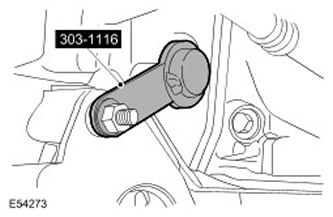

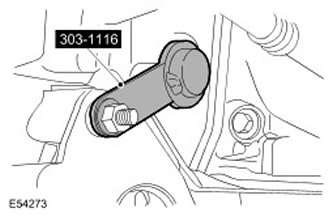

Special tool

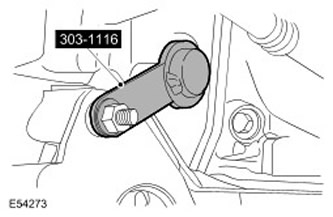

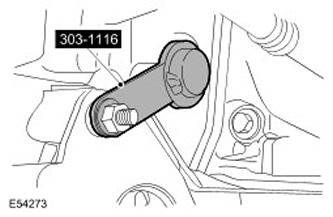

Injection timing rod - automatic transmission 303-1117 Injection timing rod - automatic transmission 303-1117 |  Injection timing rod - manual transmission 303-1116 Injection timing rod - manual transmission 303-1116 |  Device for fixing the camshaft pulley 303-1145/1 Device for fixing the camshaft pulley 303-1145/1 |

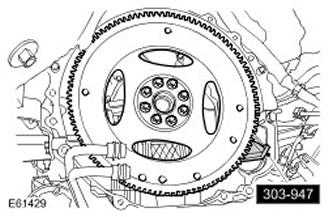

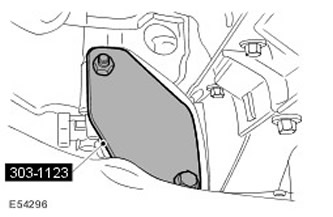

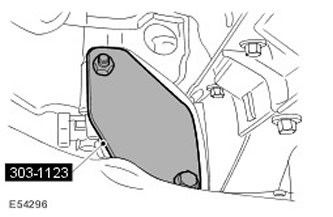

Holder - front camshaft pulley 303-1124 Holder - front camshaft pulley 303-1124 |  Tool for locking faceplate 303-947 Tool for locking faceplate 303-947 |  Flywheel locking device 303-1123 Flywheel locking device 303-1123 |

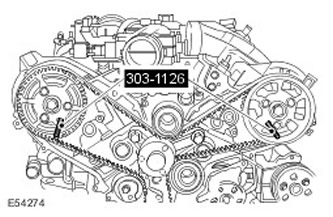

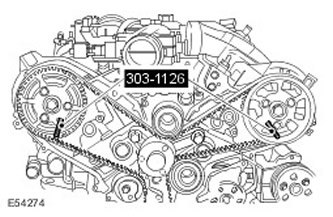

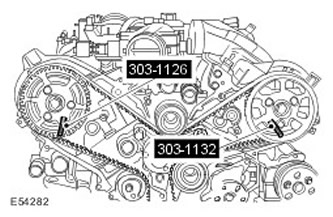

Injection timing rod - camshaft pulley 303-1126 Injection timing rod - camshaft pulley 303-1126 |

Assembly

1.

NOTE: Clean the mating surfaces of the elements.

NOTE: The oil pan extension must be bolted to the crankshaft main bearing housing within 20 minutes of applying the sealant.

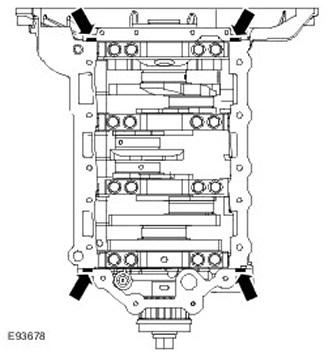

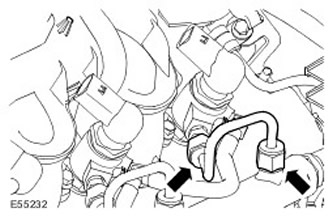

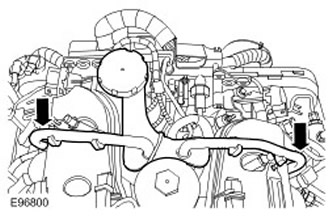

Apply a bead of sealant with a diameter of 8 mm to the shown areas of the cylinder block. Use sealant WSS-M4G323-A4-RTV.

2.

NOTE: Clean the mating surfaces of the elements.

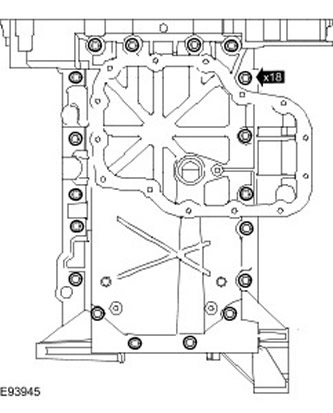

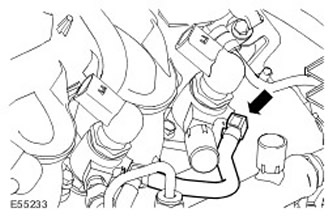

Install the oil pan extension.

- Install a new gasket.

- Screw in the bolts, but do not tighten them.

3.

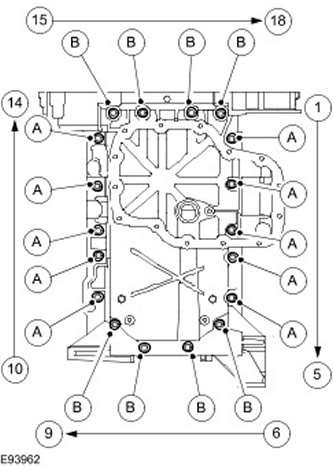

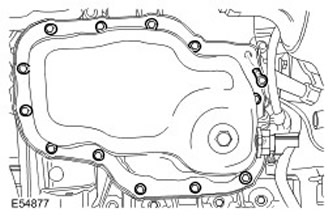

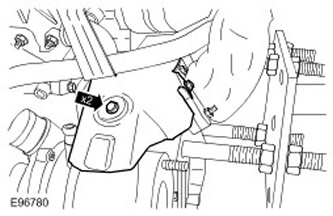

CAUTION: Tighten the bolts in 2 steps in the sequence shown.

Attach the oil pan extension.

- 1. Tighten bolts A to 10 Nm. Tighten bolts B to 4 Nm.

- 2. Tighten bolts A to 24 Nm. Tighten bolts B to 10 Nm.

4.

