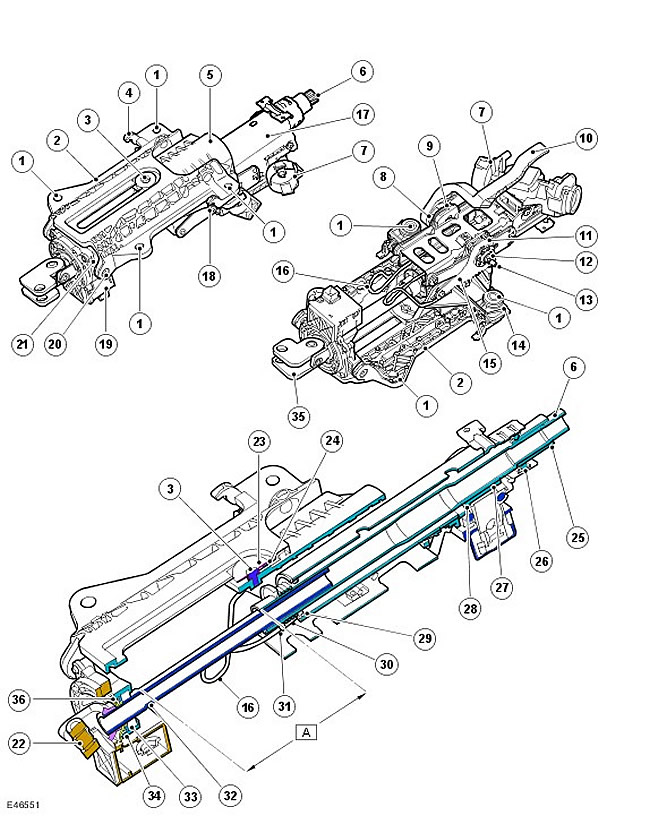

| Item name | Spare part number | Description |

| A | - | Crash compression stroke is 120.00 mm |

| 1 | - | Mounting holes |

| 2 | - | Top brace |

| 3 | - | Screw |

| 4 | - | fixing hook |

| 5 | - | U-bracket |

| 6 | - | Steering wheel slots |

| 7 | - | Complete lock |

| 8 | - | Cam disk |

| 9 | - | Cam disc assembly |

| 10 | - | Adjustment lever |

| 11 | - | Brake shoe |

| 12 | - | Lever nut |

| 13 | - | lever bolt |

| 14 | - | Shear capsule (2 pcs.) |

| 15 | - | Cam disc assembly |

| 16 | - | Adjusting balance spring (2 pcs.) |

| 17 | - | Main building |

| 18 | - | Ribbon (2 pcs.) |

| 19 | - | Steering angle sensor |

| 20 | - | Articulated pin |

| 21 | - | Hinge housing |

| 22 | - | cross |

| 23 | - | Sleeve |

| 24 | - | thrust washer (2 pcs.) |

| 25 | - | Upper shaft |

| 26 | - | Upper bearing |

| 27 | - | Ferrule |

| 28 | - | Retaining clutch |

| 29 | - | intermediate bearing |

| 30 | - | Spring |

| 31 | - | spring washer |

| 32 | - | lower shaft |

| 33 | - | Retaining ring |

| 34 | - | Universal Joint Seal |

| 35 | - | swivel fork |

| 36 | - | Lead flange |

The steering column is attached to the inner cross member with four 8mm low taper Torx self-tapping screws. The two front mounting screws go through the steering column support bracket and the two rear mounting screws also go through the shear capsules. In the event of a severe frontal impact, the shear capsules remain stationary on the crossbeam and the U-bracket (along with the main body) detaches from the capsules, allowing the column to shorten its axial length (take shape), while the annular belts absorb energy without completely transferring it to the driver.

CAUTION: Be careful when handling the steering column to avoid pinching your fingers when removing the adjustment lever during the removal procedure while the column is removed from the vehicle. The balancing springs will cause the column to quickly rise to the top position.

The column has a magnesium alloy top bracket that attaches to the vehicle's cross member. The hinge body, U-bracket, upper and lower shafts, and the main body are fixed to the upper bracket. The top brace has two hooks that fit into the grooves of the inner cross beam. Hooks help support the steering column during removal and installation.

The hinge body is attached to the front of the top bracket with two hinge pins. The hinge housing allows the tilt of the steering column to be adjusted and contains a bearing on which the column's lower shaft rests.

The U-bracket is secured to the top bracket with a screw, bushing, and plastic washer (third mount) into the slot at the top of the top bracket. When the speaker is installed in the car, the shear capsules attached to the U-bracket are pressed against the top bracket by screws, which prevents the U-bracket from moving. The bolts also pass through steel bands of rectangular section, twisted on one side around a plastic sleeve (mounted on a shear capsule). The bands are used to control the rate of compression of the steering column in the event of a severe frontal collision.

