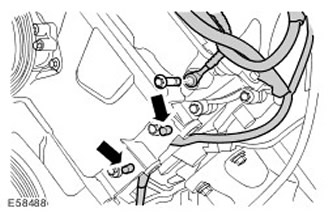

10. Disconnect the positive battery cable.

- Remove the battery positive cable cover.

- Loosen the nut.

- Disconnect the electrical connector.

- Turn out 3 bolts.

12. Remove the alternator support bracket. Turn out four bolts.

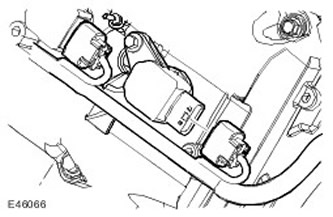

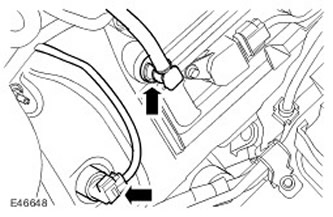

13. Disconnect the electrical connector for the engine oil temperature sensor.

14. Disconnect the engine oil pressure sensor electrical connector (EOP).

15.

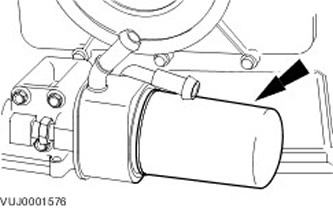

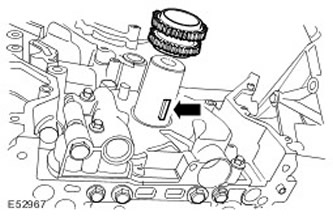

NOTE: Some oil will inevitably spill during this operation.

NOTE: Before disassembly, clean the common area of the elements.

Remove the oil filter.

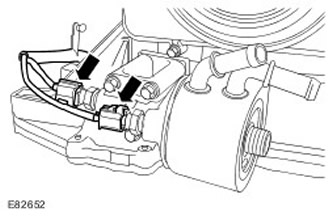

16. Remove the engine oil filter.

- Turn out 3 bolts.

- Remove and discard the O-ring.

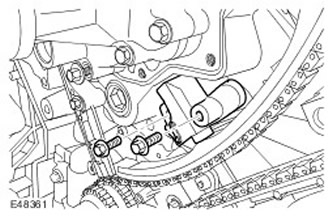

17.

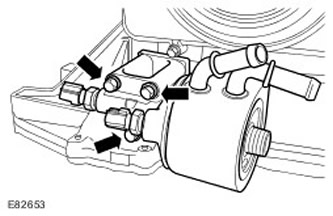

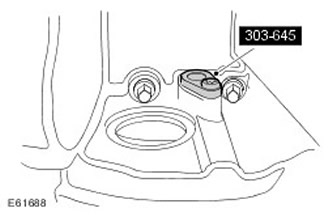

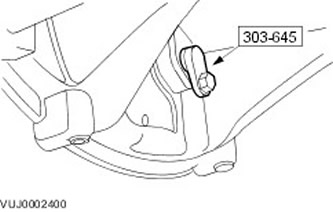

CAUTION: Under no circumstances use the crankshaft locating pin, 303-645, to lock the crankshaft when following the procedure below.

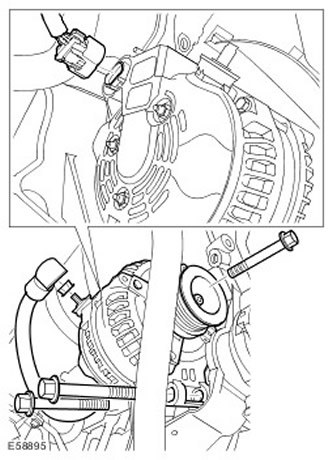

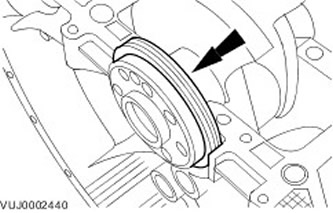

Block the crankshaft pulley with special tools.

18.

NOTE: The crankshaft pulley bolt is too tight.

Using the special tools, remove the crankshaft pulley mounting bolt.

- Discard the bolt.

- Disconnect special tools.

NOTE: The crankshaft pulley is difficult to remove.

Using the special tools, remove the crankshaft pulley.

- Pick up the retaining ring.

- Disconnect special tools.

20. Using the special tool, remove the front crankshaft seal and discard it.

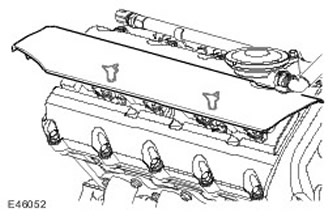

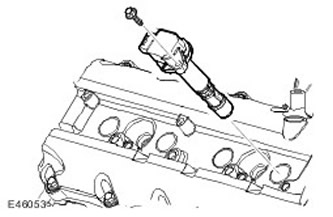

21. Remove the cover of the right direct ignition coils. Release two clamps.

22. Disconnect the right electric socket of the coil of direct ignition.

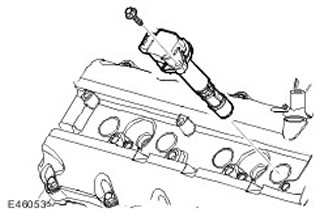

23. Remove the right direct ignition coil.

- Turn out a bolt.