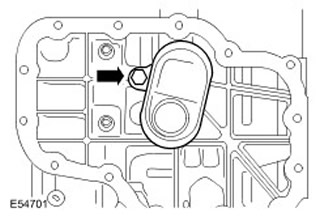

NOTE: Lubricate new seals with clean engine oil.

NOTE: Clean the elements.

Install the strainer and oil pump suction pipe.

- Clear the elements.

- Install new o-rings.

- Tighten the bolt to 10 Nm.

5.

NOTE: Clean the mating surfaces of the elements.

Install the oil pan.

- Install a new gasket.

- Tighten the bolts evenly and gradually to 10 Nm.

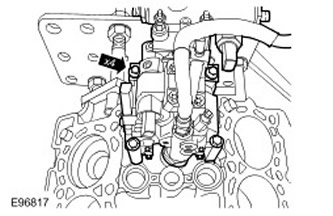

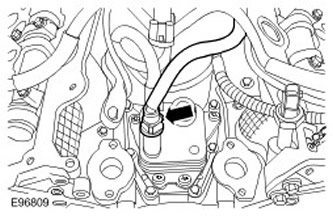

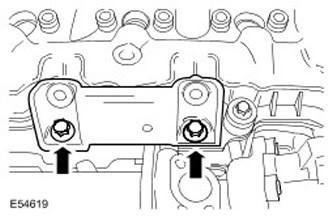

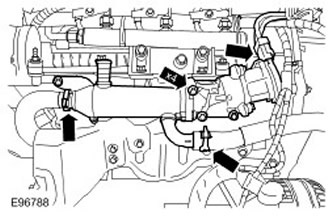

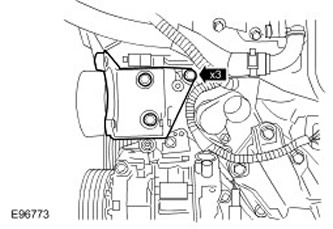

6. Install the high pressure fuel pump. Tighten the bolts to 23 Nm.

7.

CAUTION: Make sure the gasket is installed correctly.

NOTE: Clean the mating surfaces of the elements.

Install the oil cooler assembly.

- Install a new gasket.

- Install a new sealing ring.

- Tighten the bolts to 10 Nm.

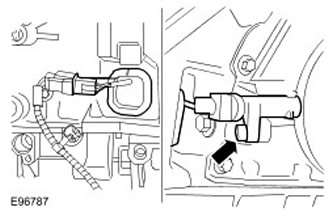

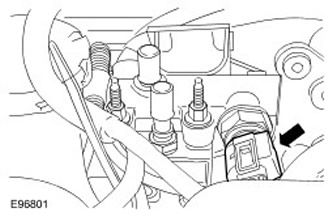

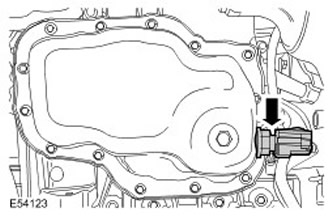

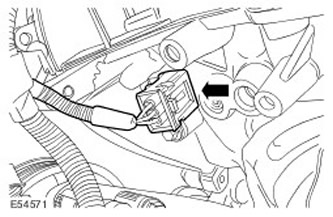

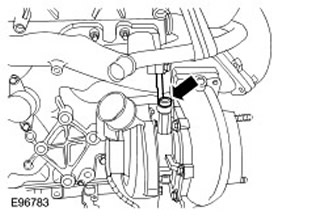

8. Install the crankshaft position sensor (CKP).

- Tighten the bolt to 5 Nm.

- Connect the electrical connector.

- Reposition the service port cover.

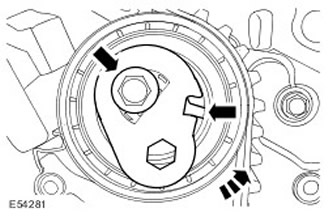

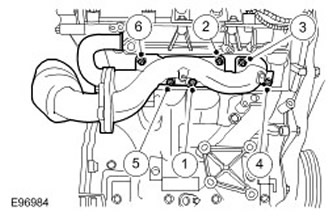

9.

CAUTION: Tighten the bolts in a criss-cross pattern.

CAUTION: Tighten the bolts in the order shown in the figure.

NOTE: Clean the mating surfaces of the elements.

Install the faceplate.

- Lock the faceplate with the special tool.

- Stage 1: Tighten the bolts to 50 Nm.

- Stage 2: Tighten the bolts 45 degrees.

- Stage 3: Tighten the bolts an additional 45 degrees.

- Remove the special tool.

10. Lock the faceplate with the special tool.

- Rotate the crankshaft clockwise to align the crankshaft adjusting hole in the flywheel or faceplate with the hole in the cylinder block.

- Screw in the starter bolt to secure the special tool.

11. Install the special tool.

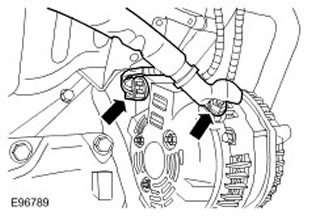

12.

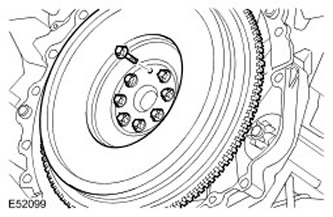

CAUTION: Tighten the bolts in a criss-cross pattern.

CAUTION: Tighten the bolts in the order shown in the figure.

NOTE: Clean the mating surfaces of the elements.

Install the flywheel.

- Stage 1: Tighten the bolts to 50 Nm.

- Stage 2: Tighten the bolts 45 degrees.

- Stage 3: Tighten the bolts an additional 45 degrees.

13.

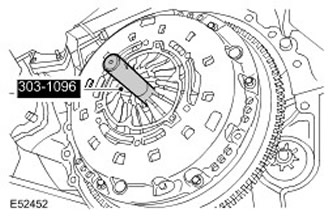

WARNING: Install the clutch disc with the markings 'TRANSMISSION SIDE' reversed (gear side) to the clutch cover.

CAUTION: Use the special tool to align the parts.

CAUTION: Tighten the bolts gradually in a criss-cross pattern.

NOTE: Clean the mating surfaces of the elements.

Using the special tool, install the clutch disc and pressure plate. Tighten the bolts to 25 Nm.

14. Remove the special tool.

15. Using the special tool, stop the flywheel.

- Rotate the crankshaft clockwise to align the crankshaft adjusting hole in the flywheel or faceplate with the hole in the cylinder block.

- Screw in the starter bolt to secure the special tool.

