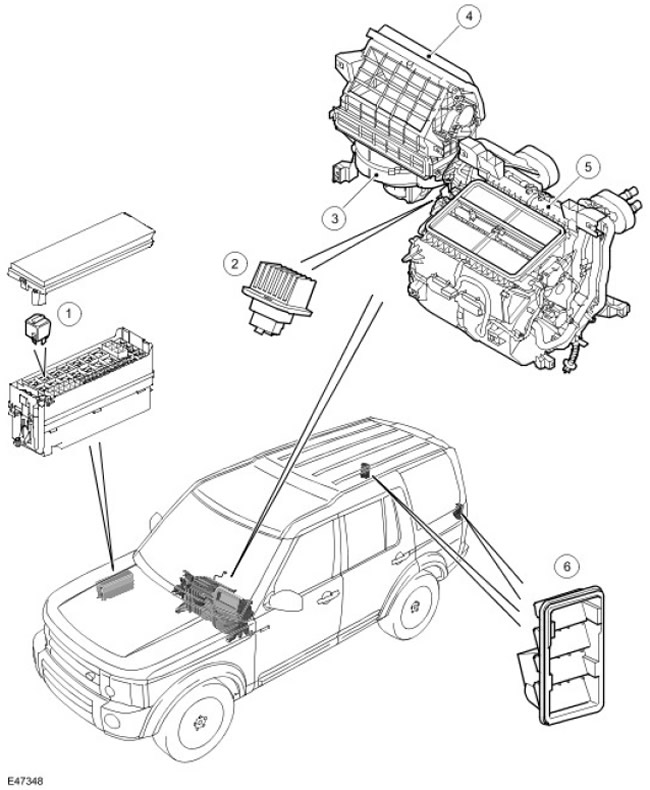

Location of elements

NOTE: The figure shows RHD (left hand drive vehicle) shown, LHD (right hand drive vehicle) has a similar device.

| Item name | Spare part number | Description |

| 1 | - | Fan relay |

| 2 | - | Fan control module |

| 3 | - | blower fan |

| 4 | - | Supply air duct |

| 5 | - | heater |

| 6 | - | Ventilation nozzles |

General information

The heating and ventilation system maintains the desired temperature and flow of air supplied to the vehicle interior. The system includes the following elements:

- Supply air duct.

- Fan.

- Fan control module.

- Fan relay.

- Heater.

- Two outlet vents.

Supply air duct

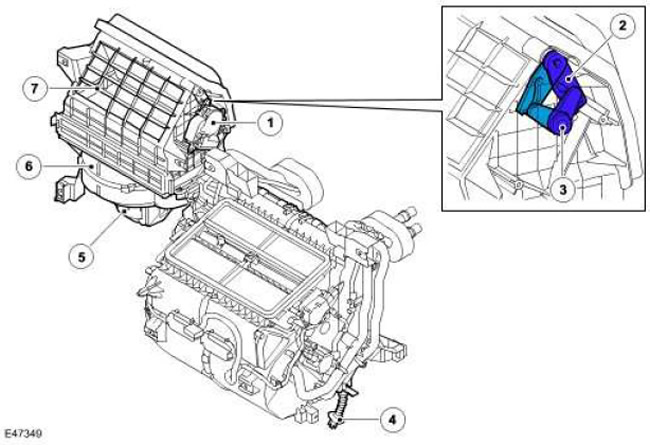

NOTE: The picture shows a car with RHD (), vehicle with LHD () mirror symmetrical.

| Item name | Spare part number | Description |

| 1 | - | Recirculation damper motor |

| 2 | - | Recirculation damper lever |

| 3 | - | Electric recirculation lever |

| 4 | - | Evaporator drain tube |

| 5 | - | blower fan |

| 6 | - | Supply air duct |

| 7 | - | Recirculation circuit inlet |

The supply air duct is located behind the control panel on the front passenger side and connects the mixing chamber located under the windshield and the heater.

The mixing chamber is formed by an upper and lower casing, as well as a molding. Fresh air enters the mixing chamber through the molding. From the mixing chamber, air enters the dehumidifier and then into the inlet pipe of the supply air duct.

The air intake duct has a grill through which recirculation air from the passenger compartment enters the intake pipe. The following components are also located in the supply air duct:

- Cabin air filter. For more information, please refer to Air Distribution and Filtering (412-01 Air Distribution and Filtering)

- Fan.

- Fan control module.

To select the source of air intake, a recirculation circuit damper is installed between the inlet pipes for the intake of fresh air and air from the passenger compartment. The lever on the recirculation damper is driven by the damper motor. The operation of the recirculation damper in automatic mode is controlled by the ATC controller (automatic temperature control), and in manual - by a switch on the control panel of the ATC controller (automatic temperature control). For more information refer to Control Components (412-04 Control Components)

Fresh or recirculated air enters the supply air duct and, after passing through the cabin air filter, enters the fan inlet. From the fan, air enters the heater through the outlet of the supply air duct. The movement of air in the supply air duct is provided by the operation of the fan and the counter pressure when the vehicle is moving.