- Remove and discard the O-ring.

24. Remove the remaining direct ignition coils.

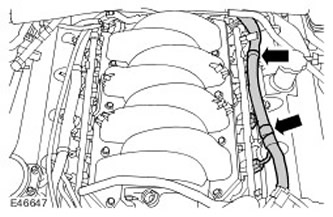

25. Disconnect the forced crankcase ventilation line (PCV).

26. Disconnect the electrical connector of the left variable valve timing solenoid valve (VCT).

27. Disconnect the breather from the cylinder head cover.

28. Release the engine wiring harness from the support bracket.

29. Disconnect the electrical connector of the right variable valve timing solenoid valve (VCT).

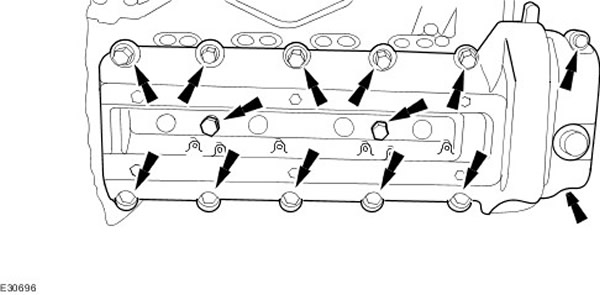

30.

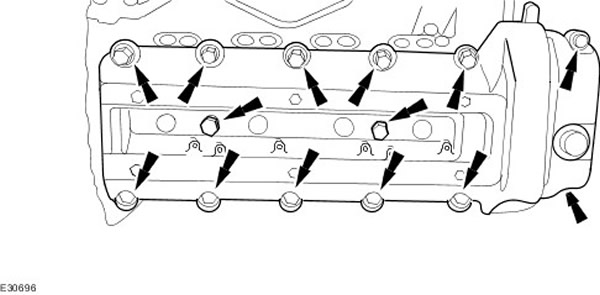

NOTE: Record the location of the bolts before removing them.

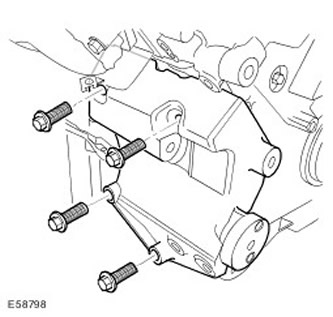

Remove the right cylinder head cover.

- Turn out 14 bolts of fastening of a cover of a head of cylinders.

- Remove the engine cover holder.

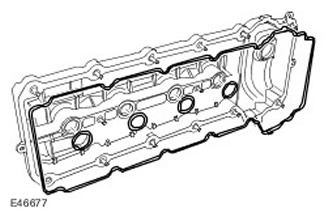

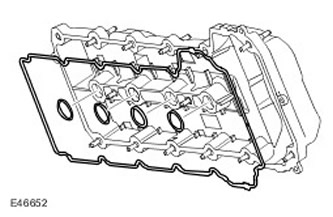

31. Remove and discard the right cylinder head cover gaskets. Remove seals and discard.

32. Remove the cover of the left direct ignition coils. Release two clamps.

33. Disconnect the left electrical connector of the direct ignition coil.

34. Remove the left direct ignition coil.

- Turn out a bolt.

- Remove and discard the O-ring.

35. Remove the remaining left direct ignition coils.

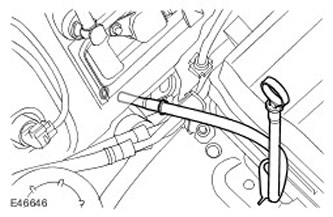

36. Remove the dipstick and oil level indicator tube.

- Remove the oil level dipstick.

- Loosen the nut.

- Pick up the handset.

- Remove and discard the O-ring.

37. Release the engine wiring harness from the support bracket.

38.

NOTE: Record the location of the bolts before removing them.

Remove the left cylinder head cover. Turn out 14 bolts of fastening of a cover of a head of cylinders.

39. Remove and discard the left cylinder head cover gaskets. Remove seals and discard.

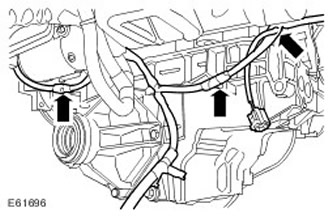

40. Release the engine wiring harness.

- Release two clamps.

- Turn out a bolt.

41. Remove the power steering pump support bracket. Turn out five bolts.

42. Release the wiring harness from the mount on the left side of the engine. Release the three clamps.

43. Release the wiring harness from the mount on the right side of the engine. Release the three clamps.

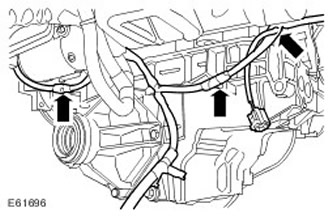

44. Remove the case of an intermediate support of a semiaxis.

- Turn out four bolts.