16. Check up a surface of the left head of cylinders on existence of deformation, measuring in the longitudinal and cross direction and on diagonals.

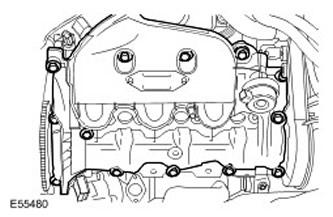

17.

NOTE: The cylinder head gasket must be installed on the cylinder block pins.

NOTE: Clean the mating surfaces of the elements.

Install a new left cylinder head gasket.

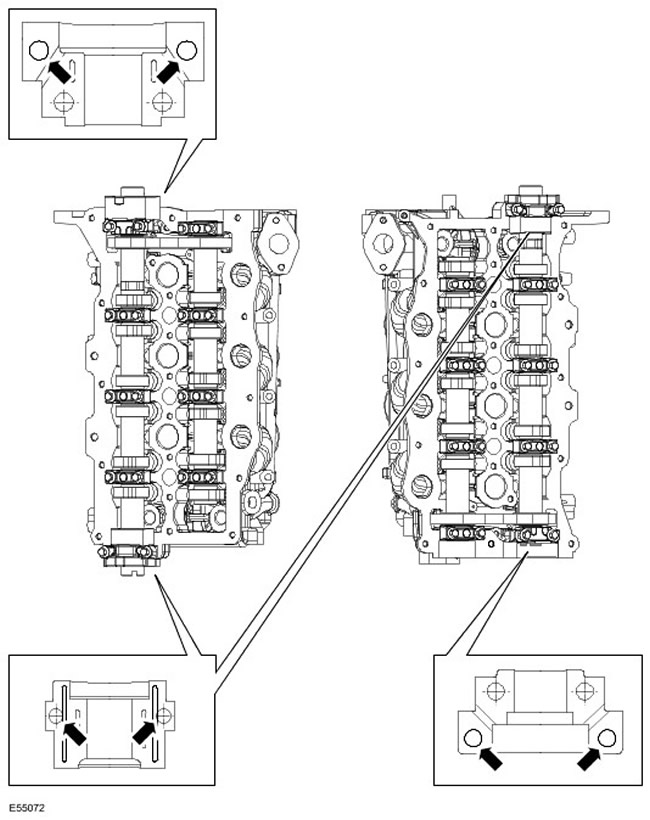

18.

CAUTION: Be careful when installing the cylinder head. Failure to follow this instruction may result in damage to the cylinder block, cylinder head or cylinder head gasket.

CAUTION: Use new bolts.

NOTE: The cylinder head gasket must be installed on the cylinder block pins.

NOTE: Make sure the cylinder head is in its original position.

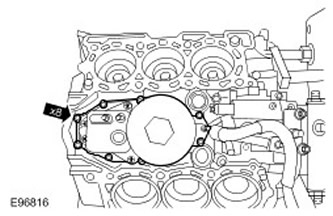

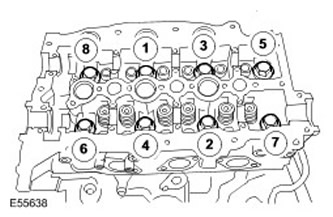

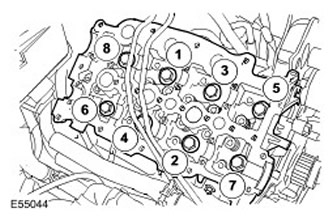

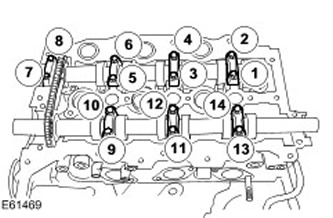

NOTE: Tighten the bolts in 4 steps in the sequence shown.

NOTE: Clean the mating surface of the element.

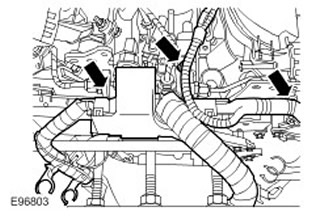

Install the left cylinder head assembly.

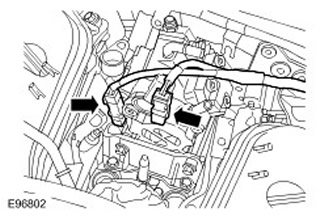

- Stage 1: Tighten the bolts to 20 Nm.

- Stage 2: Tighten the bolts to 40 Nm.

- Stage 3: Tighten the bolts to 80 Nm.

- Step 4: Tighten the bolts another 180 degrees.

19. Check up a surface of the right head of cylinders on existence of deformation, measuring in the longitudinal and cross direction and on diagonals.

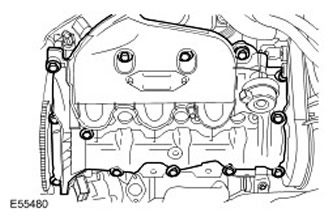

20.

NOTE: The cylinder head gasket must be installed on the cylinder block pins.

NOTE: Clean the mating surfaces of the elements.

Install a new right cylinder head gasket.

21.

CAUTION: Be careful when installing the cylinder head. Failure to follow this instruction may result in damage to the cylinder block, cylinder head or cylinder head gasket.

CAUTION: Use new bolts.

NOTE: The cylinder head gasket must be installed on the cylinder block pins.

NOTE: Make sure the cylinder head is in its original position.

NOTE: Tighten the bolts in the sequence shown in four steps.

Establish a head of cylinders of the right number in gathering.

- Stage 1: Tighten to 20 Nm.

- Stage 2: Tighten to 40 Nm.

- Stage 3: Tighten to 80 Nm.

- Stage 4: Tighten another 180 degrees.

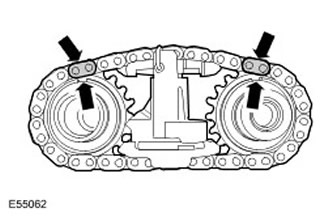

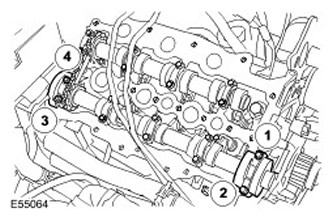

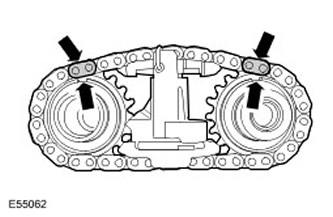

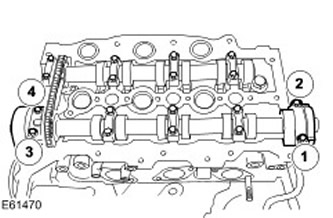

22. Install the secondary timing chain on the camshafts of the right row of cylinders.

23.

