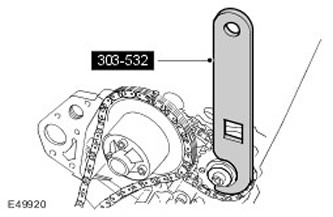

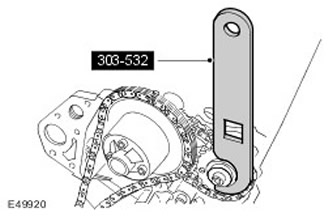

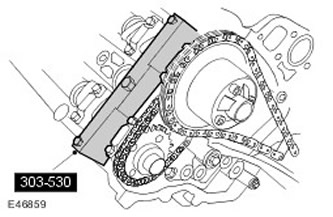

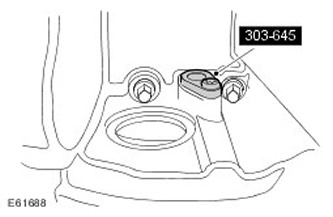

Special tool

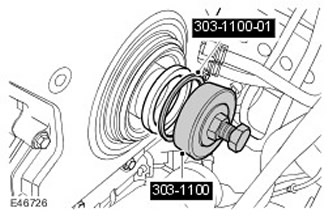

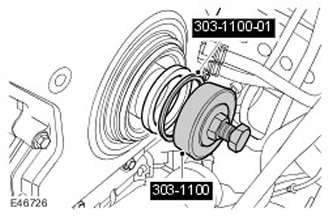

Valve timing tool 303-645 Valve timing tool 303-645 |  Camshaft Installer/Lock Tool 303-530 Camshaft Installer/Lock Tool 303-530 |  Crankshaft oil seal mounting tool adapter 303-1100-01 Crankshaft oil seal mounting tool adapter 303-1100-01 |

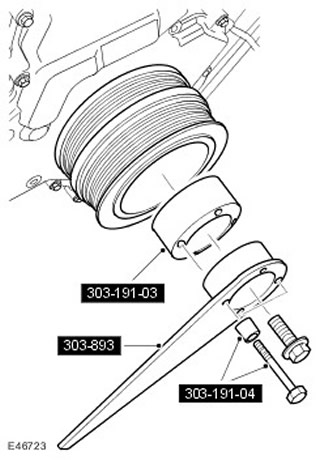

Adapter 303-191-03 Adapter 303-191-03 |  Crankshaft pulley locking tool 303-893 (LRT-12-080) Crankshaft pulley locking tool 303-893 (LRT-12-080) |  Bolts and spacers 303-191-04 Bolts and spacers 303-191-04 |

Tool for tensioning the timing chain 303-532 Tool for tensioning the timing chain 303-532 |

Assembly

1. Fix the engine on the engine stand.

- Adjust the position of the engine on the engine stand.

- Adjust the position of the motor stand legs.

- Install the engine on a motor stand.

- Fully tighten the motor stand leg nuts.

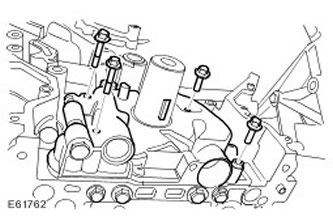

NOTE: Install a new gasket.

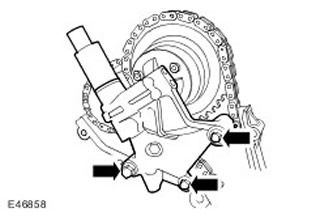

Install the oil pump assembly.

- Clean the mating surfaces of the elements.

- Install the gasket.

- Tighten the bolts to 10 Nm.

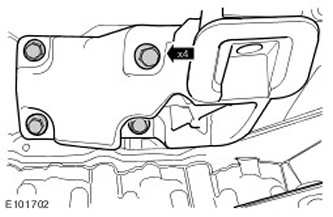

3. Install the baffle plate. Tighten 6 bolts to 6 Nm.

4.

NOTE: Install a new o-ring.

Install the oil pickup tube with strainer assembly.

- Install the sealing ring.

- Tighten the M6 bolt to 10 Nm.