The main body is mounted on the U-bracket by means of a lever bolt. The bolt is fixed in the vertical slots of the U-bracket and the horizontal slots of the main body. Also the bolt goes through the clamping plates (one on each side of the U-bracket). In the housing there are intermediate and upper bearings through which the upper shaft passes. Two offset holes in the main body provide mounting for the steering column lock assembly.

The top and bottom rolls run along the column assembly. The upper shaft is supported by two bearings in the main body, while the lower shaft is inserted into the upper shaft and supported by a bearing in the pivot housing. The lower shaft has a tubular part with external splines. These splines engage with the inner splines of the top shaft. The splines transmit the rotation of the upper shaft to the lower shaft. In this case, the shafts can telescopically move relative to each other. The length of the splined parts providing linear movement is 120 mm. The lower shaft has a universal joint cross for attaching the swivel fork. The swivel yoke is attached to the intermediate steering column shaft on the inside of the bulkhead with a special cam bolt and self-locking nut.

The steering angle sensor is attached to the steering column pivot housing and its center gear is driven by a drive flange that is attached to the lower shaft and rotates with the steering wheel. The sensor transmits the steering angle value via a high-speed CAN bus, to which various vehicle systems are connected. The steering angle sensor is disconnected from the column during a frontal impact. When working on the steering column assembly, be careful not to accidentally damage the sensor. For more information refer to Anti-Lock Control -Traction Control (206-09A).

The top shaft has a locking collar that engages with the locking bolt of the column lock assembly. The locking collar is attached to the shaft with a retaining ring. The safety ring ensures that the shaft slips when a certain force is exceeded. This prevents the column lock from being damaged by applying excessive force to the steering wheel. The safety ring ensures that the upper shaft slips when the torque exceeds 200 Nm. To turn the locking collar further, the torque must exceed 100 Nm.

The steering column is adjustable in height and angle. The range of adjustment of the column in the longitudinal direction is 40 mm, and in the angle of inclination - 6°. The adjustment mechanism includes an adjustment lever, a cam washer, a lever bolt and nut, two brake shoes, and two clamp plate assemblies.

The plastic adjustment lever is mounted on the underside of the steering column and is attached to the cam. When the lever is moved down, the cam rotates and relieves pressure on the lever bolt. The lever bolt also goes through the two clamp plate assemblies. When the lever is moved up, the cam rotates and applies pressure to the lever bolt, which transmits pressure to the brake pads. The pads, in turn, press the clamping plate assembly, fixing the column in the desired position. The lever bolt is secured with a self-locking lever nut that rests on a thrust bearing.

CAUTION: Under no circumstances should the lever nut be loosened, as this will reduce the effective retention of the adjusting mechanism, which will affect the stability of the column during a frontal collision.

The hinge body is attached to the top bracket with two hinge pins. When adjusting the column inclination, the hinge body rotates relative to the hinge pins to raise and lower the column. At the same time, it maintains a constant position relative to the upper bracket. Between the U-bracket and the main body, an adjusting spring is installed to compensate for the mass of the main body, upper shaft, steering wheel and airbag. It prevents the steering wheel from dropping quickly when the adjustment lever is released.

In the event of a severe frontal collision, the top of the column assembly folds axially to reduce injury to the driver. Controlled folding of the column ensures the joint work of a number of components and parts. The following components and parts are involved in the controlled folding of the steering column:

- Thrust washer and bushing (third mount)

- Cut capsules

- Ribbons

- Spline connection of the upper and lower shafts

Shear capsules have central holes through which the rear mounting bolts are inserted into the upper bracket. Capsules are attached to the U-bracket with tapered grooves, which have small cutouts on the inner surface. The shear capsules have small diameter holes that match the cutouts on the U-bracket. When installing the capsules, the holes and cutouts are filled with plastic. The plastic capsule attachment provides a controlled initial column impact force. With a displacement of more than 10 mm, the U-bracket is no longer held by the shear capsules. When working on the steering column, be careful not to damage or dislodge the shear capsules.

Screw pressure "third mount" attached to the top bracket (through bushing and compression washers). In the event of a collision, this load (in addition to shear capsule resistance) must be overcome before the steering column folds. When this load is exceeded (and mount offset by 20 mm) the column is easily displaced in the groove of the upper bracket, folding in the required direction. Under no circumstances should the screw tightening torque be changed.

Tapes are made of steel of rectangular section. One of their ends is twisted around a plastic sleeve mounted on a shear capsule. The other end forms a hook that fits into a groove in the U-bracket.

If, in the event of a collision, the U-bracket is displaced by 8 mm relative to the shear capsules, the belts begin to unwind as a result of the movement of the U-bracket. The ribbons provide the main energy absorption when the column is folded. The cross-section of the tapes changes after stretching by approximately 40 mm, allowing you to adjust the amount of energy absorbed.

Comments on this article