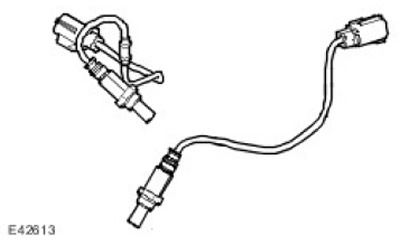

Front oxygen sensor

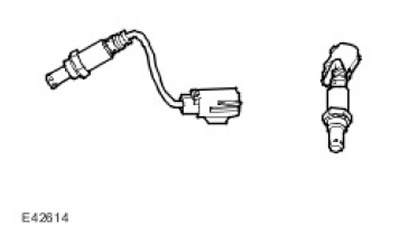

Rear oxygen sensor

There are 4 oxygen sensors in the engine exhaust system. Two front sensors (UHEGO) located in front of the catalytic converter, and the two rear (HEGO) - after the catalytic converter. The sensors measure the oxygen content in the exhaust gases. The data obtained are used to control the composition of the working mixture. The location of the sensor in the exhaust stream of each bank of cylinders allows the ECM to (the engine control unit) separately regulate the fuel supply to the cylinders of each row and more accurately maintain the composition of the working mixture, which increases the efficiency of the converter.

Proper operation of the oxygen sensors is possible only if they are heated to a high temperature. To achieve the required high temperatures, the sensors are equipped with heating elements controlled by PWM signals (pulse width modulation) , transmitted by the ECM (the engine control unit) . The heating elements begin to work immediately after starting the engine. They also operate at low loads, when the temperature of the exhaust gases is insufficient to heat the sensors. Failure of the heater leads to an increase in the duration of the period of preparation of the sensor for operation, which delays the transition to a closed control loop and increases the release of toxic substances. PWM duty cycle (pulse width modulation) - The signals are continuously monitored to prevent thermal shock of cold sensors.

UHEGO sensors (universal heated oxygen sensors) have a characteristic close to linear, and form a voltage signal of a constant value with a variable current intensity proportional to the oxygen content in the exhaust gases. This makes it possible to realize closed-loop control (with feedback) the composition of the working mixture, for example, in the engine warm-up mode (after warming up the oxygen sensor to readiness level). This allows you to more accurately control the content of toxic substances in the exhaust gases.

HEGO sensors contain a zirconium element and generate an output voltage that depends on the ratio of oxygen concentrations in the exhaust gases and the atmosphere. The sensor is a galvanic cell enclosed in a porous ceramic jacket. The voltage generated by the ceramic element depends on the oxygen diffusing through the jacket. Rated voltage at stoichiometric composition of the mixture (I =1) ranges from 300 to 500 mV. When the mixture gets richer (l<1) voltage rises to 900 mV when leaner (l>1) - drops to 0 V. The sensor tip withstands heating up to 1000 degrees Celsius for no more than 100 hours.

With an increase in vehicle mileage, the sensor ages, which increases the response time when switching from a rich mixture to a lean one and vice versa. Increased response time affects ECM closed loop operation (the engine control unit) and leads to a gradual increase in exhaust toxicity. Measurement of the response time to the transition of the composition of the mixture through the unit is used to diagnose the condition of the front sensors.

Diagnostics of the electrical circuits of the front and rear oxygen sensors is carried out continuously. Diagnostics is carried out by comparing the maximum and minimum threshold signs of open and short circuits.

Oxygen sensors require the utmost care both before and during installation. The ceramic parts of the sensor may crack if dropped, hit on the sensor, or over-torqued. The sensors should be tightened with a proven torque wrench, the tightening torque is 40-50 Nm. Protect the sensor tip from contamination with anti-seize lubricant applied to the threaded part of the sensor.

Failure modes

- Mechanical damage to the sensor and incorrect installation.

- Open circuit/sensor disconnected.

- Short circuit to power supply or «mass».

- The composition of the mixture is outside the operating range.

- Row A and B sensors crossed (reversed connectors).

- Pollution («poisoning») sensor from the use of leaded fuel or for other reasons.

- Changing the characteristics of the sensor.

- Damaged wiring harness.

- Air leak into the exhaust system.

Symptoms

- Switching by default to the control of fuel supply to the cylinders of a certain row without feedback

- High CO content.

- Strong smell of hydrogen sulfide (rotten egg smell) before switching to default mode.

- Increased release of toxic substances.

Comments on this article