- Remove and discard the O-ring.

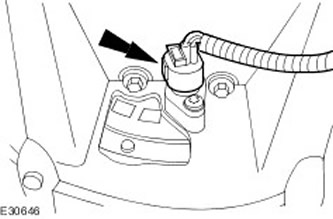

45. Disconnect the electrical connector of the crankshaft position sensor (TFR).

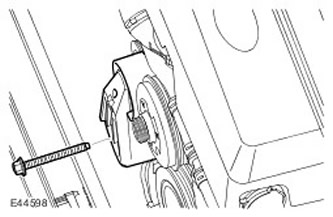

46. Remove the SKR sensor. Turn out a bolt.

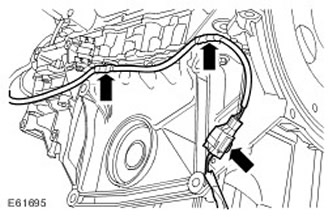

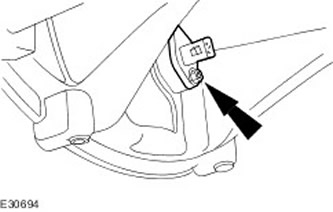

47.

NOTE: Install the special tool on the crankshaft sensor hole.

Block the crankshaft.

- Install the special tool.

- Screw in the screw.

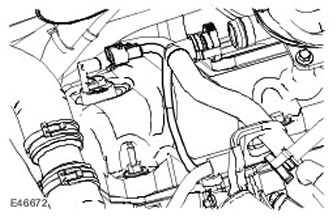

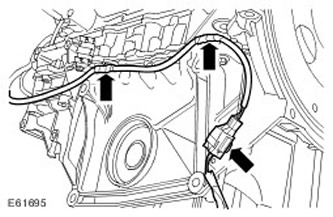

48. Remove the engine front cover.

- Remove 24 bolts.

- Remove and discard the gasket.

- Remove and discard 3 o-rings.

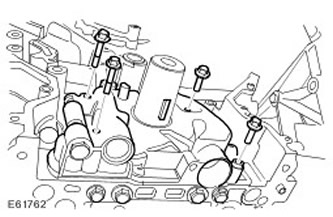

49. Remove the right VCT housing.

- Turn out 3 bolts.

- Remove the O-rings and discard them.

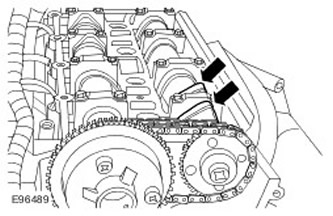

50. Install the special tool on the right cylinder head. Screw in 3 bolts.

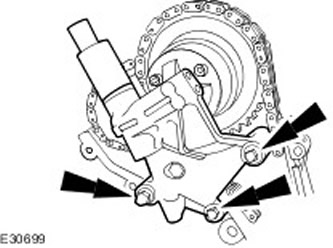

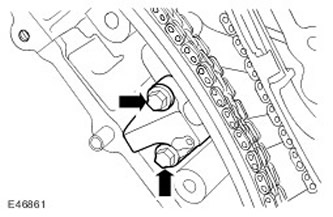

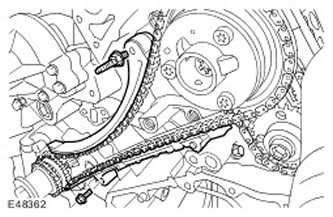

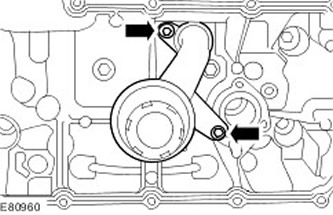

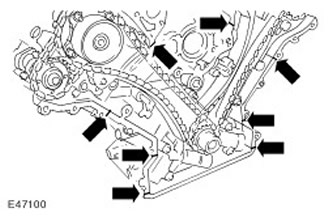

51. Remove the right primary timing chain tensioner. Turn out 2 bolts.

52. Remove the right row primary timing chain tensioner guide. Turn out a bolt.

53. Remove the right row primary timing chain.

54. Remove the left VCT housing.

- Turn out 3 bolts.

- Remove and discard o-rings.

55. Install the special tool on the left cylinder head. Screw in 3 bolts.

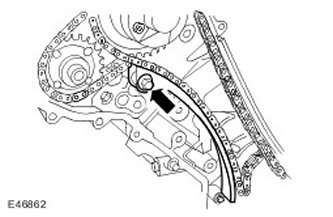

56. Remove the left row primary timing chain tensioner. Turn out two bolts.

57. Remove the upper and lower guides of the left primary timing chain tensioner. Turn out two bolts.

58. Remove the left row primary timing chain.

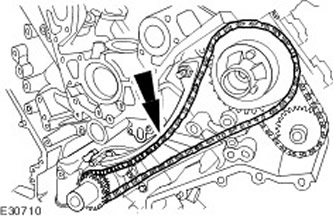

59.

NOTE: Mark the position of the crankshaft sprocket.

