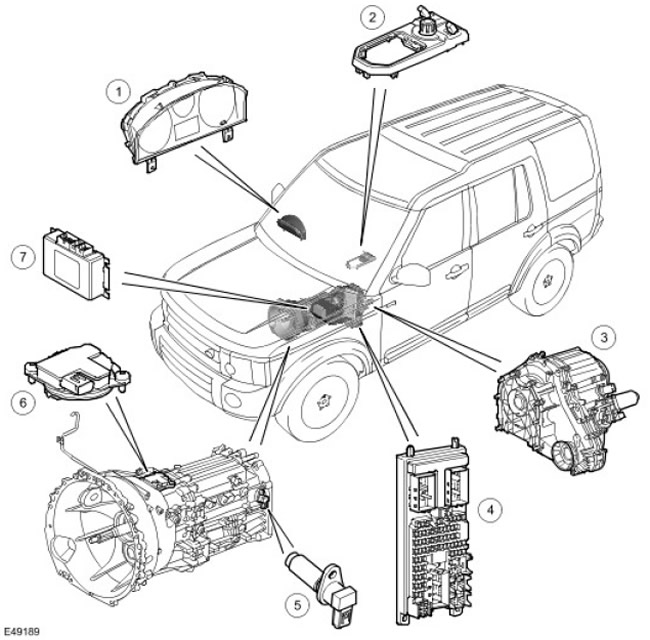

Location of transfer box components

| Item name | Spare part number | Description |

| 1 | - | Dashboard |

| 2 | - | Range select switch |

| 3 | - | Transfer case |

| 4 | - | Central distribution block (CJB) |

| 5 | - | Manual Transmission Output Shaft Speed Sensor |

| 6 | - | Gear position sensor (only for manual transmission) |

| 7 | - | Transfer case control module |

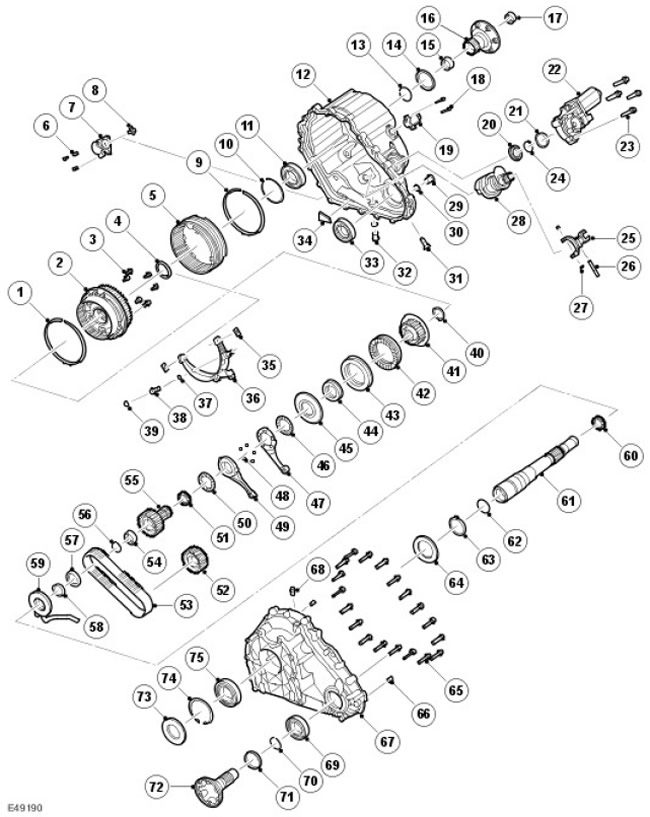

Disassembled distribution box

| Item name | Spare part number | Description |

| 1 | - | Timing spring |

| 2 | - | Differential assembly |

| 3 | - | Bolt, 6 pcs. |

| 4 | - | distance ring |

| 5 | - | Shift bushing |

| 6 | - | Bolt, 3 pcs. |

| 7 | - | Solenoid valve |

| 8 | - | Detail of the switching mechanism |

| 9 | - | Timing spring |

| 10 | - | Retaining ring |

| 11 | - | ball bearing |

| 12 | - | Rear case |

| 13 | - | Retaining ring |

| 14 | - | Sealing ring |

| 15 | - | Needle roller bearing |

| 16 | - | Rear outlet flange |

| 17 | - | Needle roller bearing |

| 18 | - | Bolt, 2 pcs. |

| 19 | - | Selector fork position sensor |

| 20 | - | Bearing |

| 21 | - | Retaining ring |

| 22 | - | Transfer case motor assembly |

| 23 | - | Bolt, 4 pcs. |

| 24 | - | Retaining ring |

| 25 | - | shift fork |

| 26 | - | fork axle |

| 27 | - | crawler |

| 28 | - | Drive assembly |

| 29 | - | Filler plug |

| 30 | - | Sealing ring |

| 31 | - | ball holder |

| 32 | - | drain plug |

| 33 | - | Sealing ring |

| 34 | - | Magnet for collecting metal chips |

| 35 | - | crawler |

| 36 | - | range fork |

| 37 | - | Sealing ring |

| 38 | - | range fork axle |

| 39 | - | Retaining ring |

| 40 | - | Retaining ring |

| 41 | - | Clutch hub |

| 42 | - | Clutch friction disc, 10 pcs. |

| 43 | - | Steel clutch disc, 10 pcs. |

| 44 | - | Disc spring, 6 pcs. |

| 45 | - | Clutch piston |

| 46 | - | Thrust Needle Roller Bearing |

| 47 | - | The lever of the electric motor of a distributing box assy |

| 48 | - | Ball, 5 pcs. |

| 49 | - | The lever of the electric motor of a distributing box assy |

| 50 | - | Thrust Needle Roller Bearing |

| 51 | - | Needle roller bearing |

| 52 | - | Front output sprocket |

| 53 | - | Chain |

| 54 | - | Needle roller bearing |

| 55 | - | Star |

| 56 | - | Retaining ring |

| 57 | - | thrust washer |

| 58 | - | distance ring |

| 59 | - | Oil pump assembly |

| 60 | - | Needle roller bearing |

| 61 | - | input shaft |

| 62 | - | Sealing ring |

| 63 | - | Retaining ring |

| 64 | - | Disc spring, 2 pcs. |