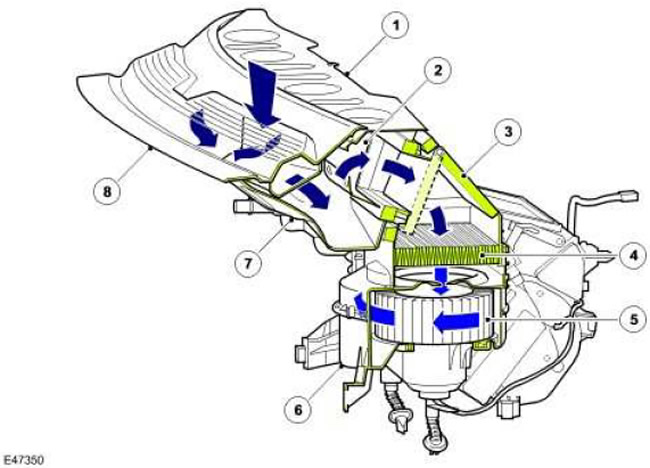

Air movement through the supply duct

| Item name | Spare part number | Description |

| 1 | - | Top casing |

| 2 | - | water separator |

| 3 | - | Recirculation damper |

| 4 | - | Cabin air filter |

| 5 | - | blower fan |

| 6 | - | Air duct cover |

| 7 | - | Bottom casing |

| 8 | - | Mixing chamber molding |

Fan

The fan is installed in the supply air duct under the cabin air filter. It is an open centrifugal type fan driven by an electric motor. The fan is controlled by the ATC controller (automatic temperature control) through the fan relay which is located in the BJB (battery junction box), and a fan control module. The fan control module is installed in the supply air duct behind the fan, the air flow of which removes the heat generated during the operation of the module. The recirculation damper motor, fan and fan control module are connected by a wiring harness on the supply air duct to a common vehicle wiring harness.

When there is a need for fan operation, the ATC controller (automatic temperature control) supplies power to the fan relay coil. Once activated, the relay supplies power from the battery to the fan motor, which is connected to "weight" through the fan control module. The fan speed is controlled by the fan control module, which changes the voltage supply to the fan motor in accordance with PWM (width modulated signal), received from the controller aTc (automatic temperature control). To change the supply voltage of the fan motor, the ATC controller (automatic temperature control) changes the duty cycle of the PWM signal (pulse width modulation).

In automatic fan mode, the ATC controller (automatic temperature control) changes the fan speed in accordance with the algorithm for maintaining comfortable conditions. In manual fan mode ATC controller (automatic temperature control) sets one of seven fixed fan speeds selected on the control panel. For more information refer to Control Components (41204 Control Components)

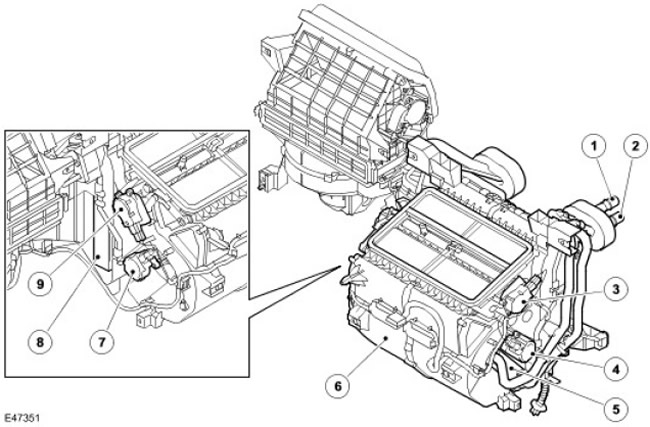

Heater

NOTE: RHD model shown (), model with LHD () has a similar device.

| Item name | Spare part number | Description |

| 1 | - | Outlet pipe of the cooling system |

| 2 | - | Coolant inlet pipe |

| 3 | - | Windscreen damper motor |

| 4 | - | RH (right) temperature controller damper motor |

| 5 | - | heater radiator |

| 6 | - | heater cover |

| 7 | - | LH (left) temperature controller damper motor (only for automatic systems) |

| 8 | Evaporator | |

| 9 | Damper motor for air distribution to the face and feet |

The heater regulates the temperature of the air supplied to the distribution ducts under the control of the ATC controller (automatic temperature control). The heater is installed in the middle of the car, between the instrument panel and the bulkhead of the engine compartment. The heater consists of a molded plastic housing containing the evaporator, heater core and control dampers. Through the internal channels built into the casing, the air passes through the casing and is divided into two streams, one is sent to the LH () nozzles, and the second - in RH () nozzles.

When the A/C system works (conditioning), the evaporator cools the air entering the heater.

The heater core heats the air supplied to the distribution ducts. The heater core is an aluminum two-way finned tube heat exchanger mounted across the heater casing. The heater radiator is connected to the engine cooling system by two aluminum tubes passing through the partition of the engine compartment. When the engine is running, the coolant pump constantly pumps coolant through the heater core. If the vehicle is equipped with a fuel coolant heater (FFBH), when the FFBH is turned on, the circulation of the liquid is enhanced by the circulation electric pump. For more information refer to Auxiliary Heater (412-02B Auxiliary Heating)

Two temperature control flaps, LH () and RH (), regulate the air flow through the heater radiator, thereby maintaining the desired air temperature at the heater outlet. In automatic systems, both dampers of the temperature controller operate independently, allowing different temperatures to be maintained on the LH () and RH () nozzles. In systems with manual control, the temperature controller dampers are connected to each other and maintain at LH () and RH () nozzles at the same temperature.

