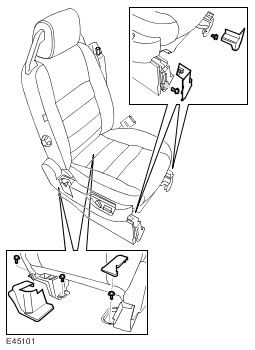

Seats and seat belts

Front seat frame fasteners - every 2 years or 48,000 km

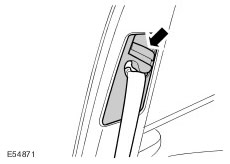

1. Carefully remove the trim panels covering the front seat frame Torx head screws.

2. Check that the front seat frame Torx head screws are securely tightened and that there are no signs of movement on the frame.

3. After completion of work, install the trim panels in place.

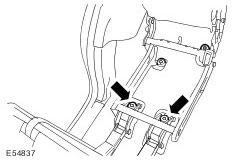

Rear Seat Frame Front Mounts - Every 2 years or 48,000 km

4. Make sure the front fasteners of the rear seat frame are securely tightened and there are no signs of movement on the frame.

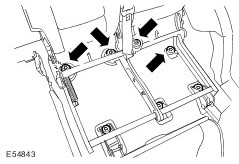

Rear Seat Frame Mounts - Every 2 years or 48,000 km

5. Fold the seat cushions forward and check that the rear seat frame rear fasteners are securely tightened and there are no signs of movement on the frame.

6. After completing the work, return the seat cushions to their original position.

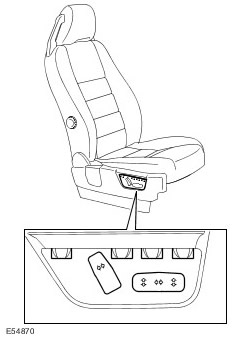

Front seat controls

7. Check the operation of all seat controls.

Seat belts - every 2 years or 48,000 km

8. Fully extend each seat belt and ensure that it is retracted by the retractable reel.

9. Check all belts along their entire length for signs of fraying or damage.

10. Fasten each belt to the appropriate buckle and make sure the tongue is securely fastened and unfastened properly.

11. Check the security of all seat belts and seat belt buckles.

12. Check the operation of the front seat belt shoulder fastening adjusters.

Lamps, horns and control lamps

1. Check the operation of the headlights, side lights, fog lights, reversing lights and tail lights.

2. Check the operation of the automatic system for correcting light beams in height (if available).

3. Check the operation of the direction indicators and alarms.

4. Check the operation of the stop lights.

5. Check the condition of all outdoor lighting fixtures. Pay special attention to the headlight and fog lamp lenses and make sure that they are not chipped or otherwise damaged.

6. Check the volume and clarity of the audio signal.

7. Turn on the headlights and check the operation of the position lamps / headlights indicator when the door is opened.

8. Check the operation of the interior lighting devices.

9. Check the operation of the block of indicators and annunciators of the instrument panel.

Windshield wipers and washers

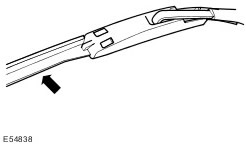

1. Check the condition of all wiper blades and make sure they are not damaged or cracked.

2. Check up reliability of fastening of levers of a screen wiper.

3. Operate the windshield and rear window washers and make sure that the jets are not clogged and are directed correctly.

4. Turn on the front and rear wipers in all modes and check that they operate smoothly.

Check high/low gear engagement

1. Select a low gear, drive the vehicle forward 34 times the body length, then stop the vehicle and select a higher gear - the gears should engage smoothly.

Fine filter

1. Replace fine filter. For more information refer to Pollen Filter (412-01 Air Distribution and Filtering)

Corrosion/cosmetic inspection

1.

Perform a corrosion/cosmetic check every year according to "Annual Corrosion Inspection Checklist".Wheels and tires

1. Check that the tires meet the manufacturer's specifications. For more information refer to Wheels and Tires (204-04 Wheels and Tires).

2. Check/adjust tire pressure, including spare wheel. For more information refer to Wheels and Tires (204-04 Wheels and Tires).

3. Vehicles with unidirectional tires: Mark the position of the wheels in relation to the hub and the location of each wheel on the vehicle so that the wheel is in the same position when installed.

4. Loosen the wheel nuts. Raise the car so that the wheels turn freely. For more information about refer to Lifting (100-02 Jacking and Lifting).

5. Remove wheels.

6. Inspect tires for cuts, bulges, or delaminations. Check the tread pattern for wear across the entire width and circumference of the tire and make sure the tread depth is in accordance with local regulations.

NOTE: Do not install wheels at this stage.

