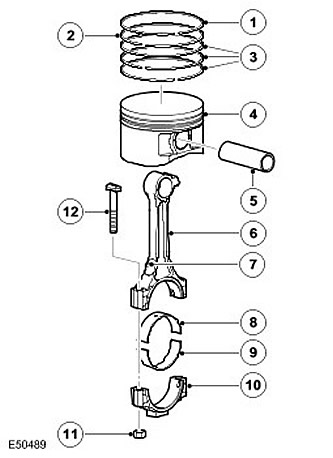

| Item name | Spare part number | Description |

| 1 | - | Top piston compression ring |

| 2 | - | Lower piston compression ring |

| 3 | - | Piston oil scraper rings |

| 4 | - | Piston |

| 5 | - | piston pin |

| 6 | - | connecting rod |

| 7 | - | oil nozzle hole |

| 8 | - | Upper connecting rod bearing |

| 9 | - | Connecting rod lower bearing |

| 10 | - | Connecting rod cover |

| 11 | - | screw |

| 12 | - | Bolt |

Lightweight aluminum alloy pistons with thermal expansion and piston pins floating in the piston bosses are offset to the pressure side and mounted on forged steel connecting rods. Pistons are assigned to one of four classes - 1, 2, 3 or 4. Pistons are marked so that they are correctly oriented in the cylinders; "arrow" should point towards the front of the engine.

The V6 petrol engine uses forged steel I-beam connecting rods. The piston pin provides a fixed fit for the top end of the connecting rod. The lower heads are divided horizontally.

Selected bearing shells in two thickness classes, nominal and undersized 0.25 mm, control the diametral clearance of the lower ends of the connecting rods. The upper and lower bearing shells of the lower heads have a simple shape without mounting tabs.

Each piston is equipped with two compression rings and an oil scraper ring. The top compression ring has a nitrided surface, which is obtained by diffusion of nitrogen into the surface layers of mild steel. The resulting nitrides provide increased hardness. The second compression ring is chrome plated. The wiper rings have stainless steel top and bottom guides and integral expansion rings.

Comments on this article