| 65 | - | Bolt, 19 pcs. |

| 66 | - | locating pin (2 pcs.) |

| 67 | - | Front crankcase |

| 68 | - | breather cartridge |

| 69 | - | Bearing |

| 70 | - | Retaining ring |

| 71 | - | Sealing ring |

| 72 | - | Front outlet flange |

| 73 | - | Sealing ring |

| 74 | - | Retaining ring |

| 75 | - | Bearing |

General information

The DD295 transfer case is a 50/50 front and rear driveshaft with permanent all-wheel drive. Transfer case manufactured by Magna Steyr Powertrain (Graz, Austria) and has the following features:

- Permanent all-wheel drive with a bevel center differential providing a 50:50 torque split.

- Range selection option (high or low) for optimizing vehicle performance on and off the road

- Two-stage, fully synchronized on-the-go range shifting system that gives the driver the ability to change ranges without stopping the vehicle

- An electronically controlled multi-plate clutch that locks the center differential and changes torque distribution to improve traction and vehicle stability.

- preload, which increases the locking torque with increasing drive torque;

- slip control that increases the locking torque in off-road conditions and reduces it to achieve the best comfort, for example when parking.

The transfer case is acted upon by the primary torque of the gearbox output shaft, which is transmitted through the gearbox to the front and rear drive shafts.

Primary torque is evenly distributed by means of a bevel differential. For optimal distribution of torque between the wheels in all road conditions, the transfer case is equipped with an electronically controlled torque lock and change device. Based on the signals received by the transfer case control module from various vehicle systems, this device determines the degree of wheel slip and, in accordance with this, blocks the differential. The locking moment is transmitted to the differential through the multi-plate clutch assembly.

The planetary kit, located in the differential assembly, allows the driver to select high or low range while driving, which is called "switching on the go". In low range, the planetary kit delivers a 2.93:1 gear ratio that allows the vehicle to travel at very low speeds off-road and when towing. The high range is directly driven by the gearbox output shaft and provides a ratio of 1:1.

Locking center differential with torque redistribution and "switching on the go" are carried out by the transfer case DC motor, which is driven by the transfer case control module using pulse width modulation signals (PWM).

Comments on this article