- Apply sealant to the M5 bolts.

- Tighten the M5 bolts to 6 Nm.

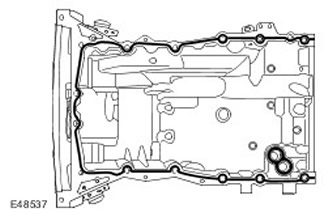

5. Install the oil pan.

- Clean the mating surfaces of the elements.

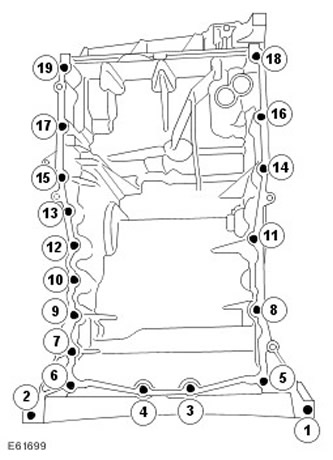

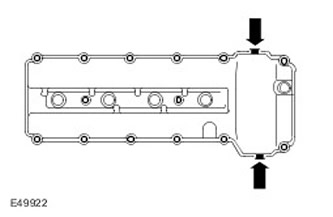

- Apply a 3 mm bead of sealant to the area shown.

- Screw in the bolts, but do not tighten them all the way yet.

6. Tighten the oil sump bolts in sequence to 20 Nm.

7.

NOTE: Stop the faceplate from rotating.

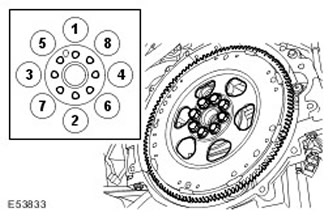

Install the faceplate.

- Clean the mating surfaces of the elements.

- Tighten the bolts evenly in 2 steps in the sequence shown.

- Tighten the bolts to 15 Nm.

- Tighten the bolts to 110 Nm.

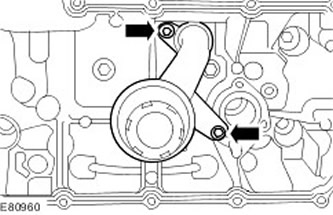

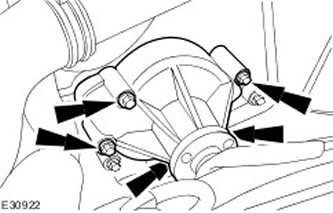

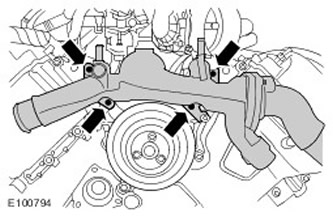

8. Install the coolant pump. Tighten 5 bolts to 10 Nm.

9.

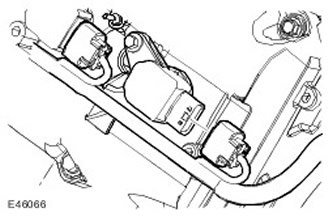

NOTE: There may be some differences from the pictures shown, but the basic information is correct.

Install knock sensors (KS). Tighten the bolts to 20 Nm.

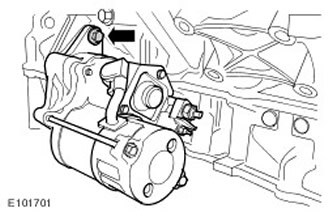

10. Install the starter. Install starter. Tightening torque: 45 Nm.

11. Connect the engine support bracket.

12.

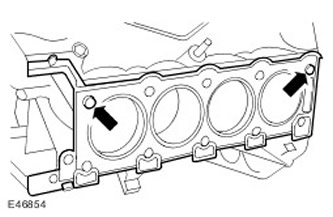

NOTE: The cylinder head gaskets must be installed on the cylinder block pins.

Install the right cylinder head.

- Clean the mating surfaces of the elements.

- Clean the dowel pins of the cylinder head.

- Install a new cylinder head gasket.

- With assistance, install the cylinder head.

- Repeat the operation on the left side.

