Removing

1. Disconnect the wire "masses" from the battery. For more information, refer to Specification

2. Drain the coolant. For more information, refer to Draining/Filling Coolant and Bleeding the Cooling System (26.10.01)

3. Go to the camshaft synchronization procedure. For more information, refer to Gas distribution

4. Remove the exhaust manifold. For more information refer to Left Exhaust Manifold (30.15.10)

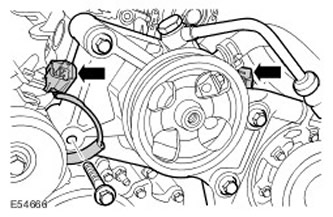

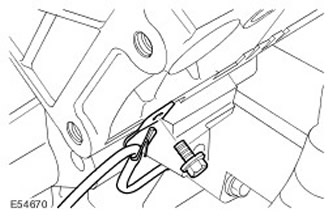

5. Release the wiring harness bridge to gain access. Turn out a bolt.

6. Move the A/C compressor support bracket aside.

- Turn out four bolts.

- Release the knock sensor electrical connector clips.

- Take the bracket aside and tie.

7. Remove the left hydraulic timing chain tensioner. Clean the mating surfaces of the parts.

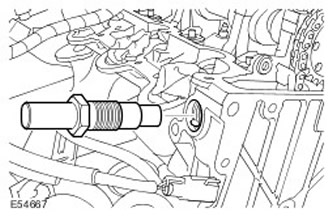

8. Turn out a Torx bolt of fastening of a directing chain. Remove and discard the O-ring.

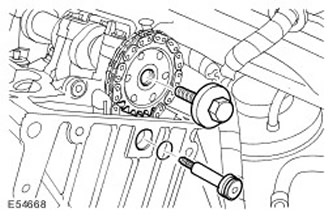

9. Turn out a bolt of an asterisk of a camshaft.

- Remove the sprocket from the camshaft.

- Fasten the chain and guide with wire.

10.

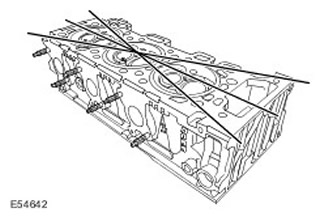

CAUTION: Loosen the bolts gradually in a criss-cross pattern.

Remove 10 cylinder head bolts. Discard the bolts.

11. Remove the left row cylinder head assembly.

- Release the knock sensor harness clamp.

- Turn out a bolt.

12. Remove and discard the cylinder head gasket.

- Clean the cylinder head dowel pins.

- Clean and inspect the cylinder head and cylinder block.

13.

NOTE: Loosen the camshaft bearing caps evenly and gradually.

NOTE: Note the position in which the part was installed.

NOTE: Do not proceed with dismantling if the part is being removed only for access.

Remove the camshaft bearing caps.

- Remove eight bolts.

- Remove the camshaft oil supply line.

Installation

1. Install the camshaft.

- Clean the mating surfaces of the parts.

- Lubricate the parts with clean engine oil.

2.

NOTE: Note the position in which the part was installed.

Install the camshaft bearing caps.

- Clean the mating surfaces of the parts.

- Lubricate the parts with clean engine oil.

NOTE: After installing the bolts, make sure the camshaft rotates freely.

Install the camshaft oil supply line.

- Thoroughly clean and check the oil supply line.

- Fill the oil supply line with clean engine oil.

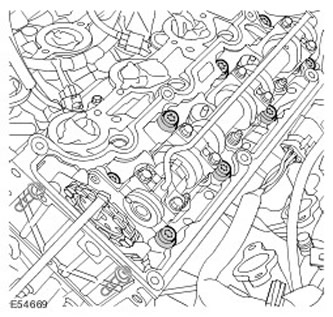

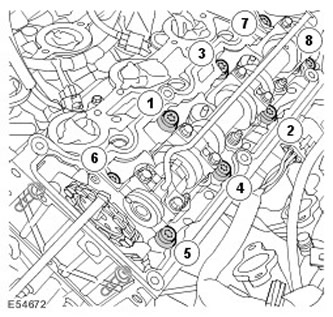

- Tighten the bolts evenly in 2 steps in the sequence shown.

- Tighten the bolts (tightening torque 6 Nm).

- Tighten the bolts (tightening torque 16 Nm).

5. Check up a surface of a head of the block of cylinders on presence of deformation in longitudinal and cross directions and on diagonals. For more information, refer to Specification

6.

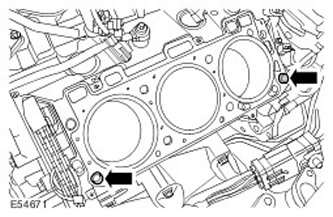

CAUTION: The cylinder head gasket must be installed on the cylinder block pins.

Install a new cylinder head gasket.

7. Establish a head of the block of cylinders of the left number in gathering.

- Install the knock sensor bracket.

- tighten bolt (tightening torque 10 Nm).

NOTE: Tighten bolts 1 to 8 in the sequence shown. The M12 bolts are tightened in three steps.

Wrap bolts of fastening of a head of the block of cylinders.

- Lubricate the new cylinder head bolts with clean engine oil.

- Tighten M12 bolts (tightening torque 30 Nm), and then another 80 degrees.

- Tighten the M12 bolts another 80 degrees.

- Tighten M8 bolts (tightening torque 35 Nm).

9. Install the exhaust manifold. For more information refer to Left Exhaust Manifold (30.15.10)

10. Install the chain guide Torx bolt.

- Install a new sealing ring.

- tighten bolt (tightening torque 10 Nm).

- Clean the mating surfaces of the parts.

- Clean the mating surfaces of the parts.

- Tighten the bolts (tightening torque 45 Nm).

- Fasten the wiring harness.

- Tighten the knock sensor clamp bolt (tightening torque 10 Nm).

13. Adjust the valve timing. For more information, refer to Gas distribution

14. Install the wiring harness bridge. tighten bolt (tightening torque 45 Nm).

15. Connect the wire "masses" to the battery. For more information, refer to Specification

16. Fill the cooling system with coolant and remove air from the system. For more information, refer to Draining/Filling Coolant and Bleeding the Cooling System (26.10.01)

Comments on this article