Remove the crankshaft sprocket. Remove the crankshaft sprocket pin.

60. Remove the special tool.

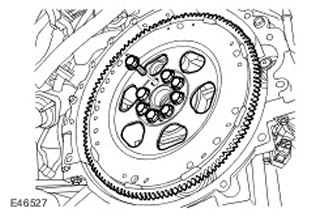

61. Remove the torque converter flexible plate. Remove and discard 8 bolts.

62.

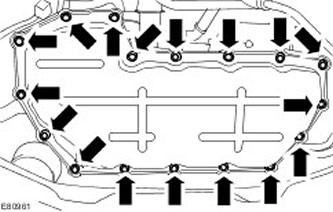

ATTENTION: Before turning out of bolts note their position.

Remove the oil pan.

- Remove 17 bolts.

- Remove and discard the gasket.

63. Remove the oil intake pipe with a strainer.

- Turn out two bolts.

- Remove and discard the O-ring.

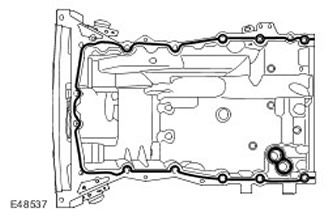

64. Remove the oil pan extension. Remove 18 bolts.

65. Remove the oil pump assembly.

- Turn out four bolts.

- Remove and discard the gasket.

- Clean the mating surfaces of the elements.

66. Remove the oil slinger plate. Turn out 6 bolts.

67.

WARNING: In order not to damage the crankshaft and piston parts, the engine must be upside down on the engine stand. Failure to do so may result in engine damage.

NOTE: If the crankshaft main bearing housing bolts have been punched, they must be discarded and new bolts installed.

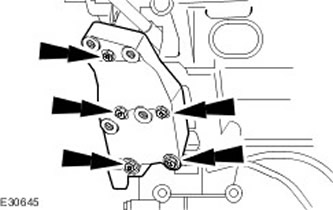

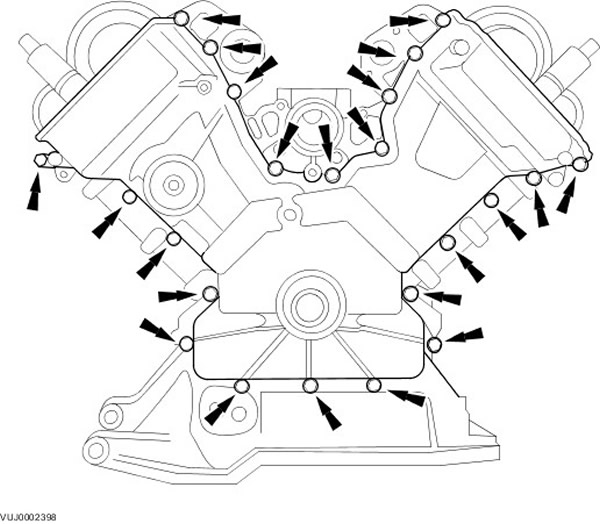

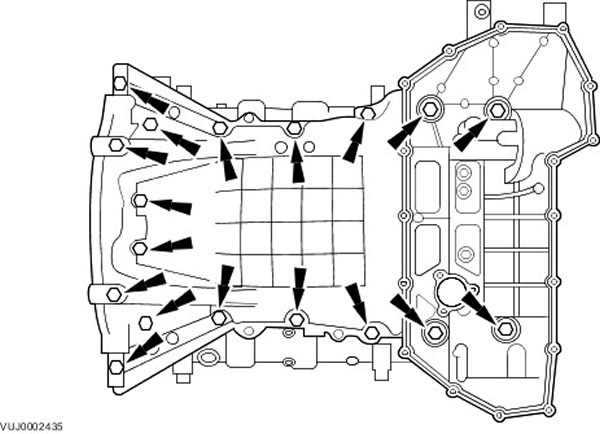

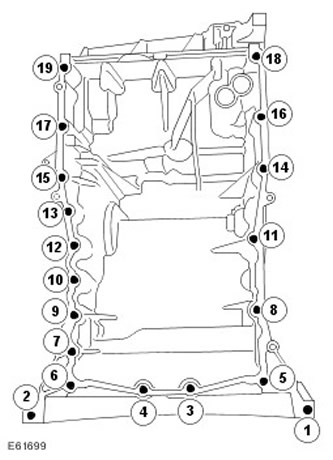

Remove the crankshaft main bearing housing. Turn out bolts of fastening of the case of the main bearing of a cranked shaft in the specified sequence.

68. Remove and discard the crankshaft rear oil seal.

Installation

1.

CAUTION: Use only a plastic mass scraper to remove sealant.

CAUTION: If new crankshaft main bearing housing bolts are installed, the bolts must be prestressed by installing the crankshaft main bearing housing without sealant and tightening the new bolts to rated torque. After pretensioning the bolts, remove the crankshaft main bearing housing. Failure to do so may result in vehicle damage.

Thoroughly clean all mating surfaces and reusable parts and inspect them for damage.

