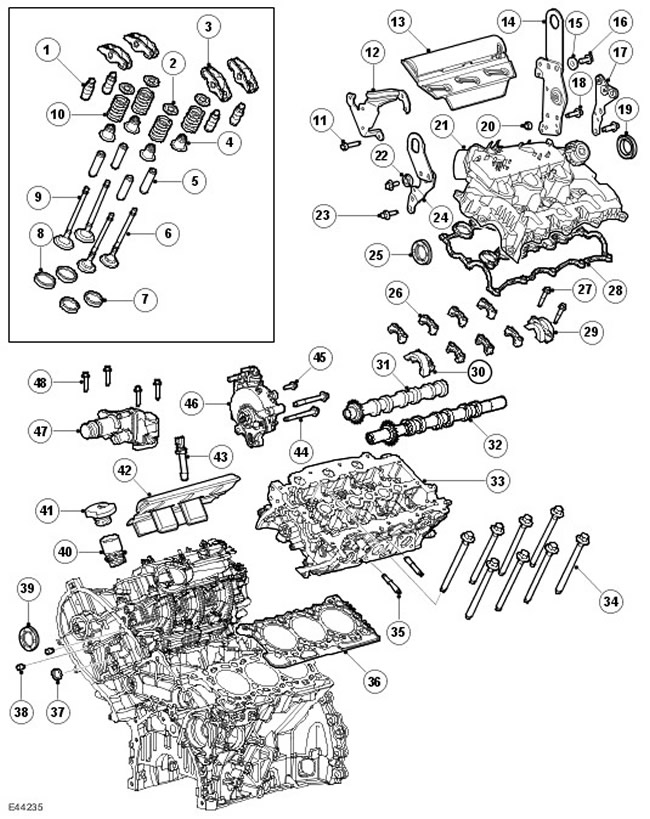

| Item name | Spare part number | Description |

| 1 | - | Valve clearance hydraulic compensators |

| 2 | - | Valve spring plates |

| 3 | - | Roller levers |

| 4 | - | Valve stem seals |

| 5 | - | Valve guides |

| 6 | - | exhaust valves |

| 7 | - | intake valves |

| 8 | - | Exhaust valve seats |

| 9 | - | Inlet valve seats |

| 10 | - | Valve springs |

| 11 | - | Bolt |

| 12 | - | bracket |

| 13 | - | Lid |

| 14 | - | Mounting eye |

| 15 | - | Washer |

| 16 | - | Bolt |

| 17 | - | bracket |

| 18 | - | Bolt |

| 19 | - | Seal |

| 20 | - | Lid |

| 21 | - | Intake manifold cover assy |

| 22 | - | Washer |

| 23 | - | Bolt |

| 24 | - | Mounting eye |

| 25 | - | Seal |

| 26 | - | Camshaft bearing caps |

| 27 | - | bolts |

| 28 | - | Pad |

| 29 | - | Seal housing and camshaft bearing cap |

| 30 | - | Seal housing and camshaft bearing cap |

| 31 | - | intake camshaft |

| 32 | - | exhaust camshaft |

| 33 | - | Left cylinder head |

| 34 | - | Cylinder head bolts |

| 35 | - | exhaust manifold studs |

| 36 | - | Laying of the left head of cylinders |

| 37 | - | Stub |

| 38 | - | Stub |

| 39 | - | Seal |

| 40 | - | Oil filler tube |

| 41 | - | Oil filler cap |

| 42 | - | Lid |

| 43 | - | nozzles |

| 44 | - | bolts |

| 45 | - | Bolt |

| 46 | - | Vacuum pump |

| 47 | - | Water outlet assembly |

| 48 | - | bolts |

Cylinder heads

The die-cast aluminum cylinder heads of each row are not interchangeable. Each cylinder head is attached to the cylinder block with 8 deep-seated bolts to reduce deformation. The cylinder head bolts are located under the camshafts: 4 under the intake camshaft and 4 under the exhaust camshaft. 2 hollow pins ensure the alignment of each cylinder head with the cylinder block.

NOTE: With the camshafts installed, the head and cylinder mounting bolts are not accessible.

NOTE: The cylinder head must not be remachined.

There are 4 channels in the cylinder head (2 exhaust and 2 intake), formed at the locations of each cylinder. One of the inlet channels is helical and acts as a swirl channel, the other is located on the side, creating a tangential flow, and acts as a charging channel.

The six fuel injection injectors are centrally located, one injector above each cylinder, with each injector attached to the cylinder head with a clip and 2 M6 x 35 bolts. For more information, refer to Electronic Engine Controls (303-14C Electronic Engine Controls - 2.7L Diesel). For more information refer to Fuel Charging and Controls (303-04C Fuel Charging and Controls - 2.7L Diesel).

