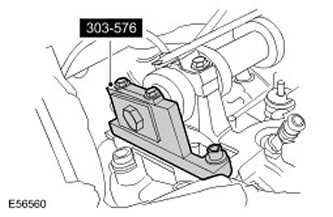

Special tool

Camshaft alignment tool 303-1146 Camshaft alignment tool 303-1146 |  Tool for setting TDC / crankshaft lock 303-573 Tool for setting TDC / crankshaft lock 303-573 |  Camshaft bolt tool 303-575 Camshaft bolt tool 303-575 |  Camshaft bolt socket 303-565 Camshaft bolt socket 303-565 |

Camshaft locking tool adapter 303-576 Camshaft locking tool adapter 303-576 |  Camshaft sprocket adjustment/locking tool 303-597-01 Camshaft sprocket adjustment/locking tool 303-597-01 |  Camshaft timing chain tensioning tool 303-571 Camshaft timing chain tensioning tool 303-571 |

1. Check camshaft timing.

2. Disconnect a wire of weight from the storage battery. Specification

3. Remove both cylinder head covers.

4. Turn the crankshaft clockwise so that one cylinder is at TDC. Make sure the camshaft lobes are at the rear.

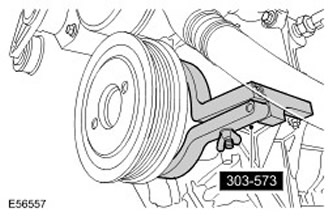

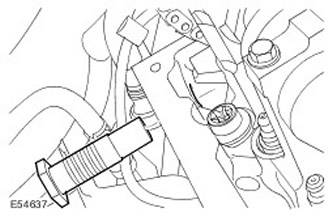

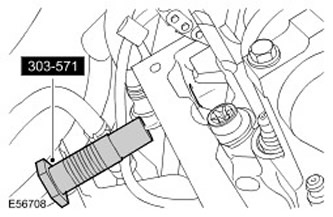

5. Block the crankshaft.

- Install the special tool.

- Tighten the screw.

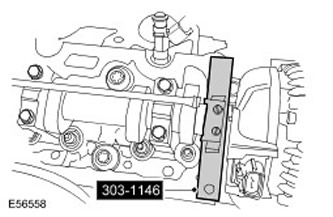

6. Install the special tool in the slot of the camshaft. In this case, the base of the special tool must be in contact with the cylinder head. If the special tool can pass without resistance from one side of the cylinder head to the other, the camshaft is correctly adjusted. Repeat the procedure for the other camshaft. If it is determined that both camshafts are adjusted correctly, no further action is required.

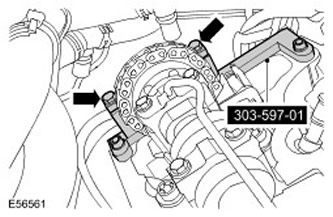

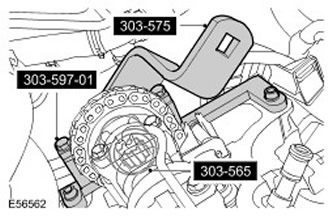

7. If the camshaft is not synchronized correctly, adjust. Note that both camshafts must be re-timed with the camshaft roller tappets removed.

8. Remove the camshaft roller tappets. Camshaft roller tappet (12.29.57)

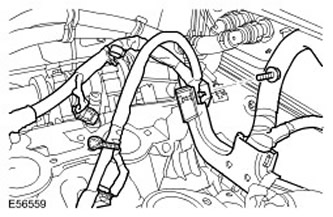

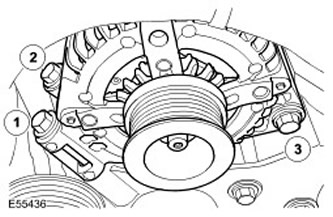

9. Move the generator to the side to gain access. Turn out 3 bolts.

10. Turn out a bolt of fastening of a plait of electroconducting of the right head of cylinders. To gain access, move the wiring harness bracket to the side.

11.

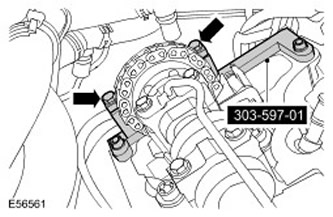

CAUTION: Using a centering tool to loosen the camshaft sprocket mounting bolt will damage the crankshaft.

NOTE: The camshaft alignment slot is off-center. The slot of a properly adjusted shaft should be horizontal under the center line.

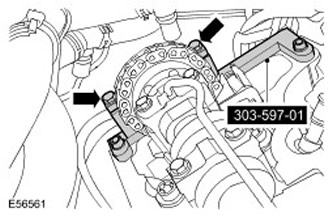

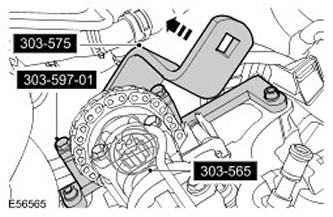

Install the special tool for adjusting the camshaft.

- Clean the contact surfaces of the parts.

- Tighten the bolts with a torque of 10 Nm.

- Lock the camshaft and tighten the special tool bolt to 45 Nm.

12. Establish the special tool on a head of cylinders of the right number.

- Clean the contact surfaces of the parts.

- Tighten the bolts with a torque of 10 Nm.

- Tighten the bracket bolts to 10 Nm.

13.

CAUTION: The right camshaft sprocket bolt has a left hand thread.

Using the special tool, loosen the right camshaft sprocket bolt. Loosen and discard the bolts.

14. Loosen the special tool bracket bolts.

15.

CAUTION: Before disconnecting or removing parts, make sure that the area around the contact surfaces and connections is clean. Plug all open connections to avoid contamination of the system.

Remove the right hydraulic timing chain tensioner.

16. Install the special tool. Clean the contact surfaces of the parts.

17. Tighten the bracket bolts with a torque of 10 Nm.

18. Using a special tool, tighten the camshaft sprocket bolt with a torque of 20 Nm, and then another 100 degrees.

19. Remove special tools.

20. Install the right hydraulic timing chain tensioner.

- Install a new seal.

- Clean the contact surfaces of the parts.

- Tighten the tensioner with a torque of 44 Nm.

NOTE: When changing the position of either camshaft, both camshafts MUST be re-adjusted.

NOTE: The left camshaft sprocket bolt is a right hand thread.

Repeat the above procedure to adjust the left camshaft timing.

22. Install the camshaft roller tappets. Camshaft roller tappet (12.29.57)

23.

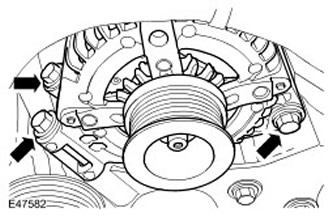

CAUTION: Tighten the bolts in the sequence shown.

Install the generator.

- Clean the contact surfaces of the parts.

- Tighten the bolts (tightening torque 45 Nm).

24. Connect a wire of weight to the storage battery. Specification

Comments on this article