Central junction box

The central junction box is used to run the power on and off programs in the ECM (the engine control unit) . When the ignition is turned on, the input of the ignition switch status sensor (pin 30 of connector C0635) 12V is applied. Then the ECM (the engine control unit) starts the power-up routines and turns on the ECM power relay (the engine control unit).

After turning off the ignition (OFF position) ECM (the engine control unit) maintains power for a few seconds (in extreme cases, if required by the cooling fans, this can continue for up to 20 minutes), performing the shutdown procedure, and then turns off the ECM power relay (the engine control unit).

Power supply

To operate the ECM (the engine control unit) a continuous supply of battery voltage is required, as well as a supply of battery supply voltage on command. Command-switched supply voltage is supplied through a relay controlled by the ECM (the engine control unit) , based on the state at the input of the central switching unit (key position 2).

Pregnant "OFF" ECM key (the engine control unit) keeps the supply voltage on until the internal self-test is completed. The main power fuse is located in the engine compartment fuse box.

Purge valve

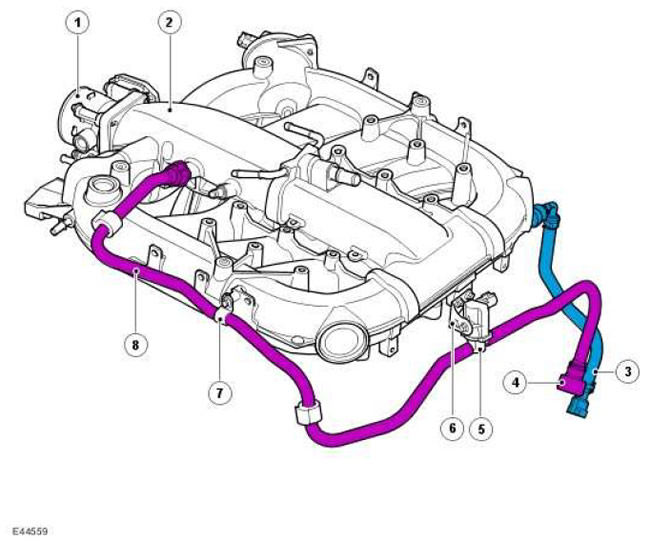

Hoses and purge valve

| Item name | Spare part number | Description |

| 1 | - | Electronic throttle |

| 2 | - | Air intake manifold |

| 3 | - | Fuel supply pipe |

| 4 | - | Purge hose fitting |

| 5 | - | Purge valve |

| 6 | - | Purge valve bracket |

| 7 | - | hose clamp |

| 8 | - | Hose connecting manifold to purge valve |

To meet the ever-increasing requirements for fuel vapors, the vehicle uses an evaporative emission system that minimizes losses from the evaporation of fuel vapors from the fuel system to the atmosphere. This is achieved by removing gases from the fuel system through a vapor trap (carbon adsorber). The charcoal acts like a sponge and traps the vapors until the canister is purged under the control of the ECM (the engine control unit).

The carbon canister is connected to the intake manifold behind the throttle body via a purge valve. The state of this valve changes according to PWM (pulse width modulation) - a signal transmitted by the ECM (the engine control unit) . The adsorber is purged by pumping clean air through the coal, which carries the hydrocarbons into the engine, where they are burned. To maintain controllability and reduce exhaust gas toxicity, the purge process must be fully controlled, since even 1% of fuel vapor from the canister into the air intake can lead to a change in the composition of the working mixture by 20%. Since the storage capacity of coal is limited, blowdown to restore its condition must be performed regularly, alternating with fuel correction, since both operations cannot be performed simultaneously.

ECM (the engine control unit) via PWM (pulse width modulation) -signal controls the purge valve, adjusting the intensity of the adsorber purge. The control of the purge process allows maintaining the stoichiometric composition of the working mixture necessary for the correct operation of the engine. In addition, due to this, the adsorber is purged quite often, thereby preventing coal saturation with fuel, leading to excessive accumulation of fuel vapors in the system (which means an increase in vapor pressure) and, as a result, to an increase in the likelihood of vapor leakage. For more information refer to Evaporative Emissions (303-13A)

Comments on this article