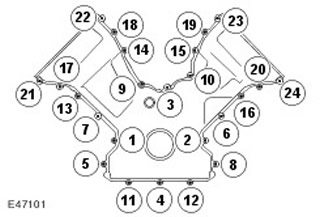

13.

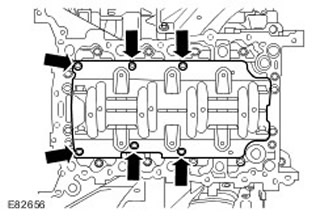

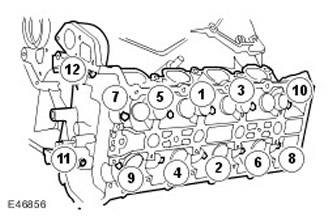

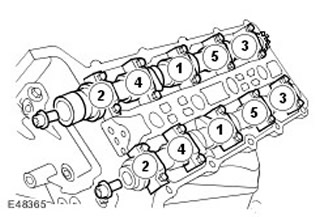

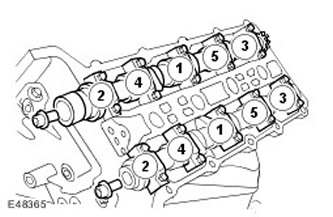

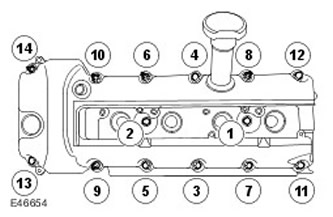

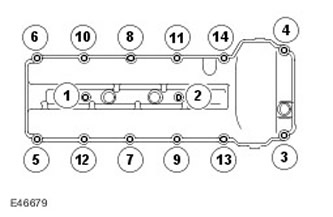

NOTE: Tighten bolts 1 to 10 in the sequence shown.

NOTE: Left side shown, right side similar.

Install the cylinder head bolts.

- Tighten the bolts to 20 Nm.

- Tighten the bolts to 35 Nm.

- Tighten bolts 1 to 10 another 90 degrees.

- Tighten bolts 1 to 10 another 90 degrees.

- Tighten M8 bolts 11 and 12 to 25 Nm.

- Repeat the operation on the left side.

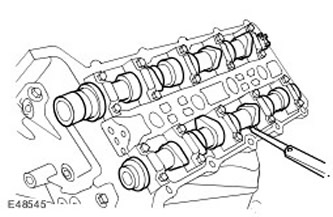

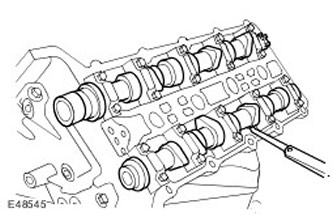

14. Install the left camshafts.

- Clean the mating surfaces of the elements.

- Lubricate the necks and cams of the camshafts.

16. Install the Torx head bolts to secure the sprockets to the camshafts.

17.

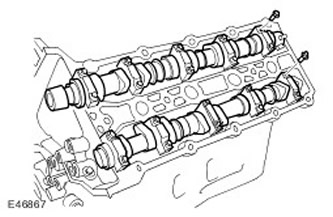

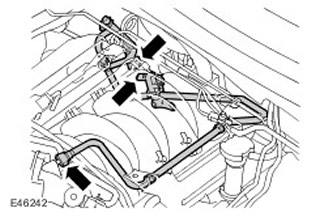

CAUTION: The camshaft lobes must be rotated 180 degrees from their respective valve lifters or the valve clearance will be incorrect.

Measure and record the valve clearances. Rotate the camshafts with Torx bolts.

18.

NOTE: Loosen the camshaft bearing caps evenly and gradually.

NOTE: Remove the camshaft bearing caps. Note: note their position, direction and markings. Each lid is marked with its position (number) and directions (arrow).

Remove camshafts. Remove 20 bolts.

19. Remove the valve lifters, replace them with selected pushers.

20. Install the camshafts.

- Lubricate the necks and cams of the camshafts.

- Clean the mating surfaces of the elements.

22.

CAUTION: The camshaft lobes must be rotated 180 degrees from their respective valve lifters or the valve clearance will be incorrect.

