Removing

1.

WARNING: It is forbidden to carry out work on a vehicle supported only by a jack. Always place the vehicle on secure stands.

Raise and support the vehicle.

2. Remove the wheel and tire assembly.

3.

WARNING: Plug all open connections to avoid contamination of the system.

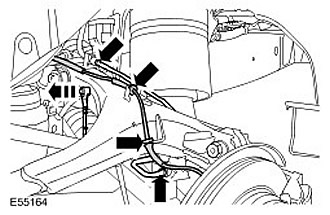

Remove the brake pipeline.

- Separate 2 connections of the brake pipeline.

- Remove the brake hose clamps and free the brake hoses. Release the brake pipe from the clamp.

4. Disconnect the height sensor link.

5. Disconnect the wheel speed sensor wire.

6. Right side only: Release the brake pad wear sensor wire.

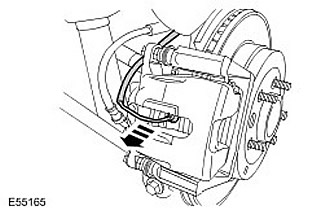

7. Remove the top arm.

- Loosen the upper arm bolts.

- Note the position of the bolt in relation to the upper arm.

- Remove the nut and bolt, then disconnect the upper arm from the wheel knuckle.

- Turn out bolts of the top lever.

Installation

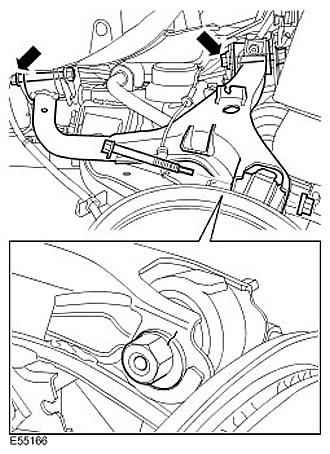

1. Install the upper arm. Insert the bolts, but do not fully tighten them yet.

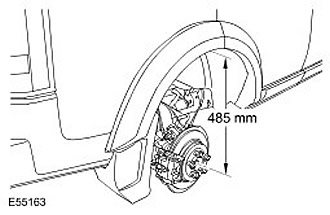

2. Set the distance from the center of the axle shaft to the edge of the wing so that it is 485 mm (19.10 inches). Install the bridge brace.

3.

CAUTION: Make sure that the protective boot of the ball joint is not damaged. Damage to the protective cover leads to premature failure of the ball joint.

Attach the upper arm to the wheel knuckle.

- Align the bolt to the previously made marks.

- tighten bolt (tightening torque 133 Nm).

4. Tighten the upper arm front bolt (tightening torque 175 Nm).

5. Tighten the upper arm rear bolt (tightening torque 175 Nm).

6. Attach the wheel speed sensor wire.

7. Attach the brake pad wear sensor wire.

8. Attach the height sensor arm.

9. Establish the brake pipeline. Tighten brake line connections (tightening torque 175 Nm).

10. Remove air from the brake system. For more information, refer to Bleeding the Brake System (70.25.02)

11. Install the wheel and tire assembly. Tighten wheel nuts (tightening torque 140 Nm).

12. Adjust wheel alignment.

Comments on this article