CAUTION: Do not release the pin securing the secondary timing chain tensioner until all camshaft bearing caps have been installed.

Install the right bank secondary timing chain tensioner. Align the marks on the camshafts with the marks on the secondary timing chain.

24.

NOTE: Clean the elements.

NOTE: Install a new seal.

Install the camshafts of the right row of cylinders, complete with the secondary timing chain tensioner. Lubricate the necks and cams of the camshafts.

25. Install the right-hand cylinder bank secondary timing chain tensioner. Tighten the bolts to 10 Nm.

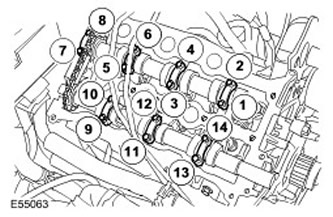

26.

CAUTION: Tighten the bolts evenly in 3 steps in the sequence shown.

NOTE: Do not install the exhaust camshaft two end bearing caps at this stage yet.

NOTE: Clean the mating surfaces of the elements.

Establish covers of bearings of camshafts of the right number of cylinders.

- Stage 1: Tighten to 1 Nm.

- Stage 2: Tighten to 5 Nm.

- Stage 3: Tighten to 10 Nm.

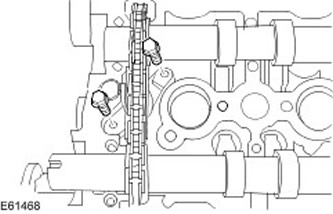

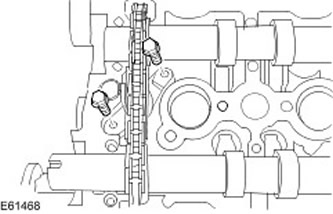

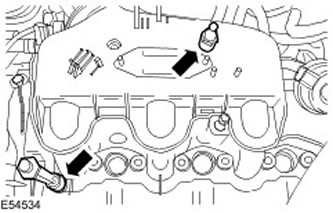

27. Apply sealant to the right exhaust camshaft end bearing cap as shown.

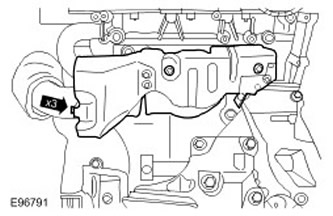

28.

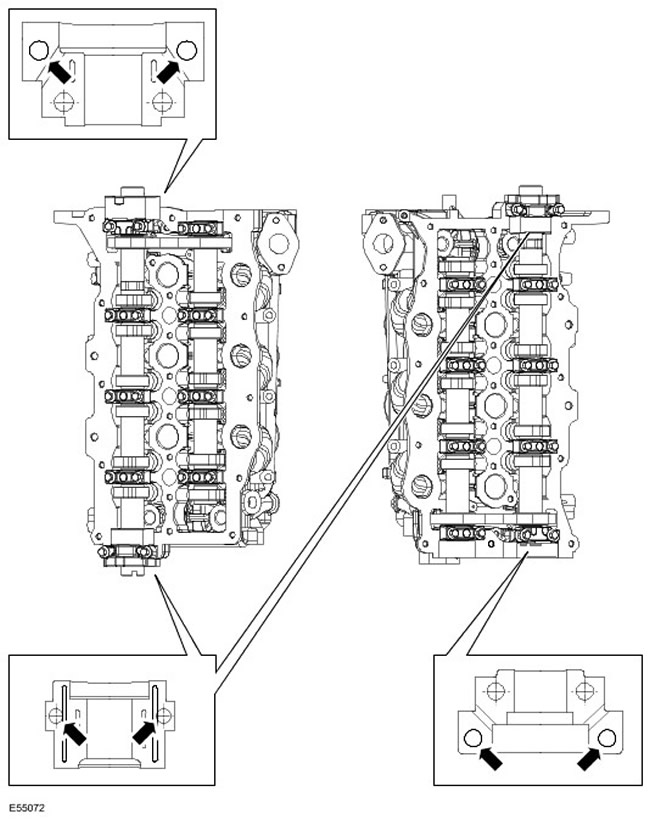

CAUTION: Tighten the bolts in the sequence shown

NOTE: Clean the mating surfaces of the elements.

Install the right side exhaust camshaft end bearing caps.

- Stage 1: Tighten to 1 Nm.

- Stage 2: Tighten to 5 Nm.

- Stage 3: Tighten to 10 Nm.

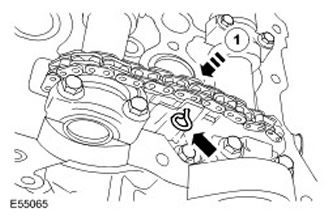

29. Release the piston of the tensioner of the secondary chain of the timing chain of the right row of cylinders. Remove lock pin.

30. Install the secondary timing chain on the camshafts of the left bank of cylinders.

31.

CAUTION: Do not release the pin securing the secondary timing chain tensioner until all camshaft bearing caps have been installed.

Install the left side timing chain tensioner. Align the marks on the camshafts with the marks on the secondary timing chain.

32.

NOTE: Clean the elements.

NOTE: Install new seals.

Install the left-hand camshafts with the secondary timing chain tensioner. Lubricate the necks and cams of the camshafts.

33. Fasten the tensioner of the secondary timing chain of the left cylinder bank. Tighten the bolts to 10 Nm.

34.

CAUTION: Tighten the bolts evenly in 3 steps in the sequence shown.

NOTE: Do not install the exhaust camshaft two end bearing caps at this stage yet.

NOTE: Clean the mating surfaces of the elements.

Establish covers of bearings of camshafts of the left number of cylinders.

- Stage 1: Tighten to 1 Nm.

- Stage 2: Tighten to 5 Nm.

- Stage 3: Tighten to 10 Nm.

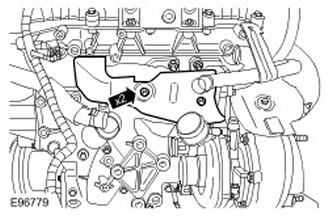

35. Apply sealant to the 2 end bearing caps of the left exhaust camshaft as shown.

36.

CAUTION: Tighten the bolts in the sequence shown.

NOTE: Clean the mating surfaces of the elements.

Establish covers of trailer bearings of a final camshaft of the left number of cylinders.

- Stage 1: Tighten the bolt to 1 Nm.

- Stage 2: Tighten the bolt to 5 Nm.