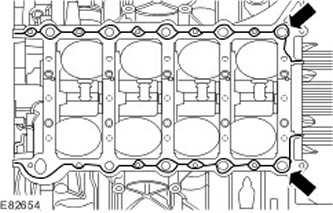

2.

NOTE: Install the crankshaft main bearing housing and tighten the bolts to rated torque within twenty minutes of applying the sealant.

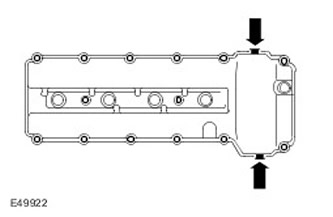

Apply a 2 mm bead to the cylinder block at the location shown. Use sealant WSS-M4G323-A4-RTV.

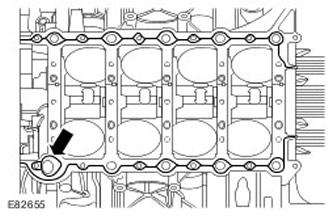

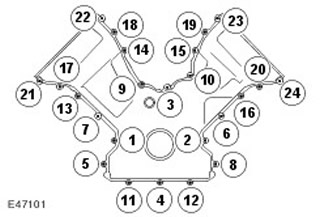

3.

NOTE: Install the crankshaft main bearing housing and tighten the bolts to rated torque within twenty minutes of applying the sealant.

Apply a 1 mm bead to the cylinder block at the location shown. Use sealant WSS-M4G323-A4-RTV.

4.

CAUTION: Before tightening the bolts, make sure all studs are securely seated in the crankshaft main bearing housing.

NOTE: Do not lubricate the crankshaft main bearing housing bolts.

NOTE: Do not rotate the crankshaft until all mounting bolts are torqued to specification.

NOTE: Mounting bolts must be tightened within twenty minutes of sealant application.

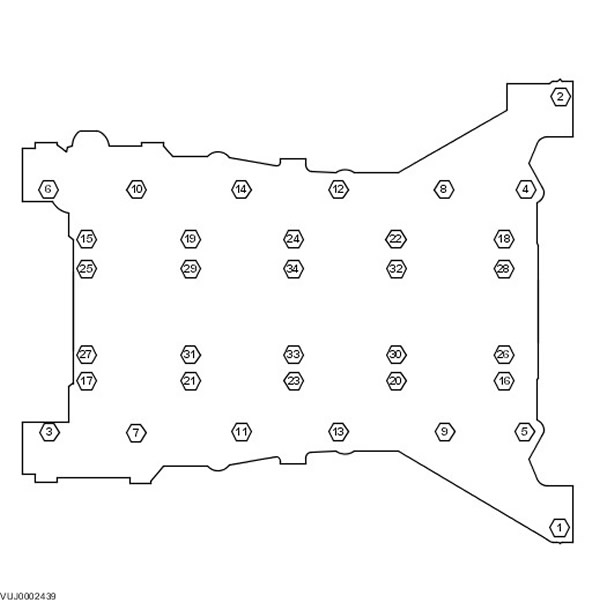

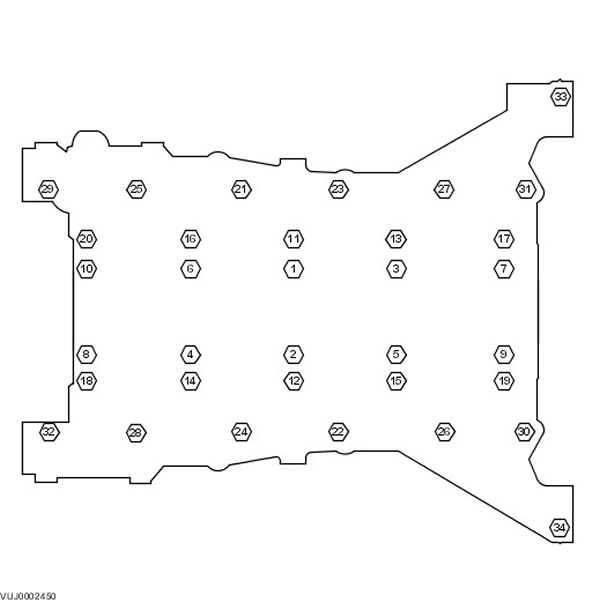

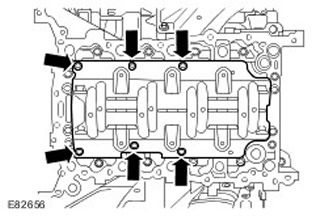

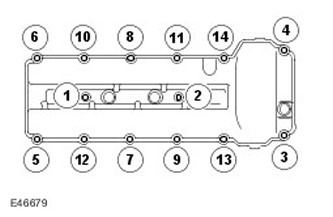

NOTE: Tighten the bolts in the sequence shown.

Install the crankshaft main bearing housing to the cylinder block.

- 1) Stage 1: Bolts 21-32, tightening torque 15 Nm.

- 2) Stage 2: Bolts 33-34, tightening torque 15 Nm.

- 3) Stage 3: Bolts 1-10, tightening torque 25 Nm.

- 4) Stage 4: Bolts 11-20, tightening torque 15 Nm.