Brake system

WARNING: For heavy duty vehicles, the following maintenance operations must be carried out every 3 months or 6000 km.

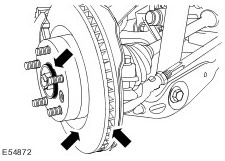

1. Check the front pad wear. For more information refer to Specifications (206-03 Front Disc Brake).

2. Check the rear pads for wear. For more information refer to Specifications (206-04 Rear Disc Brake).

3. Check for signs of brake fluid leaks from the calipers.

4. Check the condition of the brake discs.

5. Check the condition of all pipelines and hoses of the brake booster and brake system for abrasions and leaks.

6. Clean the centering shoulders of the wheel hubs and apply grease (Part No. Land Rover RYL 105020) on the seating surface of each centering shoulder on the wheel.

7. Vehicles with tires with a unidirectional tread pattern: Install the wheels on their respective hubs, making sure the wheel is in the same position with respect to the hub as it was before removal.

8. Vehicles with non-directional tires: Install the wheels on the opposite side of the vehicle, making sure they remain on the same axle.

9. Install and tighten wheel nuts (tightening torque 140 Nm).

WARNING: For heavy duty vehicles, the next maintenance operation must be carried out every 2 years or 48,000 km.

10. Every 3 years or 72,000 km: Change the brake fluid. For more information refer to Brake System Bleeding (206-00 Brake System - General Information). For more information on refer to Brake System Pressure Bleeding (206-00 Brake System - General Information).

11. Every 6 years or 144,000 km: Replace all flexible brake hoses.

Electronic parking brake

WARNING: For heavy duty vehicles, the following maintenance operations must be carried out every 3 months or 6000 km.

1. Check the electronic parking brake setting. For more information refer to Parking Brake Shoe and Lining Adjustment (206-05 Parking Brake and Actuation).

2. Heavy Duty Vehicles: Check the condition of the electronic parking brake.

Wheel speed sensors

WARNING: For heavy duty vehicles, the next maintenance operation must be carried out every 3 months or 6000 km.

1. Check the wheel speed sensor harnesses for damage.

Fuel filter element

WARNING: For heavy duty vehicles, the next maintenance operation must be carried out every 12 months or 24,000 km.

1. Every 2 years or 48,000 km: Replace the fuel filter element. For more information refer to Fuel Filter Element - VIN Range: SALLA000304->END OF 06MY (310-01C). For more information on refer to Fuel Filter Element - VIN Range: 07 MODEL YEAR->CURRENT (310-01C).

Fuel sump

WARNING: For heavy duty vehicles, the next maintenance operation must be carried out every 3 months or 6000 km.

1. Drain the fuel from the fuel sump. For more information refer to Diesel Filter Water Drain-Off (310-00).

Radiator/Intercooler and Cooling Fan

WARNING: Heavy Duty Vehicles:

1. Inspect the radiator/intercooler for external obstructions and the fan impeller for damage.

2. Remove dirt from the intercooler with a low pressure hose.

Air suspension

1. Every 5 years or 120,000 km - Heavy duty vehicles: Replace the air suspension compressor filter. For more information refer to Air Suspension Air Filter (204-05 Vehicle Dynamic Suspension).

Door locks and hinges

1. Check the operation of the locks of all doors, the hood and the fuel filler cap.

2. Lubricate all door locks, hood lock and fuel filler cap lock.

Air filter

WARNING: For heavy duty vehicles, the next maintenance operation must be carried out every 3 months or 6000 km.

1. Every 3 years or 72,000 km: Replace the air filter element. For more information refer to Air Cleaner Element (303-12 Intake Air Distribution and Filtering - 2.7L Diesel).

Suspension and body mounts

1. Make sure there is no play in all suspension and body silent blocks.

2. Check the condition of the rubber boots and suspension boots.

Fuel system

1. Check fuel system lines, hoses and connections for leaks, corrosion and friction wear.

Wiring harnesses

1. Check all wiring harnesses for friction wear.

Oil/fuel leaks

1. Check for oil/fuel leaks.

Exhaust system

1. Check the exhaust system for leaks, damage, and connections.

Power steering

1. Check up a condition of fastening of spherical joints of draft of a steering with the amplifier, protective covers, spherical joints and anthers.

2. Check power steering system piping, hoses and connections for friction wear, leaks and corrosion.

Clutch

1. Check hydraulic clutch system piping and connections for chafing, leaks and corrosion.

Lamp (lamps) malfunctions

1. If the lamp turns on (lamps) failure, check the relevant system with the T4 and report the results.

Road test

1. Carry out a road test of the vehicle. For more information refer to Road/Roller Testing (100-00 General Information).

Comments on this article