- Stage 3: Tighten the bolt to 10 Nm.

37. Release the piston of the tensioner of the secondary timing chain of the left cylinder bank. Remove lock pin.

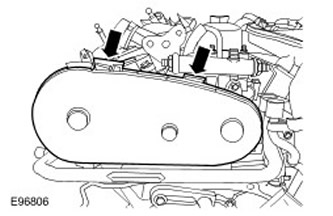

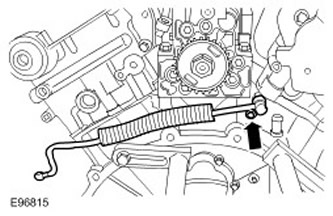

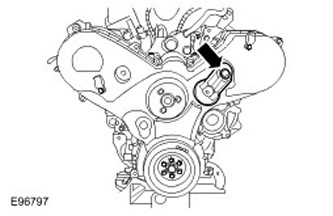

38. Install the high pressure fuel pump drive belt rear cover. Tighten the bolts to 10 Nm.

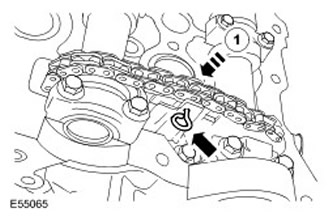

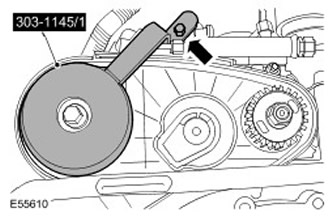

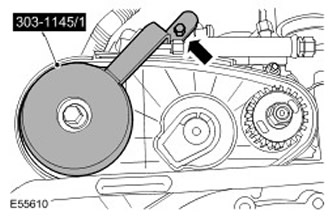

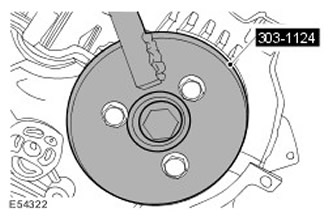

39. Install the rear camshaft pulley. Install a new camshaft pulley bolt.

40. Install the special tool on the rear camshaft pulley. Screw in and tighten the bolt.

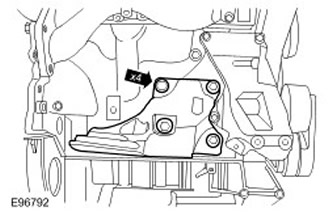

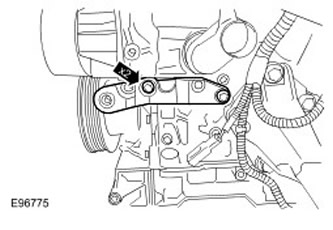

41.

CAUTION: Tighten the bolts in the order shown in the figure.

Attach the rear camshaft pulley.

- Stage 1: Tighten the bolt to 40 Nm.

- Stage 2: Tighten the bolt to 75 Nm.

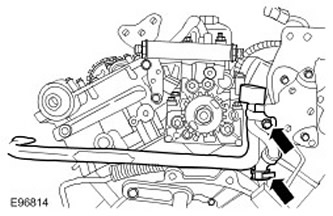

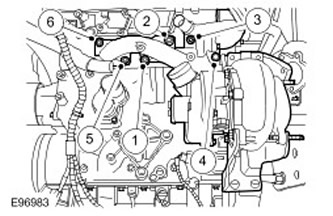

43.

CAUTION: Do not install a new injection pump belt on the pulleys with the tensioner installed. Failure to follow this instruction may result in damage to the fuel pump belt.

NOTE: The high pressure fuel pump rotates counterclockwise when viewed from the rear of the engine.

Install a new high pressure fuel pump belt.

44.

CAUTION: Do not remove the injection pump belt tensioner lock pin until the tensioner is fully installed.

CAUTION: Make sure that the high pressure fuel pump drive belt tensioner tab is correctly positioned in relation to the back cover of this belt. Failure to follow this instruction may result in engine damage.

Install a new high pressure fuel pump belt tensioner.

- Insert the tab on the new injection pump belt tensioner into the injection pump rear cover.

- Tighten the bolt to 25 Nm.

- Remove the high pressure fuel pump drive belt tensioner lock pin and discard it.

45. Install the high pressure fuel pump drive belt cover.

46. Install the cooling fan drive hub bearing. Tighten the bolts to 90 Nm.

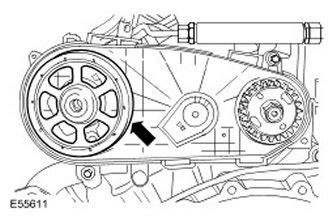

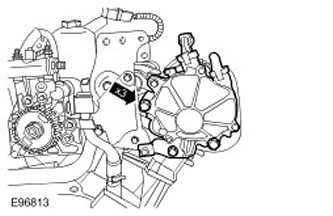

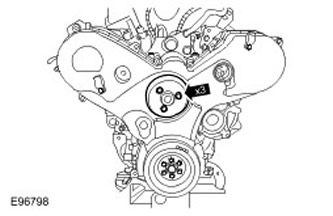

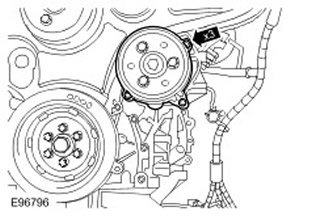

47.

CAUTION: Use new bolts.

NOTE: Left side shown, right side similar.

NOTE: Clean the mating surfaces of the elements.

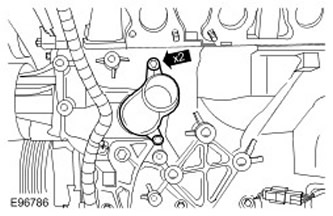

Using the special tool, install the 2 camshaft pulley hubs.

- Stage 1: Tighten to 80 Nm.

- Stage 2: Tighten another 90 degrees.

48. Install 2 exhaust camshaft pulleys. Screw in the bolts, but do not tighten them all the way yet.

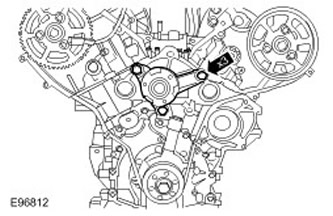

49. Install special tools. Check camshafts.

50. Install 2 intermediate timing belt pulleys.

- Install the plastic shield behind the upper intermediate pulley.

- Tighten the bolts to 45 Nm.