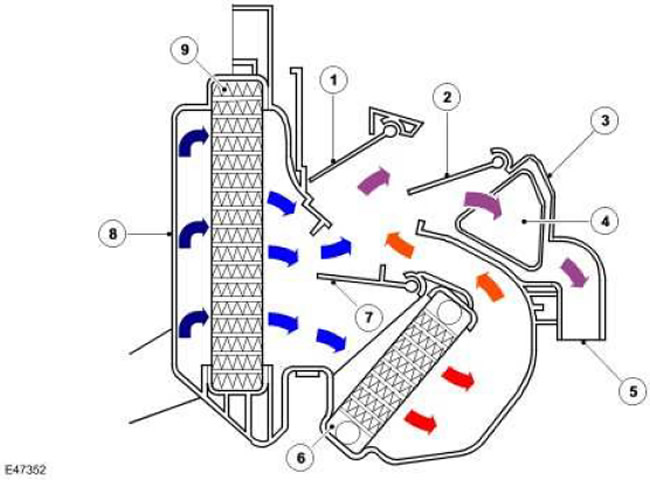

Air flow through the heater

| Item name | Spare part number | Description |

| 1 | - | Windscreen damper |

| 2 | - | Air distribution damper in the face and feet |

| 3 | - | heater cover |

| 4 | - | Front leg air nozzle |

| 5 | - | Rear leg air nozzle |

| 6 | - | heater radiator |

| 7 | - | Temperature controller damper |

| 8 | - | Air duct cover |

| 9 | - | Evaporator |

Stepper motors

In RH automatic systems () and LH () temperature controller dampers are driven by separate stepper motors. In systems with manual control RH () and LH () temperature controller dampers are driven by a single stepper motor.

Stepper motors can also actuate air distribution dampers. The first is driven by the windshield blower motor, and the second is driven by the face and foot air distribution damper motor.

When replacing a stepper motor, make sure the new component is identical to the old one. Even though stepper motors look the same on the outside, they differ in design. Therefore, installing an incorrect motor may result in damage.

The operation of the stepper motors for the air distribution dampers and temperature regulator dampers is controlled by the ATC controller (automatic temperature control), which is connected to the stepper motors via the local LIN bus.

All stepper motors are equipped with microprocessors that store position information. To ensure proper control of stepper motors with an ATC controller (automatic temperature control), you must enter the following information for each engine:

- range of movement between extreme positions,

- the position of each engine relative to the limits of the set range.

Under normal conditions, the information stored in the memory of the stepper motors and the ATC controller (automatic temperature control), matches. In this case, the ATC controller (automatic temperature control) considers that there are no problems and the system is running normally. When discrepancies are detected, the ATC controller (automatic temperature control) performs the calibration procedure.

The stepper motor calibration procedure usually takes about 15 seconds, but in some cases it can take up to 2 minutes. During this procedure:

- LED (Light-emitting diode) programmable glass defrost function, located on the front panel of the ATC module (automatic temperature control), flashes.

- All other climate control system operations are suspended.

- Switch off the ignition.

- Turn the ignition back on.

- Check if the LED is blinking () functions of programmable defrosting of glasses.

Automatic calibration: ATC controller (automatic temperature control) automatically initiates a calibration procedure every 175 hours of vehicle operation. It runs for approximately 1 minute during the first ignition off after another 175 hours have elapsed. In this case LED () programmable defrost function does not flash.

Force Calibration: You can manually initiate the ATC controller (automatic temperature control) to perform an extraordinary stepper motor calibration procedure. To do this, turn on the ignition while holding down the ECON button and the recirculation button on the ATC controller panel (automatic temperature control). ATC controller (automatic temperature control) will perform the stepper motor calibration procedure, but instead of LED () programmable defrost function, the LED will flash () ECON.

Stepper motor diagnostics

Troubleshooting procedures for stepper motors in the heater system can be divided into two main groups:

- Electrical System Faults DTC Set (diagnostic trouble code) and stored in the memory of the ATC controller (automatic temperature control).

- Mechanical system failure Programmable LED () programmable defrost function will flash to alert the driver that the ATC controller (automatic temperature control) tries to perform the calibration procedure.

- replacement of one or more stepper motors

- ATC controller replacement (automatic temperature control)

- entry into the system of a foreign object, which led to the seizure of the electric motor

Ventilation nozzles

Ventilation nozzles provide a free flow of air through the vehicle interior. Nozzles mounted on LH () and RH () rear side panels of the body behind the rear position lamps.

The ventilation nozzles consist of a grid closed with a soft rubber damper, which acts as a non-return valve. The rubber damper automatically takes the desired position depending on the pressure difference in the passenger compartment and outside.

Comments on this article