- 5) Stage 5: Bolts 1-10, torque 35 Nm, and then another 135 degrees.

- 6) Stage 6: Bolts 11-20, torque 20 Nm, and then another 150 degrees.

- 7) Stage 7: Bolts 21-32, tightening torque 20 Nm, and then another 90 degrees.

- 8) Stage 8: Bolts 33-34, tightening torque 20 Nm, and then another 150 degrees.

- 9) Step 9: Pin the bolt heads to indicate they are reused.

5. Remove the special tool.

6. Remove the special tool of the spruce cylinder head.

7. Remove the special tool from the right cylinder head.

8.

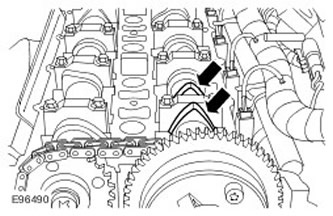

CAUTION: Make sure the intake camshaft lobes for cylinder #1 are vertical to the surface of the cylinder head.

Set right camshafts to neutral position.

9.

CAUTION: Ensure that the exhaust camshaft lobes for cylinder #2 are vertical to the surface of the cylinder head.

Set left camshafts to neutral position.

10.

CAUTION: Make sure the crankshaft is not binding.

CAUTION: The spark plugs must be removed to allow the engine to turn freely.

Gently turn the crankshaft two full turns to check for correct operation.

11. Install oil slinger plate. Tighten 6 bolts (tightening torque 6 Nm).

12.

NOTE: Carefully remove the shipping sleeve leaving the gland in place.

NOTE: Make sure the transport sleeve is correctly positioned and install a new oil seal on the crankshaft. Do not apply grease to the oil seal, transport sleeve and crankshaft.

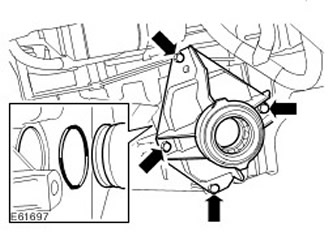

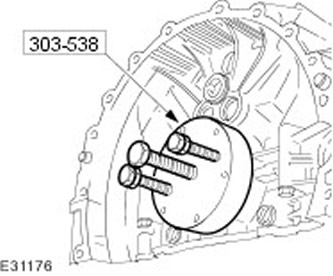

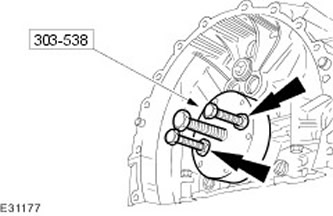

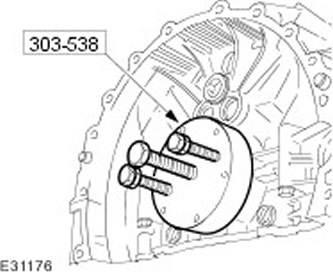

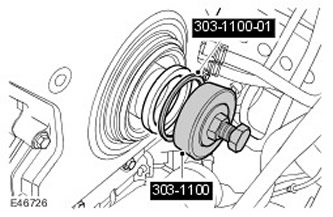

Using the special tool, install the crankshaft rear oil seal. Install the special tool on the crankshaft.

13.

CAUTION: Change the torque of the nut to properly seat the crankshaft rear oil seal.

Using the special tool, install the crankshaft rear oil seal.

14.

CAUTION: Make sure the crankshaft rear oil seal is installed correctly.

Remove the special tool.

15.

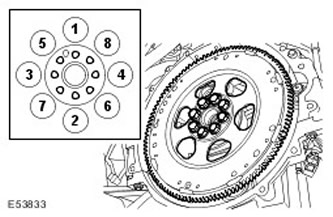

NOTE: Do not allow the flexible plate to rotate.

Install the torque converter flexible plate.

- Clean the contact surfaces of the parts.

- Tighten the bolts evenly, working in the sequence shown in two stages.

- Tighten the bolts (tightening torque 15 Nm).

- Tighten the bolts (tightening torque 110 Nm).

16.

CAUTION: The spark plugs must be removed to allow the engine to turn freely.

CAUTION: Do not turn the crankshaft counterclockwise.

CAUTION: Rotate the crankshaft clockwise to top dead center (TDC) for cylinder no. 1

Install the special tool.

17. Install the special tool on the left cylinder head.

18. Install the special tool on the right cylinder head.

19.

NOTE: Install a new gasket.

Install the oil pump assembly.

- Clean the mating surfaces of the elements.

- Install the gasket.

- Tighten the bolts (tightening torque 10 Nm).

NOTE: Install a new o-ring.

Install the oil pickup pipe with a strainer.

- Install the sealing ring.

- Tighten the M6 bolt (tightening torque 10 Nm).

- Apply sealant to the M5 bolts.

- Tighten M5 bolts (tightening torque 6 Nm).

- Clean the mating surfaces of the elements.

- Install the crankshaft sprocket pin.

23. Install the left row primary timing chain tensioner guides. Tighten the bolts (tightening torque 12 Nm).

24.