51. Turn both camshaft pulleys clockwise.

52. Install a new timing belt tensioner. Install the new bolt, but do not fully tighten it yet.

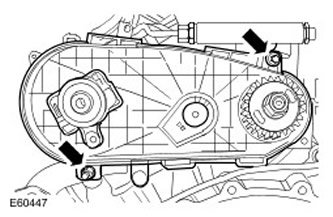

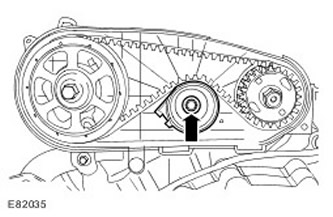

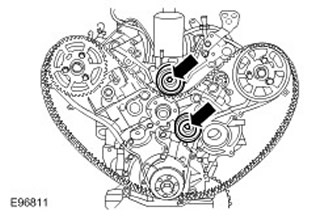

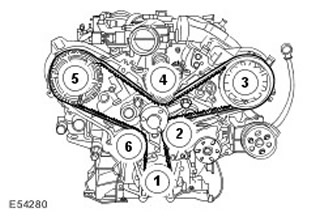

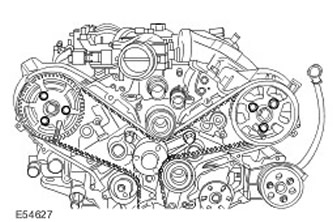

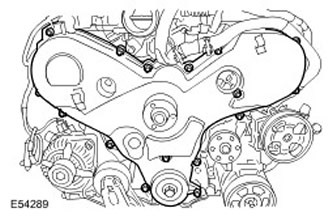

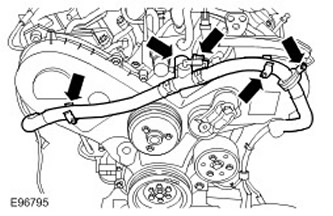

53.

CAUTION: The camshaft pulleys must remain in the position obtained by turning them clockwise.

Install a new timing belt.

- Starting at the crankshaft pulley, install the timing belt in a counterclockwise direction in the sequence shown.

- Stage 1: Put the timing belt on the crankshaft pulley.

- Stage 2: Put the timing belt on the idler pulley.

- Stage 3: Put the timing belt on the left camshaft pulley.

- Stage 4: Put the timing belt on the intermediate pulley.

- Stage 5: Put the timing belt on the right camshaft pulley.

- Step 6: Attach the timing belt to the tensioner.

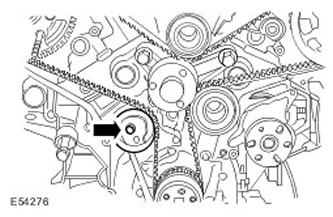

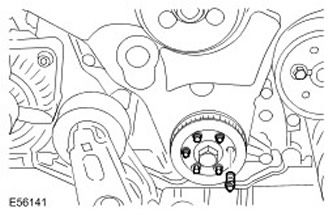

54.

CAUTION: Make sure the timing belt tensioner window is aligned with the groove.

Tension the timing belt.

- Turn the tensioner assembly counterclockwise.

- Tighten the bolt to 24 Nm.

55.

CAUTION: Do not use special tools to lock the camshafts. Failure to do so may result in damage to the engine or special tools.

Attach the camshaft pulleys.

- Using a suitable tool, hold the center bolts of the camshaft pulleys.

- Tighten the bolts to 23 Nm.

56. Remove special tools.

57. Remove the special tool. Turn out a bolt.

58. Remove the special tool. Turn out a bolt.

59. Rotate the engine two full turns clockwise.

60. Block the faceplate with the special tool. Screw in the starter bolt to secure the special tool.

61. Lock the flywheel using the special tool. Screw in the starter bolt to secure the special tool.

62. Install the special tools on the exhaust camshaft pulleys.

- If the special tool is not installed correctly, repeat the timing belt installation procedure.

- Remove the special tools from the camshaft pulleys.

63. Remove the special tool. Turn out a bolt.

64. Remove the special tool. Turn out a bolt.

65.

NOTE: Remove and discard plugs.

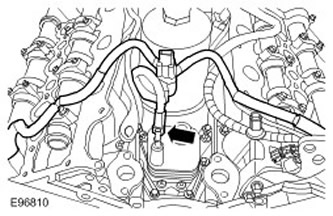

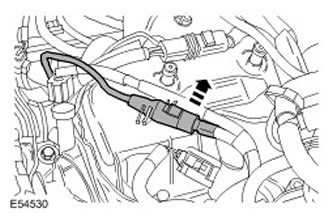

Install a new fuel injector return line.

66.

NOTE: Remove and discard plugs.

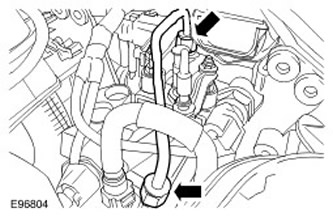

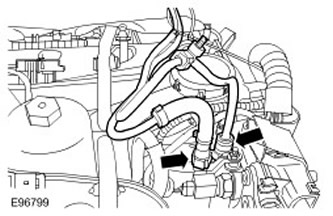

Connect the fuel line to the fuel cooler.

67.

NOTE: Install new o-rings.

NOTE: Clean the mating surfaces of the elements.

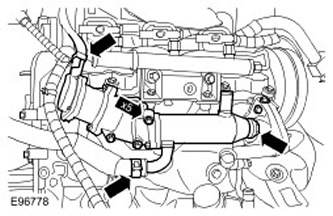

Install the cylinder head coolant outlet assembly. Tighten the bolts to 10 Nm.

68.

NOTE: Install new o-rings.

Install the turbocharger oil supply line. Tighten the bolts to 10 Nm.

69. Install ventilation piping.

- Fasten the clamp.

- Tighten the bolt to 10 Nm.

70.

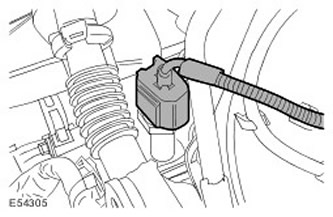

NOTE: Clean the mating surfaces of the elements.

NOTE: Install a new gasket.

Install the brake vacuum pump.

- Install the bracket.

- Tighten the bolts to 23 Nm.

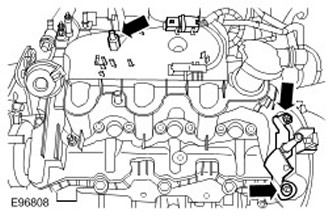

71.

NOTE: Clean the mating surfaces of the elements.

NOTE: Install a new gasket.

Install the right valve cover.