Check if the valve clearances are adjusted correctly.

- Rotate the camshafts with Torx bolts.

- Upon completion of the check, remove the Torx head bolts from the camshafts.

23. Repeat the operation for the right camshafts.

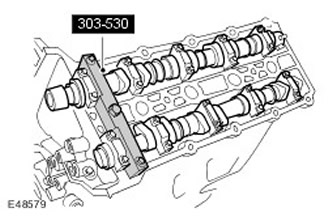

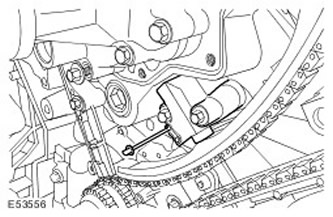

24. Install the special tool on the left cylinder head.

25.

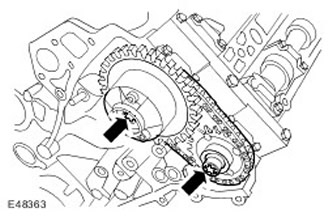

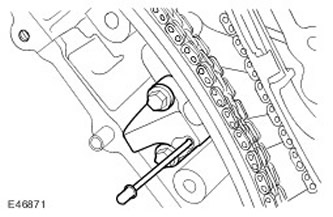

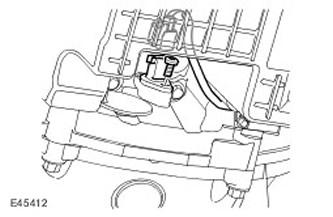

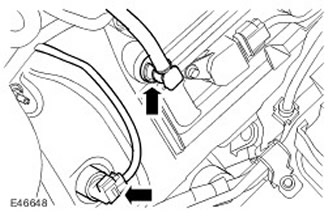

NOTE: The illustration shows the right side, the left side is the same.

Dip the left secondary timing chain tensioner piston. Using a metal rod with a diameter of 1 mm, hold the tensioner piston.

26. Screw in the bolts of the tensioner of the left secondary timing chain. Tighten the bolts to 12 Nm.

27.

NOTE: Lightly tighten the Torx head bolts to secure the sprocket to the camshaft; sprockets MUST move freely.

Install the left secondary timing chain and sprockets to the camshafts. Install the Torx head bolts to secure the sprockets to the camshafts.

28. Tension the secondary timing chain. Remove the metal rod.

29. Repeat the operation for the right camshafts.

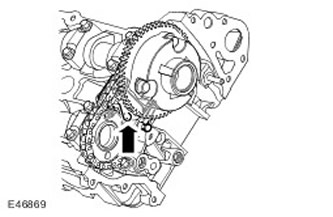

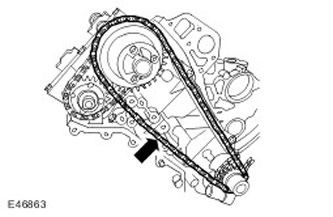

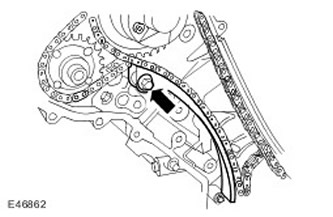

30.

NOTE: The illustration shows the right side, the left side is the same.

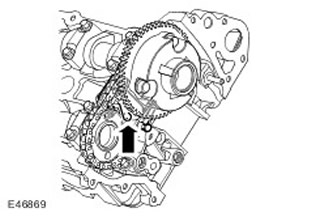

Install the left primary timing chain. Ensure that the loose section of the timing chain is on the tensioner side.

31. Install the left primary timing chain tensioner guide. Tighten the stud to 12 Nm.

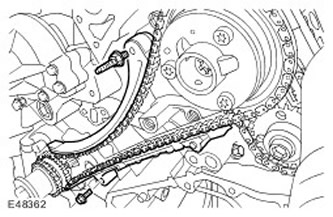

32.

WARNING: While compressing the timing chain tensioner, do not release the ratchet bar until the tensioner piston is fully lowered into the hole, otherwise the ratchet bar will be damaged.

Install the left primary timing chain tensioner.

