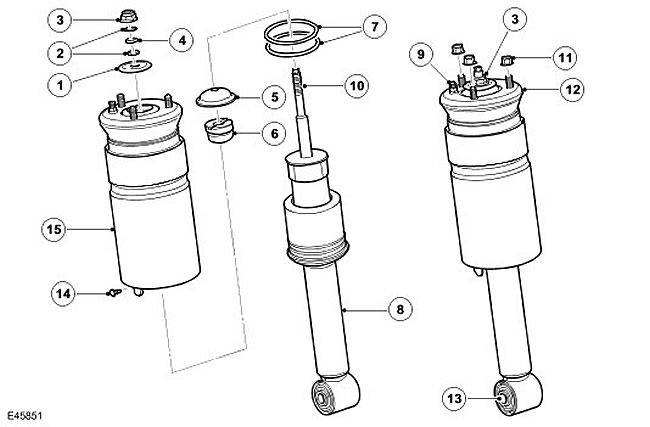

| Item name | Spare part number | Description |

| 1 | - | Spring washer* |

| 2 | - | shock absorber rod o-ring (2 pcs.) * |

| 3 | - | Self-locking nut* |

| 4 | - | Shock absorber bushing* |

| 5 | - | buffer washer |

| 6 | - | Elastic Element Auxiliary* |

| 7 | - | O-ring for fastening the cylinder of an elastic pneumatic element (2 pcs.) * |

| 8 | - | Shock absorber assembly* |

| 9 | - | Pneumatic fitting type Voss |

| 10 | - | shock absorber rod |

| 11 | - | Self-locking nut (3 pcs.) |

| 12 | - | Upper support |

| 13 | - | Sleeve |

| 14 | - | Fixing pin of elastic pneumatic element assembly* |

| 15 | - | Elastic pneumatic element assembly* |

NOTE: * repairable parts

The shock absorber module includes an elastic pneumatic element assembly, an upper support and a shock absorber assembly. The shock absorber and the elastic pneumatic element are subject to maintenance only as a single unit.

Shock absorber

The shock absorber assembly has a two-tube design, in which the conventional spring is replaced by an elastic pneumatic element. The lower end of the shock has a bushing that attaches to the lower control arm with a bolt and nut.

The damping capacity of the shock absorber is determined by the limitation of the flow of the working fluid through the internal channels of the shock absorber. The movement of the rod along the axis of the shock absorber is limited by the flow of fluid through the channels. This provides damping of vibrations that occur when the car is moving on rough roads. A seal is installed at the point where the shock absorber rod exits the shock absorber body, which does not allow fluid to flow out of the shock absorber and prevents dirt and moisture from penetrating into the shock absorber. In addition, this seal contains a stem cleaner.

Pneumatic elastic element

The pneumatic elastic element includes an aluminum cylinder, an upper support, an auxiliary device of the elastic element, an air spring and an internal support sleeve.

The air spring is made of a flexible rubber material that folds and unfolds to allow the air spring piston to move vertically as the vehicle height changes. The pneumocylinder is attached to the cylinder and the support sleeve with ferrules, which ensure the tightness of the connection. The support sleeve contains a seal housing containing two O-rings sealing the support sleeve and two O-rings sealing the shock absorber housing. The upper part of the bellows is attached to the upper support mounted on the chassis frame with 3 built-in studs and self-locking nuts.

The auxiliary device of the elastic element is installed on the shock absorber rod. It prevents the upper mount from contacting the top of the shock when the suspension is fully compressed, and also helps to tune the suspension. The lower part of the elastic pneumatic element is installed above the shock absorber body and is seated on the machined surface of the shock absorber body. The pneumocylinder is rigidly attached to the landing surface with a fixing pin. The shock absorber rod passes through the central hole of the upper support. The outer end of the rod is threaded. A self-locking nut is used to fasten the pneumatic elastic element to the shock absorber rod.

The upper support is an integral part of the pneumatic elastic element and is equipped with a sleeve and an elastic washer. A buffer washer is installed between the upper support plate and the shock absorber rod. The upper support is fixed on the shock absorber rod with a self-locking nut. The top support is attached to the body on the chassis with 3 built-in studs and self-locking nuts. The top plate also has a 6mm Voss fitting for connecting the air line.

By order, a cover can be installed by the dealer. The cover has the same design as the cover installed on the rear air shock absorber module. It can be installed if dirt and debris get between the air spring and the cylinder under certain road conditions.

Comments on this article