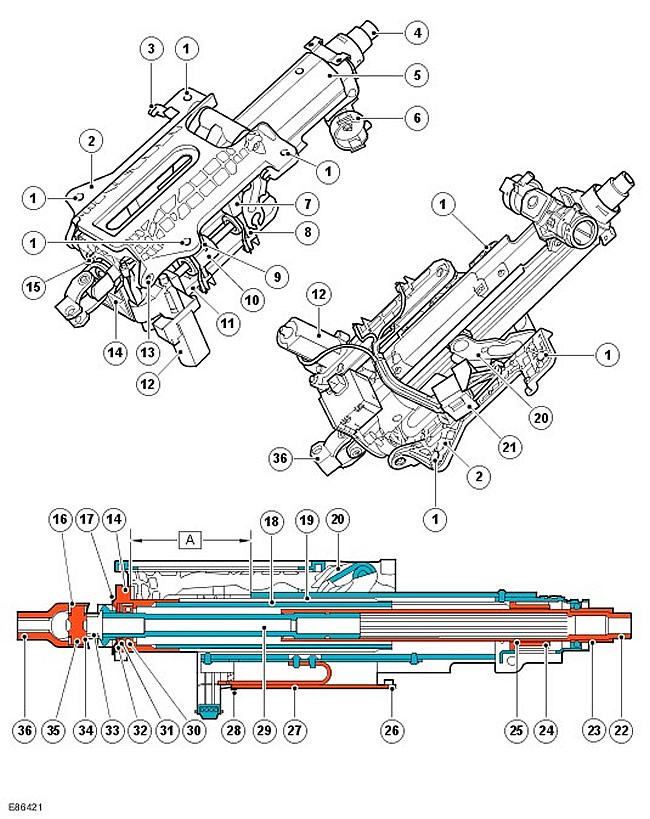

| Item name | Spare part number | Description |

| A | - | Crash compression stroke is 90.00mm |

| 1 | - | mounting hole |

| 2 | - | Top brace |

| 3 | - | fixing hook |

| 4 | - | Steering wheel slots |

| 5 | - | External profile |

| 6 | - | Complete lock |

| 7 | - | Tilt steering solenoid |

| 8 | - | Column Tilt Coupling |

| 9 | - | Fore/aft steering solenoid |

| 10 | - | Coupling device for longitudinal adjustment of the steering column |

| 11 | - | Potentiometer |

| 12 | - | electric motor |

| 13 | - | Articulated pin |

| 14 | - | Hinge housing |

| 15 | - | Steering angle sensor |

| 16 | - | Needle roller bearing |

| 17 | - | Lead flange |

| 18 | - | Internal profile |

| 19 | - | emergency beam |

| 20 | - | Tilt lever |

| 21 | - | electrical connector |

| 22 | - | Upper shaft |

| 23 | - | Upper bearing |

| 24 | - | Retaining clutch |

| 25 | - | Ferrule |

| 26 | - | Casing fastening clip |

| 27 | - | Ribbon |

| 28 | - | shear pin |

| 29 | - | lower shaft |

| 30 | - | Lower bearing |

| 31 | - | Washer |

| 32 | - | Retaining ring |

| 33 | - | clamp |

| 34 | - | Universal Joint Seal |

| 35 | - | cross |

| 36 | - | swivel fork |

An electrically adjustable steering column is standard on certain models and optional on other models.

The steering column is attached to the inner cross member with four 8mm low taper Torx self-tapping screws. In the event of a severe frontal impact, the band and shear pin on the underside of the speaker provide a controlled folding of the outer casing relative to the inner casing, allowing the speaker to shorten its axial length (take shape), while absorbing energy and not completely transferring it to the driver.

The column has a magnesium alloy top bracket that attaches to the vehicle's cross member. Mounted on the upper bracket are the hinge housing, the outer housing, and the upper and lower shafts. The top brace has two hooks that fit into the grooves of the inner cross beam. Hooks help support the steering column during removal and installation.