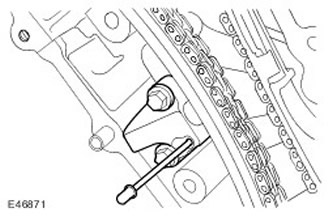

WARNING: While compressing the tensioner, do not release the ratchet until the tensioner piston is fully retracted into the hole. Failure to do so will result in damage to the ratchet.

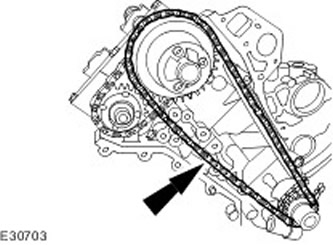

Install the left row primary timing chain tensioner.

- Using a 3 mm rod, fix the chain tensioner piston.

- Tighten the bolts (tightening torque 12 Nm).

- Remove the metal rod.

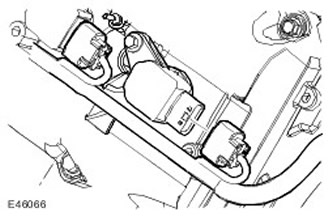

25.

CAUTION: Use new bolts.

NOTE: Install new o-rings.

Install the left variable valve timing solenoid valve housing (VCT).

- Install o-rings.

- Tighten the bolts (tightening torque 22 Nm).

- tighten the nut (tightening torque 10 Nm).

27. Install the right row primary timing chain tensioner guide. Tighten the bolts (tightening torque 12 Nm).

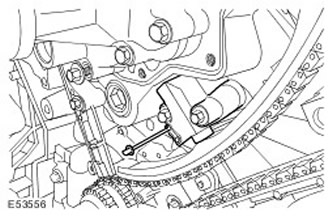

28.

WARNING: While compressing the tensioner, do not release the ratchet until the tensioner piston is fully retracted into the hole. Failure to do so will result in damage to the ratchet.

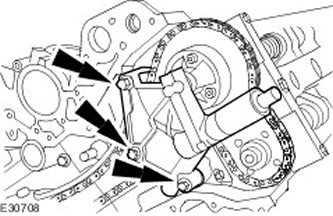

Install the right row primary timing chain tensioner.

- Using a 3 mm rod, fix the chain tensioner piston.

- Tighten the bolts (tightening torque 12 Nm).

- Remove the metal rod.

29.

CAUTION: Use new bolts.

NOTE: Install new o-rings.

Install the right variable valve timing solenoid valve housing (VCT).

- Install o-rings.

- Tighten the bolts (tightening torque 22 Nm).

- tighten the nut (tightening torque 10 Nm).

31. Remove the special tool from the left cylinder head.

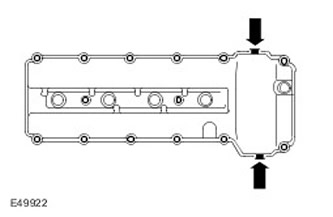

32. Remove the oil pan extension.

- Clean the mating surfaces of the elements.

- Apply sealant in the form of a 3 mm diameter bead to the area shown.

- Screw in the bolts, but do not tighten them all the way yet.

33. Tighten the oil sump bolts in sequence (tightening torque 20 Nm).

34. Remove the special tool. Turn out a bolt.

35. Install the SKR sensor. tighten bolt (tightening torque 8 Nm).

36. Attach the wiring harness to the bracket on the left side of the engine. Fasten with clips.

37. Attach the wiring harness to the bracket on the right side of the engine. Fasten the clamps.

38. Install the power steering pump support bracket. Tighten the bolts (tightening torque 25 Nm).

39.

NOTE: Install a new gasket.

NOTE: Install a new o-ring.

Install the engine front cover.

- Clean the mating surfaces of the elements.

- Apply sealant in the form of a roller with a diameter of 3 mm and a length of 12 mm in 8 places indicated.

- Install the gasket.

- Install the sealing ring.

40. Tighten the bolts evenly and progressively in the sequence shown (tightening torque 12 Nm).

41. Attach the engine wiring harness.

- Fasten with clips.

- tighten bolt (tightening torque 10 Nm).

NOTE: Install new seals.

Install new seals in the left cylinder head cover holes.

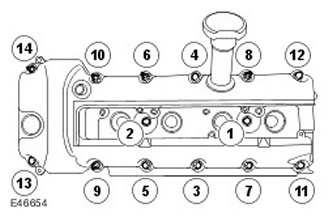

43.

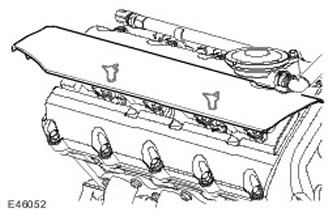

NOTE: Install a new gasket.

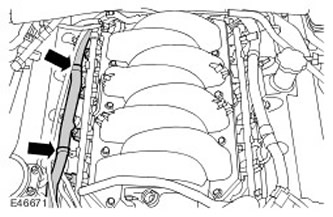

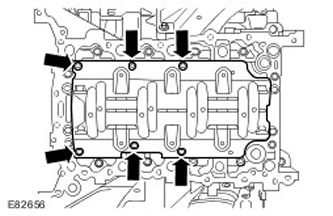

NOTE: Apply two strips of silicone gasket sealant as shown. The sealant beads should be 3 mm in diameter and 12 mm long. Install the cylinder head cover immediately after applying the sealant. The cylinder head cover must be installed directly on the head without smearing the sealant on the gasket.