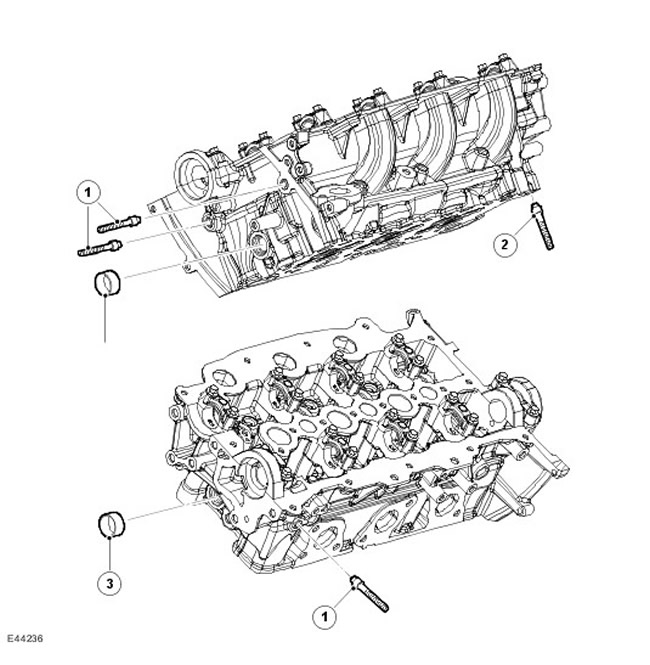

| Item name | Spare part number | Description |

| 1 | - | Wiring harness connector |

| 2 | - | glow plugs |

The glow plugs are located centrally on the inlet side of the cylinder head, between the 2 inlet ports of each cylinder. For more information refer to Electronic Engine Controls (303-14C Electronic Engine Controls - 2.7L Diesel).

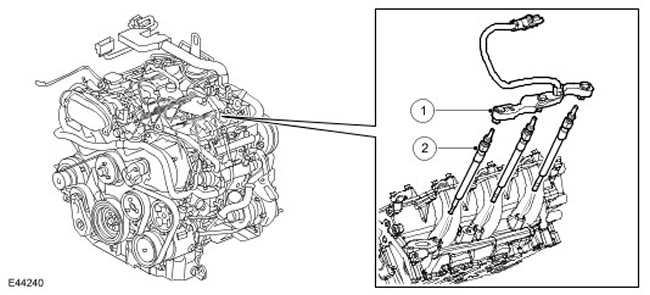

| Item name | Spare part number | Description |

| 1 | - | Sensors for camshaft position (SMR) |

The camshaft position sensor is located in the flange hole on the left front side of the left cylinder head. On the asterisk (gear) The exhaust camshaft of the left cylinder head has a target used by the sensor to determine the position of the shaft. For more information refer to Electronic Engine Controls (303-14C Electronic Engine Controls - 2.7L Diesel)

Engine mounting lugs are bolted to the cylinder head: two at the rear (one for each head) and one in front.

Camshaft covers

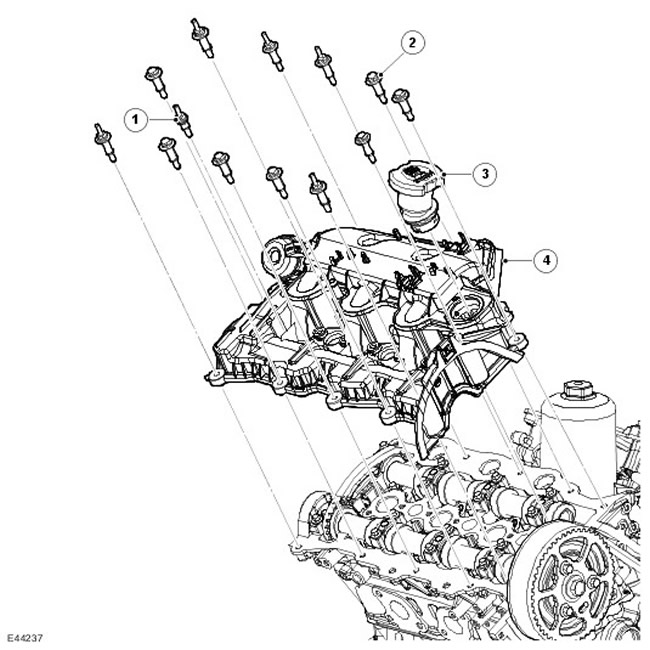

| Item name | Spare part number | Description |

| 1 | - | Threaded rod M6 x 40, 6 pcs. |

| 2 | - | Bolt M6 x 40 x 7 |

| 3 | - | Oil filler hole |

| 4 | - | Camshaft cover of the right row of cylinders, assy |

The camshaft covers are made from vinyl ester composite material. The right bank camshaft cover has a full load breather port and an oil filler neck. The camshaft cover of the left bank of cylinders has a hole for a partial load breather. For more information refer to Engine Emission Control (303-08C Engine Emission Control - 2.7L Diesel).