The tilt lever is mounted on an external aluminum profile, in which the steel steering column lock adapter is fixed (with top bearing). The inner profile is mounted inside the outer profile on two longitudinal holders, allowing telescopic movement of the steering column to adjust its longitudinal position.

The upper and lower shaft assemblies are located inside the column on bearings in the steering column lock adapter and hinge housing. Both shafts are tubular. The lower shaft has external splines (crimped with nylon). These splines engage with the internal splines in the top shaft. The splines transmit the rotation of the upper shaft to the lower shaft. In addition, the shafts can telescopically move relative to each other when the column is axially folded. The lower shaft has a universal joint cross for attaching the swivel fork. The swivel fork is attached to the intermediate steering column shaft on the inside of the bulkhead with a special cam bolt and self-locking nut.

The steering angle sensor is attached to the steering column pivot housing and its center gear is driven by a drive flange that is attached to the lower shaft and rotates with the steering wheel. The sensor transmits the steering angle value via a high-speed CAN bus, to which various vehicle systems are connected. The steering angle sensor is disconnected from the column during a frontal impact. When working on the steering column assembly, be careful not to accidentally damage the sensor. For more information refer to Anti-Lock Control -Traction Control (206-09A).

The top shaft has a locking collar that engages with the locking bolt of the column lock assembly. The locking collar is attached to the shaft with a retaining ring. The safety ring ensures that the shaft slips when a certain force is exceeded. This prevents the column lock from being damaged by applying excessive force to the steering wheel when the lock is locked. The safety ring ensures that the upper shaft slips when the torque exceeds 200 Nm. To turn the locking collar further, the torque must exceed 100 Nm.

The electric steering column adjuster can be used to adjust the tilt and fore/aft position. The column can be adjusted 40.00 mm in height and 6 degrees in inclination. The adjustment mechanism consists of an electric motor, a lead screw, a steering column tilt solenoid, a steering column tilt solenoid, a steering column tilt clutch, and a steering column tilt clutch.

The steering column is adjusted by the driver using the joystick located to the left of the steering column cover. Moving the joystick back and forth changes the steering column fore/aft accordingly, and moving the joystick up and down changes the steering column tilt accordingly. The same electric motor is used for both types of adjustment. The lever-regulator supplies voltage to one or another solenoid, which, in turn, engages with the corresponding clutch on the lead screw.

If the function is selected on the joystick "Auto", the steering column will rise to its highest position when the key is removed from the steering column lock cylinder and will return to its previous position when the key is reinserted.

For longitudinal adjustment of the steering column, the lead screw moves the outer housing forward or backward. When tilting the steering column, the lead screw moves the tilt lever, which raises or lowers the steering column as needed.

The hinge body is attached to the top bracket with two hinge pins. When adjusting the column inclination, the hinge body rotates relative to the hinge pins to raise and lower the column. At the same time, it maintains a constant position relative to the upper bracket.

The electronic memory control unit is responsible for the operation of the electric steering column adjustment unit. Three different sets of adjustment parameters are stored in the electronic memory control unit, which correspond to three individual car keys. For more information contact Seats (501-10 Seating).

In addition, the electric steering column adjustment unit has the function of raising the column to the maximum height, which makes it easier to get into the car.

In the event of a severe frontal collision, the top of the column assembly folds down to reduce driver injury. Controlled folding of the column ensures the joint work of a number of components and parts. The following components and parts are involved in the controlled folding of the steering column:

- shear pin

- Ribbon

- Spline connection of the upper and lower shafts

The band is a rectangular strip of steel that is secured with two hex head screws to the outer casing and a shear pin to the band guide. The tape is the main element used to absorb energy when the column is folded. In order for the axial movement of the steering column to begin, the shear pin must be cut, the friction between the multiple steering column mates must be overcome, and the applied axial load must be sufficient to initiate deformation of the guide band. When the steering column is telescopically folded, the deflection of the guide band and the sliding friction between the steering column mates allow the driver's energy to be absorbed in a controlled manner.

CAUTION: Do not attempt to disassemble the steering column. This can lead to a deterioration in the safety of this node.

Comments on this article