Install the left cylinder head cover.

- Clean the mating surfaces of the elements.

- Install the cylinder head cover gasket.

44. Screw bolts of a cover of the left head of cylinders.

- Screw bolts of a cover of the left head of cylinders according to their former arrangement.

- Tighten bolts in sequence (tightening torque 12 Nm).

45. Connect the electrical connector of the left variable valve timing solenoid valve (VCT).

46. Insert the engine wiring harness into the support bracket.

47.

NOTE: Install a new o-ring.

With assistance, install the oil level gauge and tube.

- Clean the mating surfaces of the elements.

- Install the sealing ring.

- Lubricate the O-ring with clean engine oil.

- tighten the nut (tightening torque 6 Nm).

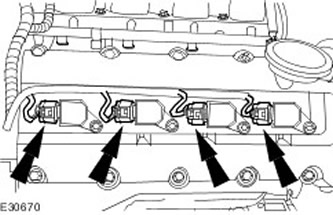

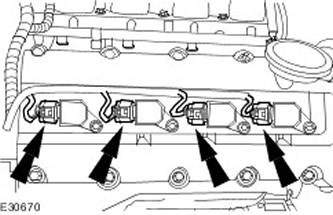

NOTE: Install new o-rings.

Install 4 left direct ignition coils.

- Install o-rings.

- Install 4 direct ignition coils.

- Tighten the bolts (tightening torque 6 Nm).

50. Establish a cover of the left coils of direct ignition.

51.

NOTE: Install new seals.

Install new seals in the right cylinder head cover holes.

52.

NOTE: Install a new gasket.

NOTE: Apply two strips of silicone gasket sealant as shown. The sealant beads should be 3 mm in diameter and 12 mm long. Install the cylinder head cover immediately after applying the sealant. The cylinder head cover must be installed directly on the head without smearing the sealant on the gasket.

Install the right cylinder head cover.

- Clean the mating surfaces of the elements.

- Install the gasket.

53. Screw bolts of a cover of the right head of cylinders.

- Screw in bolts of a cover of the right head of the block of cylinders according to their former location.

- Tighten bolts in sequence (tightening torque 12 Nm).

54.

NOTE: Install new o-rings.

Install 4 right direct ignition coils.

- Install o-rings.

- Install 4 direct ignition coils.

- Tighten the bolts (tightening torque 6 Nm).

56. Connect the electrical connector of the right variable valve timing solenoid valve (VCT).

57. Insert the engine wiring harness into the support bracket.

58. Connect the PCV line to the right cylinder head cover.

59. Clean the contact surfaces of the crankshaft pulley.

60. Using the special tool, install the crankshaft front oil seal.

- Lubricate the seal with clean engine oil.

- Use a scrap crankshaft bolt with a special tool.

- Disconnect special tools.

61. Install the crankshaft pulley. Lubricate the seal with clean engine oil.

62. Install the crankshaft pulley circlip.

63.

CAUTION: Before installing a new crankshaft pulley bolt, the threads in the pulley must be cleaned.

Install the crankshaft pulley bolt, but do not tighten it.

64.

CAUTION: Under no circumstances use the crankshaft locating pin, 303-645, to lock the crankshaft when following the procedure below.

Using the special tools, tighten the crankshaft pulley mounting bolt.

- Tighten the crankshaft pulley bolt (tightening torque 380 Nm).

- Remove special tools.

65. Install the oil filter housing.

- Clean the mating surfaces of the elements.

- Install a new sealing ring.

- Tighten the bolts (tightening torque 20 Nm).

67. Connect the electrical connector of the engine oil pressure sensor (EOP).

68. Connect the electrical connector of the engine oil temperature sensor.

69. Install the generator support bracket. Tighten 4 bolts (tightening torque 45 Nm).

70. Install the generator.

- Tighten 3 bolts (tightening torque 48 Nm).

- Connect the electrical connector.

- tighten the nut (tightening torque 10 Nm).

- Install the battery positive wire cover.

73. Install the auxiliary drive belt idler pulleys. Tighten the bolts (tightening torque 25 Nm).

74. Install the coolant pump pulley. Tighten the bolts (tightening torque 10 Nm).

75.

NOTE: Install new o-rings.

Install the cooling system manifold.

- Clear the details.

- Install o-rings.

- Connect 4 coolant hoses and install clamps.

- Install the wiring harness bracket.

- Tighten Torx Head Screws (tightening torque 10 Nm).

77. Install the cooling fan drive belt tensioner. tighten bolt (tightening torque 40 Nm).

78. Install the A/C compressor support bracket. Tighten the bolts (tightening torque 25 Nm).

79. Remove the engine from the stand.

80. Install the engine. For more information refer to Engine (12.41.01.99)

81. Connect the ground wire to the battery. For more information refer to Specification.

Comments on this article