The joints between the camshaft covers and the cylinder heads are sealed with recessed silicone rubber gaskets. Together with the spacers and seals on the camshaft roof fasteners, they also keep the covers from coming into direct contact with the cylinder heads, thus reducing noise levels.

Cylinder head gasket

The cylinder head gaskets are three-ply steel gaskets. There are 5 sizes of gaskets, which differ in thickness. The selection of the required size depends on the maximum piston protrusion. The thickness of the gasket is determined by the number of teeth cut into the front of the gasket.

Gasket table

| Piston protrusion (mm) | Gasket thickness (mm) | Identification data |

| 0,541 - 0,590 | 1,12 | 1 |

| 0,591 - 0,640 | 1,17 | 2 |

| 0,641 - 0,690 | 1,22 | 3 |

| 0,691 - 0,740 | 1,27 | 4 |

| 0,741 - 0,790 | 1,32 | 5 |

To calculate the required cylinder head gasket thickness, measure each piston at two locations and then calculate the average to determine piston protrusion. The larger of the three values will indicate which gasket size to use for that cylinder head.

NOTE: The difference between the minimum and maximum piston protrusions in any row must not exceed 0.1 mm. It is allowed to use gaskets of different sizes for the cylinder heads of the right and left rows.

Camshafts

The camshafts are of steel hollow tubular construction and the cams are pressed using powder metallurgy technology. Each camshaft is held in place by aluminum alloy caps: five caps are used for the exhaust shafts and four caps for the intake. On the upper side of the roof k for each bank of cylinders there is a marking: from A to I for the intake camshaft and from R to Z for the exhaust camshaft.

The left-hand exhaust camshaft has been machined to fit the rear camshaft sprocket. The rear camshaft sprocket, through a short-toothed belt and tensioner, drives the high-pressure fuel pump, located centrally behind the V-shaped row.

The exhaust camshaft of the right cylinder head is machined at the rear to connect the vacuum pump drive.

NOTE: The camshaft sprockets also form thrust surfaces to limit shaft end play. The axial play of the new shaft is from 0.065 mm to 0.185 mm. If during repair it is found that the axial play of the shaft is outside the specified limits, it may be necessary to replace the camshaft (shafts) or heads (heads) cylinders.

Timing

| Valve | Position |

| Inlet valve opening | 8.5°before TDC |

| Inlet valve closing | 35.5°after BDC |

| Exhaust valve opening | 64°before BDC |

| Closing the exhaust valve | 12°after TDC |

Inlet and outlet valves

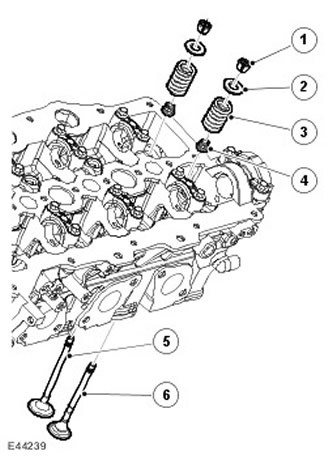

| Item name | Spare part number | Description |

| 1 | - | Valve spring bushings |

| 2 | - | Valve spring plate |

| 3 | - | valve spring |

| 4 | - | Valve stem seal |

| 5 | - | Inlet valve |

| 6 | - | Exhaust valve |

Each cylinder head has 2 overhead camshafts driving 4 valves per cylinder via steel roller arms with hydraulic lash adjusters.

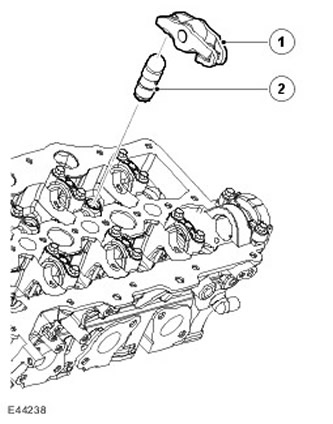

| Item name | Spare part number | Description |

| 1 | - | roller lever |

| 2 | - | Hydraulic gap compensator |

Lightweight valve train ensures low fuel consumption and low noise levels. Valve head diameters are 31mm (1.220 inches) inlet and 35 mm (1.378 inches) on release. All valve stems have a diameter of 5 mm (0.197 inch), and are supported by guide bushings and seats made from sintered metal powders. In both intake and exhaust valves, single valve springs are held in place by bushings, valve discs, and spring seats. The valve stem seals are built into the spring seats.