- Using a metal rod with a diameter of 3 mm, hold the tensioner piston.

- Tighten the bolts to 12 Nm.

- Remove the metal rod.

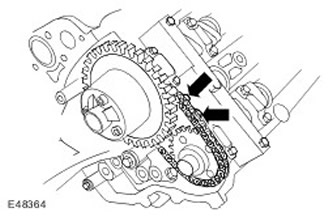

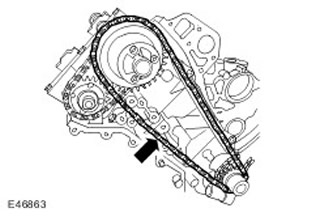

33.

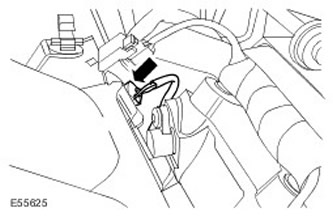

CAUTION: Apply counter-clockwise force to the special tool to tension the primary timing chain in its working area.

CAUTION: The intake camshaft sprocket bolt MUST be tightened up to the exhaust camshaft sprocket bolt. Failure to follow this procedure will result in engine damage.

Install the special tool on the exhaust camshaft sprocket.

- Tighten the intake camshaft sprocket bolt to 20 Nm, and then tighten it another 90 degrees.

- Tighten the exhaust camshaft sprocket bolt to 20 Nm, and then tighten it another 90 degrees.

34. Install the left variable valve timing oil control unit (VCT).

- Install new o-rings.

- Tighten the new bolts to 22 Nm.

- Tighten the nut to 10 Nm.

35. Put on the right primary timing chain. Ensure that the loose section of the timing chain is on the tensioner side.

36. Install the right primary timing chain tensioner guide. Tighten the bolts to 12 Nm.

37.

WARNING: While compressing the timing chain tensioner, do not release the ratchet bar until the tensioner piston is fully lowered into the hole, otherwise the ratchet bar will be damaged.

Install the right primary timing chain tensioner.

- Using a metal rod with a diameter of 3 mm, hold the tensioner piston.

- Tighten the bolts to 12 Nm.

- Remove the metal rod.

38.

CAUTION: Apply counter-clockwise force to the special tool to tension the primary timing chain in its working area.

CAUTION: The intake camshaft sprocket bolt MUST be tightened up to the exhaust camshaft sprocket bolt. Failure to follow this procedure will result in engine damage.

CAUTION: Use new bolts.

Install the special tool on the exhaust camshaft sprocket.

- Tighten the intake camshaft sprocket bolt to 20 Nm, and then tighten it another 90 degrees.

- Tighten the exhaust camshaft sprocket bolt to 20 Nm, and then tighten it another 90 degrees.

39. Install the right VCT oil control box.

- Install new o-rings.

- Tighten the new bolts to 22 Nm.

40. Remove the special tool from the left cylinder head.

41. Remove the special tool from the right cylinder head.

42. Remove the crankshaft locking tool. Remove the screw.

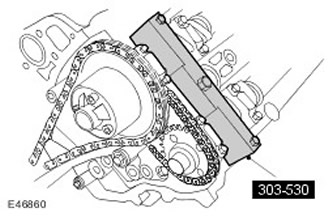

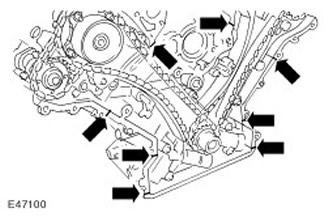

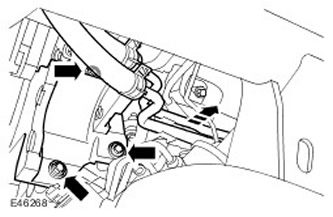

43. Install the engine front cover.

- Clean the mating surfaces of the elements.

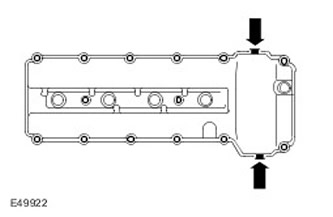

- Apply a bead of sealant with a diameter of 3 mm and a length of 12 mm to the 8 indicated places.

