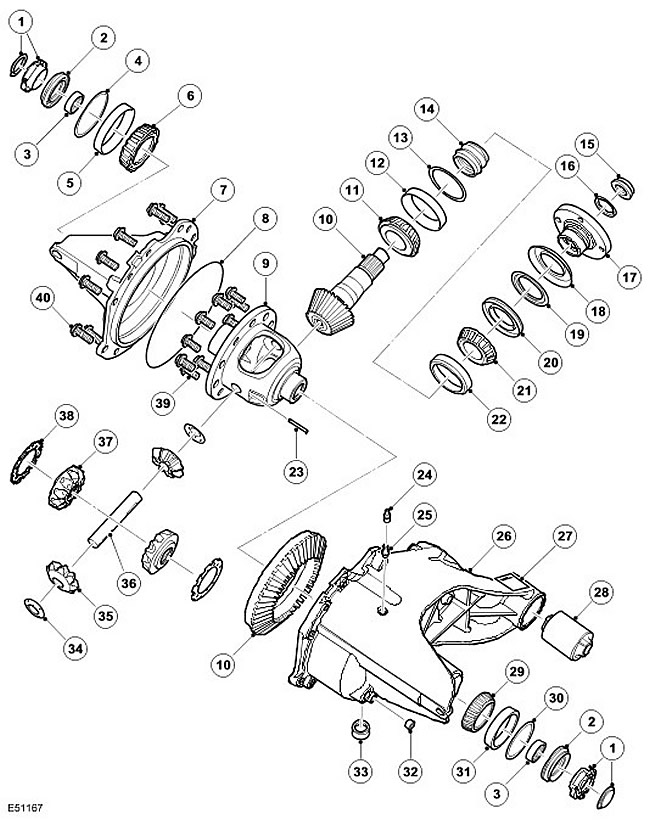

| Item name | Spare part number | Description |

| 1 | - | Lid |

| 2 | - | Seal |

| 3 | - | Bearing assembly without cage |

| 4 | - | Bearing preload spacer |

| 5 | - | Bearing |

| 6 | - | Roller bearing outer ring |

| 7 | - | Lid |

| 8 | - | Seal |

| 9 | - | differential cup |

| 10 | - | Gear assembly |

| 11 | - | Bearing |

| 12 | - | Roller bearing outer ring |

| 13 | - | Washer |

| 14 | - | Deformable spacer |

| 15 | - | Pinion nut |

| 16 | - | clamp |

| 17 | - | Flange |

| 18 | - | Outer deflector |

| 19 | - | Internal deflector |

| 20 | - | Oil seal |

| 21 | - | Bearing |

| 22 | - | Roller bearing outer ring |

| 23 | - | cylindrical pin |

| 24 | - | breather cap |

| 25 | - | Breather |

| 26 | - | Frame |

| 27 | - | Data location |

| 28 | - | Mounting sleeve |

| 29 | - | Bearing |

| 30 | - | Bearing preload spacer |

| 31 | - | Roller bearing outer ring |

| 32 | - | Stub |

| 33 | - | drain plug |

| 34 | - | thrust washer |

| 35 | - | planetary gear |

| 36 | - | cross shaft |

| 37 | - | sun wheel |

| 38 | - | thrust washer |

| 39 | - | Bolt, 10 pcs. |

| 40 | Bolt, 12 pcs. |

The cast iron body consists of two parts: a cup and a lid. The cup contains all the internal parts. The cup is attached to the lid with 12 bolts, and the junction is sealed with an O-ring. Lid and cup have molded ribs for increased portability. A breather tube is fixed at the top of the cup. This allows you to install a plastic tube and lead it out at a high point under the car body to prevent water from entering when the car is wading.

The cup has a drain plug for oil. The capacity of the differential is approximately 1.6 liters when dry filled. Subsequent oil changes will require less oil due to the non-draining residue in the gear case.

The differential has a traditional hypoid gear design similar to that used in the front differential. There are 3 types of open type rear differentials with different gear ratios. V8 gasoline vehicles use a 3.73:1 final drive differential, V6 gasoline vehicles use a 3.73:1 final drive differential. In cars with a TdV6 engine and an automatic transmission, the final drive ratio is 3.54, and with a manual transmission it is 3.07. Changing the number of teeth between the driven gear and the final drive gear results in a change in gear ratio.

The differential consists of a pinion shaft, a hypoid gear and a final drive gear with an integral housing housing 2 planetary gears. The housing also houses 2 sun gears that transmit torque to the drive shafts.

The pinion shaft is mounted on 2 opposing tapered roller bearings with a deformable sleeve in between. The sleeve is used to center the bearings and, moreover, is deformed when force is applied to the flanged gear nut. This allows the flange nut to be tightened to a predetermined torque that deforms the sleeve to provide the required bearing preload.

The pinion shaft has an externally splined outer end that engages with the primary flange, which is fastened with a pinion nut and clamp. The primary flange has 4 threaded holes and connects to the rear drive shaft. 4 bolts secure the rear drive shaft to the primary flange. A gland is pressed into the gear case, which seals the connection of the primary flange with the gear case. A hypoid gear is installed from the inner end of the gear shaft, which engages with the driven gear of the final drive.

The driven gear is located on the differential case and is fixed with 10 screws. The differential housing is mounted on tapered roller bearings placed in machined holes on both sides of the gear boat. The washers are held in the housing behind the bearing caps; their thickness is chosen in such a way as to provide the required bearing preload and hypoid gear play.

The differential cup has a through hole for the shaft. The shaft is supported by a sun gear and a needle roller bearing. At one end of the shaft there is a retaining ring that fits into a machined groove in the sun gear to lock the shaft into position.

The sun gears are located in the recesses of the cup body and engage with the planetary gears. Distance bushings are installed between the sun gears and the cup to ensure proper engagement of the sun and planetary gears. Each sun gear has an internally splined machined bore and a machined groove near the splined end. This groove secures the retaining ring installed at the end of each outlet flange.

Each output shaft has a spline that engages with a sun gear. A retaining ring mounted on the splined shaft fits into the sun gear hole groove and firmly fixes the output shaft. On each side of the gear housing, oil seals are pressed in to seal the output shaft.

Comments on this article