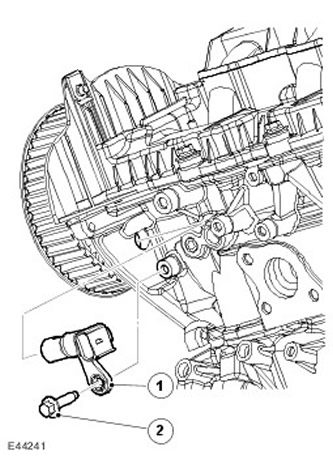

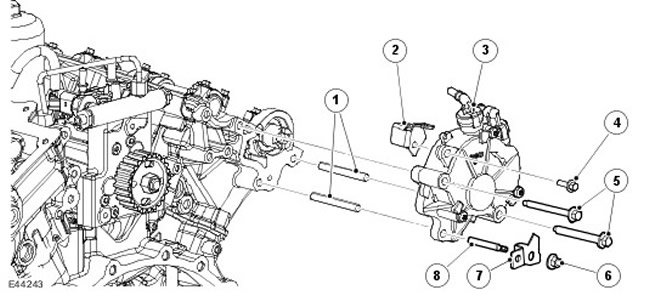

Vacuum pump

| Item name | Spare part number | Description |

| 1 | - | Position pins |

| 2 | - | bracket |

| 3 | - | Vacuum pump |

| 4 | - | Bolt |

| 5 | - | bolts |

| 6 | - | screw |

| 7 | - | bracket (transmission breather hose) |

| 8 | - | Hairpin |

The vacuum pump is located at the rear of the right bank cylinder head and is driven by the exhaust camshaft.

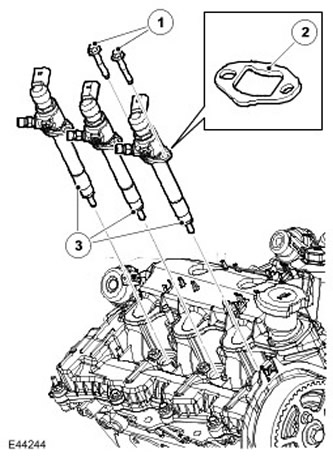

Fuel injectors

| Item name | Spare part number | Description |

| 1 | - | Bolt, 2 pcs. for each nozzle |

| 2 | - | clamp |

| 3 | - | nozzles |

Fuel injectors inject the required amount of fuel in accordance with the current engine load into the combustion chambers. In each operating cycle, fuel injection is carried out in two stages: first, a noise-reducing pilot injection is performed, and then the main injection.

The fuel rails are equipped with 6 fuel injectors with lateral fuel supply and piezoelectric control. The start of injection and the amount of injected fuel is controlled directly by the ECM. The attachment points of the nozzles to the pipeline are sealed with 2 O-rings. For more information refer to Electronic Engine Controls (303-14C Electronic Engine Controls - 2.7L Diesel). For more information refer to Fuel Charging and Controls (303-04C Fuel Charging and Controls - 2.7L Diesel).

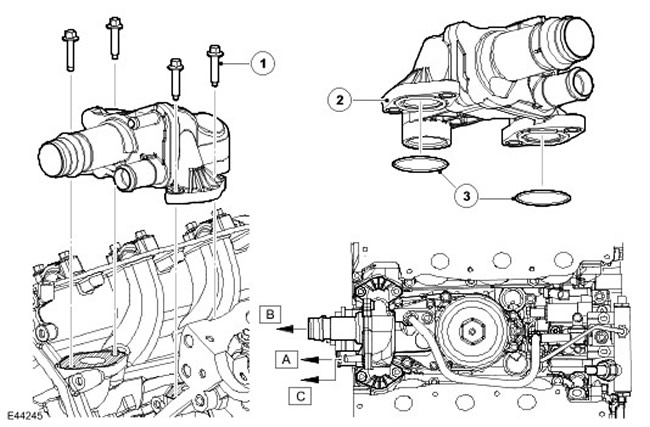

Water outlet assembly

| Item name | Spare part number | Description |

| 1 | - | Bolt, 4 pcs. |

| 2 | - | Water outlet assembly |

| 3 | - | Seals |

| A | - | Outlet housing assembly, EGR outlet |

| B | - | Outlet Housing Assembly, Radiator Outlet |

| C | - | Outlet body assembly, outlet valve |

The bleeder assembly connects the cylinder block cooling passages to the right and left cylinder head cooling passages and allows the EGR system coolant to drain and return.

Comments on this article