44. Evenly and gradually tighten the bolts in the sequence shown to 12 Nm.

45. Using the special tools, install the crankshaft front oil seal.

- Clean the mating surfaces of the elements.

- Lubricate the seal with clean engine oil.

- Use a scrap crankshaft bolt with a special tool.

46. Using the special tools, install the crankshaft front oil seal. Clean the mating surfaces of the elements.

47. Install the crankshaft pulley. Lubricate the seal with clean engine oil.

48. Install the crankshaft pulley circlip.

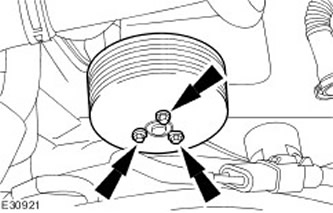

49.

CAUTION: Before installing a new crankshaft pulley bolt, the threads in the crankshaft pulley must be cleaned.

Install the crankshaft pulley bolt, but do not tighten it.

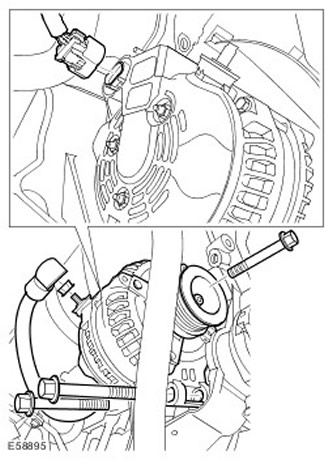

50.

CAUTION: Under no circumstances use the crankshaft locating pin, 303-645, to lock the crankshaft when following the procedure below.

Block the crankshaft pulley using special tools. Tighten the crankshaft pulley bolt to 380 Nm.

51. Remove special tools.

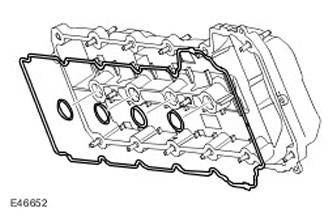

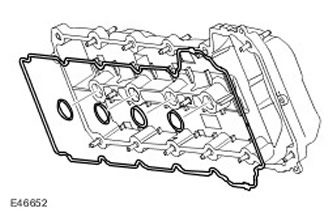

52. Install new seals in the holes in the cylinder head cover intended for candles. Install a new cylinder head cover gasket.

53.

NOTE: Apply two bead of silicone gasket sealant as shown. The sealant beads should be 3 mm in diameter and 12 mm long. Install the cylinder head cover immediately after applying the sealant. The cylinder head cover must be installed directly on the head without smearing the sealant on the gasket.

Install the cylinder head cover. Clean the mating surfaces of the elements.

54. Screw bolts of a cover of a head of cylinders.

- Screw in the cylinder head cover bolts in accordance with their previous location.

- Tighten the bolts in the order shown in the figure.

- Tighten the bolts to 12 Nm.

55. Install new seals in the holes in the cylinder head cover intended for candles. Install a new cylinder head cover gasket.

56.

NOTE: Apply two bead of silicone gasket sealant as shown. The sealant beads should be 3 mm in diameter and 12 mm long. Install the cylinder head cover immediately after applying the sealant. The cylinder head cover must be installed directly on the head without smearing the sealant on the gasket.

Install the cylinder head cover. Clean the mating surfaces of the elements.

57. Screw bolts of a cover of a head of cylinders.

- Screw in the cylinder head cover bolts in accordance with their previous location.

- Tighten the bolts to 12 Nm.

- Tighten the bolts in the order shown in the figure.

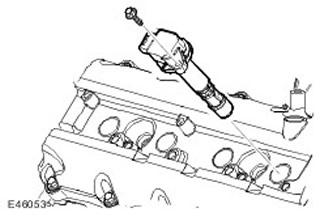

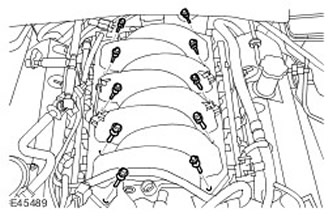

58. Install 8 direct ignition coils.

- Screw in 8 bolts.