- Tighten the bolts to 10 Nm.

- Attach the glow plug electrical connector to the valve cover.

- Reattach the knock sensor electrical connector (KS) on the valve cover.

72. Screw in the mounting studs of the right engine cover.

- Install the bracket.

- Tighten the nut to 10 Nm.

- Tighten the bolt to 10 Nm.

73.

NOTE: Clean the mating surfaces of the elements.

NOTE: Install a new gasket.

Install the left valve cover.

- Tighten the bolts to 10 Nm.

- Attach the KS electrical connector to the valve cover.

74. Screw in the mounting studs of the left engine cover.

75. Install the fuel manifold brackets. Tighten the bolts to 23 Nm.

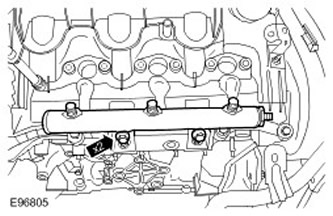

76. Install the fuel manifolds. Screw in the bolts, but do not tighten them all the way yet.

77.

NOTE: Remove and discard plugs.

Install a new high pressure fuel supply line to the right fuel rail.

- Tighten the fuel injection manifold mounting bolts to 23 Nm.

- Stage 1: Tighten the high pressure fuel supply pipe fitting on the side of the intermediate fuel manifold to 15 Nm.

- Stage 2: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 15 Nm.

- Stage 3: Tighten the high pressure fuel supply pipe fitting on the side of the intermediate fuel manifold to 30 Nm.

- Stage 4: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 30 Nm.

- Fasten the clamp.

NOTE: Remove and discard plugs.

Install a new high pressure fuel supply line to the left fuel rail.

- Tighten the fuel injection manifold mounting bolts to 23 Nm.

- Stage 1: Tighten the high pressure fuel supply pipe fitting on the side of the intermediate fuel manifold to 15 Nm.

- Stage 3: Tighten the high pressure fuel supply pipe fitting on the side of the intermediate fuel manifold to 30 Nm.

- Stage 2: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 15 Nm.

- Stage 4: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 30 Nm.

- Fasten the clamp.

NOTE: Remove and discard plugs.

Install a new intermediate fuel manifold high pressure fuel feed line.

- Step 1: Tighten the high pressure fuel supply pipe fitting on the high pressure fuel pump side to 15 Nm.

- Stage 2: Tighten the high pressure fuel supply pipe fitting on the side of the intermediate fuel manifold to 15 Nm.

- Stage 3: Tighten the high pressure fuel supply pipe fitting on the high pressure fuel pump side to 30 Nm.

- Stage 4: Tighten the high pressure fuel supply pipe fitting on the side of the intermediate fuel manifold to 30 Nm.

80.

NOTE: Remove and discard plugs.

Install a new high pressure fuel supply line to the right fuel rail.

- Tighten the fuel injection manifold mounting bolts to 23 Nm.

- Step 1: Tighten the high pressure fuel supply pipe fitting on the high pressure fuel pump side to 15 Nm.

- Stage 2: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 15 Nm.

- Stage 3: Tighten the high pressure fuel supply pipe fitting on the high pressure fuel pump side to 30 Nm.

- Stage 4: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 30 Nm.

- Fasten the clamp.

NOTE: Remove and discard plugs.

Install a new high pressure fuel supply line to the left fuel rail.

- Tighten the fuel injection manifold mounting bolts to 23 Nm.

- Step 1: Tighten the high pressure fuel supply pipe fitting on the high pressure fuel pump side to 15 Nm.

- Stage 2: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 15 Nm.

- Stage 3: Tighten the high pressure fuel supply pipe fitting on the high pressure fuel pump side to 30 Nm.

- Stage 4: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 30 Nm.

- Fasten the clamp.

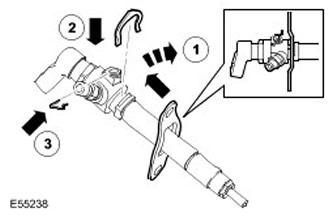

WARNING: Do not disassemble fuel injectors or clean their nozzles, even with ultrasonication. Always install new fuel injectors if necessary.

CAUTION: Do not use tools to install a new fuel return line retainer clip. Failure to do so may result in damage to the mounting clip.

Install a new fuel injector clip.

- 1. Install the fuel injector clamp spacer.

- 2. Install a new fuel return pipe clamp.

- 3. Install a new sealing washer.

83. Install the fuel injector. Tighten the bolts to 10 Nm.

84. Install the remaining fuel injectors.

85.

CAUTION: Do not allow the fittings to hit the sealing lenses of the high pressure fuel supply line, as this may damage the ends of the fuel line and allow dirt to enter the fuel injection system.

CAUTION: When fitting, apply pressure to the high pressure fuel supply line to keep the sealing lenses in contact with the fuel injector and fuel manifold cones.

NOTE: Remove and discard plugs.

Install new high pressure fuel injector feed lines.

- Stage 1: Tighten the high-pressure fuel supply pipe fitting on the injector side to 15 Nm.

- Stage 2: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 15 Nm.

- Stage 3: Tighten the high-pressure fuel supply pipe fitting on the injector side to 30 Nm.

- Stage 4: Tighten the high pressure fuel supply pipe fitting on the fuel rail side to 30 Nm.

86.

CAUTION: Make sure the fuel return line clamp is correctly installed on the fuel injector before installing the fuel return line.

Connect the fuel return line to the fuel injectors. Apply a thin coat of petroleum jelly to the O-rings on the fuel return line.

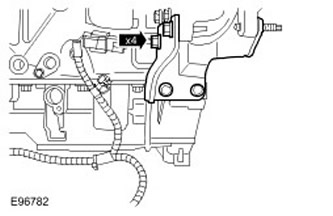

87. Install the engine wiring harness.

- Tighten the nut to 10 Nm.

- Fasten the clamps.

88. Connect the high pressure fuel pump electrical connectors.

89. Dock the fuel rail pressure sensor electrical connector (FRP).

90. Install the crankcase ventilation oil separator. Connect and secure the 2 ventilation hoses.

91. Dock the electrical connector of the fuel temperature sensor.

92.

NOTE: Left side shown, right side similar.

Connect the 2 electrical connectors KS.

93. Dock the electrical connector of the engine oil temperature sensor. Attach the wiring harness clamp.

94. Dock the camshaft position sensor electrical connector (CMP). Attach the wiring harness clamp.

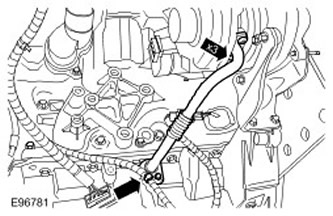

95.

