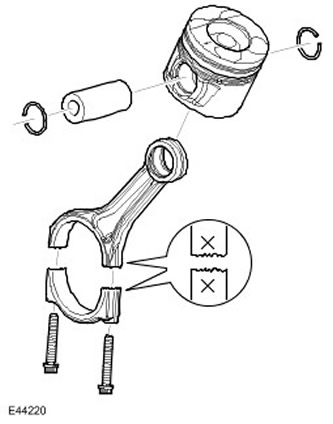

The connecting rods are made of sintered and forged steel and have split bearing caps. Bearing caps are made by breaking the connecting rod along the horizontal axis of the bearing. In addition to simplifying fabrication, when reassembling, the fracture surfaces interlock to form a seamless, strong connection. The position of the cylinder is marked on the mating surfaces to identify the matching of the connecting rods and the roof to the bearings. The selected connecting rod bearings are aluminum/tin split plain bearings. The connecting rod bearing has a special coating that allows the bearing to withstand heavy loads and increases its service life.

NOTE: Connecting rods are not selectable.

Connecting rod installation

| Item name | Spare part number | Description |

| 1 | - | Piston with connecting rod assembly, cylinders 4-6 |

| 2 | - | Piston with connecting rod assembly, cylinders 1-3 |

| 3 | - | bolts |

| 4 | - | Connecting rod bearing cap |

| 5 | - | Connecting rod lower bearing |

When installing the connecting rod, make sure the back of the connecting rod faces the center of the V-shaped cylinders.

The pistons are made of aluminum alloy and equipped with three rings. The piston head has a pronounced recess. This creates a combustion chamber that promotes swirl and turbulence, which is necessary for complete combustion of the air-fuel mixture and reduced emissions. In addition, the piston skirt has a molybdenum coating to prevent galling of the cylinder bore and piston surfaces.

The piston head has a double undulating gallery to improve piston cooling. Oil is supplied to the pistons through nozzles located in the oil line of the cylinder block. These nozzles provide optimal cooling of the pistons to reduce the temperature that rises during combustion of the mixture.

Each piston is mounted on a piston pin mounted in an aluminum/tin rod bushing.

Pistons installation

When installing the pistons, make sure that all arrows and on the piston heads are directed to the front side of the engine, and the pistons themselves are located in the corresponding rows of cylinders, i.e. in cylinders 1, 2, 3 or 4, 5, 6.

NOTE: In all engines, all pistons have the same dimensions and part numbers.

The top piston ring is tapered and tapers towards the piston crown. All rings marked 'top' must be installed with the 'top' marked on top. All rings must be evenly spaced around the piston before installation. The double beveled wiper ring gap must be on the side opposite the helical seam.

Comments on this article