- Tighten the bolts to 6 Nm.

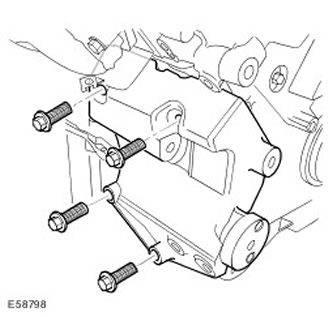

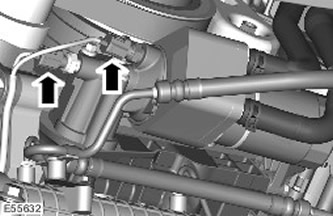

59. Install the generator support bracket.

- Clean the dowel pins.

- Clean the mating surfaces of the elements.

- Tighten the bolts to 45 Nm.

60. Install the air conditioner support bracket.

61. Install the coolant manifold. Tighten the bolts to 6 Nm.

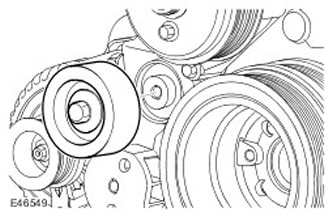

62. Install the coolant pump pulley. Tighten the bolts to 10 Nm.

63. Install the accessory drive belt idler pulley. Tighten the bolt to 25 Nm.

64. With assistance, install the intake manifold.

- Install gaskets.

- Tighten the bolts evenly and gradually to 20 Nm.

65. Install the purge valve.

- Secure the wiring harness with a clamp.

- Tighten the bolt to 6 Nm.

- Connect and secure the electrical connector.

66. Connect the starter positive wire. Fasten the cover.

67. Connect the engine oil temperature and pressure sensors.

68. Install the generator.

- Clean the mating surfaces of the elements.

- Tighten the bolts to 48 Nm.

- Connect the generator electrical connector.

- Lock the clamps.

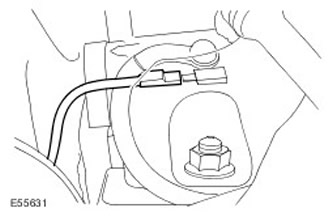

69. Install the crankshaft position sensor electrical connector (TFR). Connect the CKP sensor electrical connector.

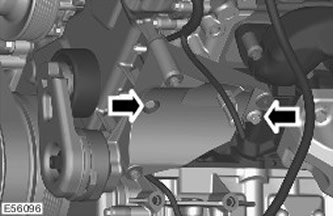

70. Install the power steering pump support bracket.

- Clean the mating surfaces of the elements.

- Tighten the bolts to 25 Nm.

- Clamp the transmission fluid cooler lines.

71. Connect and secure the electrical connectors of the CMP sensors. Repeat the operation on the right side.

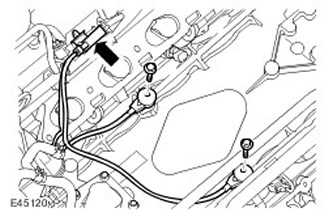

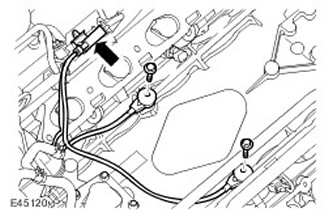

72.

NOTE: There may be some differences from the pictures shown, but the basic information is correct.

Connect the electrical connector of the KS sensor.

73. Dock the electrical connector of the engine coolant temperature sensor (ECT).

74. Connect the electrical connectors of the direct ignition coils.

- Install clamps.

- Repeat the above procedure on the other side.

75. Dock the variable valve timing solenoid valve electrical connector (VCT).

- Repeat the above procedure on the other side.

- Connect the ventilation hose to the cylinder head cover.

76. Connect an electric socket of weight of a head of cylinders.

- Screw in the bolt.

- Fasten 3 clips.

77. Install the direct ignition coil cover.

- Lock the clamps.

- Repeat the above procedure on the other side.

78. Remove the engine from the motor stand.

79. Install the engine.

Comments on this article