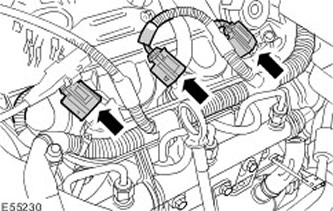

NOTE: Right side shown, left side similar.

Connect the electrical connectors of the six fuel injectors. Attach the 4 wire harness clamps.

96. Dock the electrical connector of the engine oil pressure sensor (EOP). Attach the wiring harness clamp.

97. Install 2 low pressure fuel lines.

98. Install the timing belt cover. Tighten the bolts to 10 Nm.

99. Install the crankshaft pulley. Tighten the bolts to 14 Nm.

100. Install the cooling fan pulley. Tighten the bolts to 23 Nm.

101. Install the accessory drive belt idler pulley. Tighten the bolt to 47 Nm.

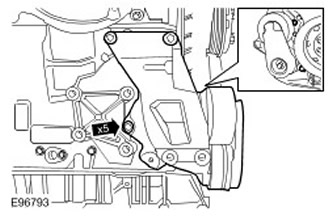

102.

NOTE: Clean the mating surfaces of the elements.

NOTE: Install a new o-ring.

Install the coolant pump. Tighten the bolts to 10 Nm.

103. Install the EGR valve coolant line (EGR).

- Screw in the bolt.

- Connect the electrical connector.

- Secure with two clips.

- Fasten the clamp.

104.

CAUTION: Use new nuts.

NOTE: Tighten the nuts in the sequence shown.

NOTE: Install a new gasket.

Install the right exhaust manifold assembly with the bypass pipe of the exhaust system. Tighten nuts to 24 Nm.

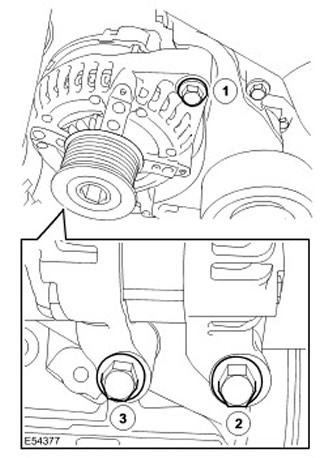

105. Install the generator bracket. Tighten the bolts to 23 Nm.

106. Establish an arm of the right support of the engine. Tighten the bolts to 110 Nm.

107. Install the right exhaust manifold heat shield. Tighten the bolts to 10 Nm.

108.

CAUTION: Tighten the bolts in the sequence shown.

Install the generator. Tighten the bolts to 47 Nm.

109. Dock the electrical connectors of the generator.

- Tighten the nut to 12 Nm.

- Move the rubber pad.

110. Install the right EGR valve and heat exchanger assembly.

- Tighten the bolts to 10 Nm.

- Connect the coolant hose and secure with a clip.

- Connect the electrical connector.

- Install and secure the new clamp.

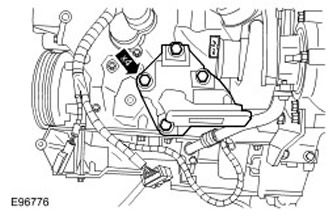

111.

NOTE: Install a new o-ring.

Install the cylinder block coolant inlet. Tighten the bolts to 10 Nm.

112.

CAUTION: Use new nuts.

NOTE: Tighten the nuts in the sequence shown.

NOTE: Install a new gasket.

Install the left exhaust manifold with turbocharger assembly. Tighten nuts to 24 Nm.

113.

CAUTION: Use new nuts.

NOTE: Install a new gasket.

Attach the bypass pipe of the exhaust system to the cool exhaust manifold. Tighten nuts to 24 Nm.

114.

NOTE: Remove and discard plugs.

NOTE: Install new sealing washers.

Connect the turbocharger oil supply line. Tighten the hollow bolt to 30 Nm.

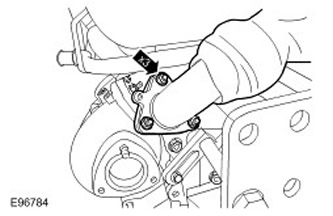

115. Install the turbocharger support bracket. Tighten the bolts to 23 Nm.

116.

NOTE: Remove and discard plugs.

NOTE: Install a new o-ring.

NOTE: Install a new gasket.

Install the turbocharger oil return line. Tighten the bolts to 10 Nm.

117. Install the turbocharger heat shield. Tighten the bolts to 10 Nm.

118. Install the left exhaust manifold heat shield. Tighten the bolts to 10 Nm.

119. NOTE: Install a new clip.

Install the EGR valve assembly with the left bank heat exchanger.

- Install the support bracket.

- Tighten the bolts to 10 Nm.

- Connect the coolant hose and secure with a clip.

- Connect the electrical connector.

- Install and secure the clamp.

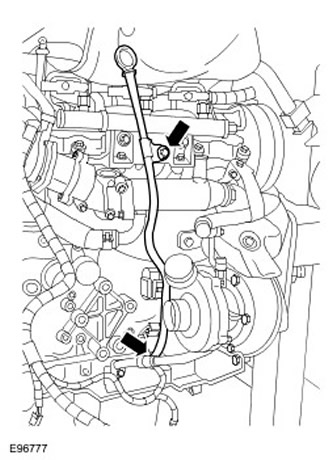

120.

NOTE: Remove and discard plugs.

NOTE: Install a new o-ring.

Install the dipstick and oil level indicator tube.

- Tighten the bolt to 10 Nm.

- Attach the wiring harness clamp.

121. Install the left engine mount bracket. Tighten the bolts to 110 Nm.

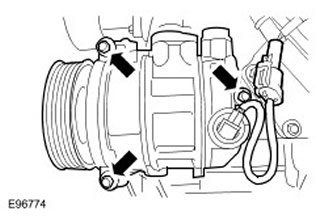

122. Install the A/C compressor bracket. Tighten the bolts to 23 Nm.

123. Install the air conditioning compressor.

- Tighten the bolts to 23 Nm.

- Connect the electrical connector.

124. Install the power steering pump bracket. Tighten the bolts to 23 Nm.

125. Remove the engine from the engine stand.

126. Install the engine. For more information, refer to Engine - Vehicle is equipped with: Automatic transmission (12.41.01.99). For more information, refer to Engine - Vehicle is equipped with: Manual transmission (12.41.01.99).

127. Fill the engine with the recommended oil to the prescribed level. For more information, refer to Draining and Refilling Engine Oil (12.60.05).

Comments on this article