Special tool

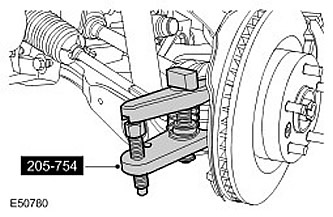

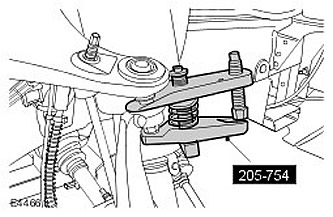

Ball joint puller 205-754 (LRT-54-027)

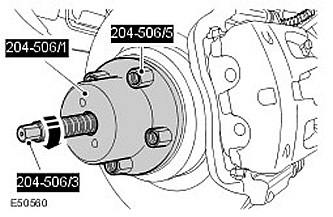

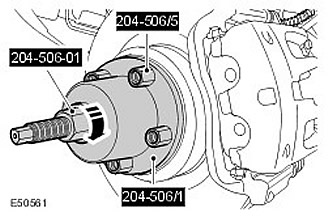

Ball joint puller 205-754 (LRT-54-027) |  Tool for dismantling/replacing axle shafts 204-506/1 (LRT-60-030/1)

Tool for dismantling/replacing axle shafts 204-506/1 (LRT-60-030/1) |  Tool for dismantling/replacing axle shafts 204-506/3 (LRT-60-030/3)

Tool for dismantling/replacing axle shafts 204-506/3 (LRT-60-030/3) |

Tool for dismantling/replacing axle shafts 204-506-01

Tool for dismantling/replacing axle shafts 204-506-01 |  Holders - tool for dismantling/replacing axle shafts 204-506/5 (LRT-60-030/5)

Holders - tool for dismantling/replacing axle shafts 204-506/5 (LRT-60-030/5) |  Drive axle oil seal remover 308-005 (LRT-37-004/2)

Drive axle oil seal remover 308-005 (LRT-37-004/2) |

Pulse extractor 100-012 (LRT-99-004)

Pulse extractor 100-012 (LRT-99-004) |  Mounting tool/shaft oil seal guide 308-626/2

Mounting tool/shaft oil seal guide 308-626/2 |  Axle shaft seal mounting tool 308-626/1

Axle shaft seal mounting tool 308-626/1 |

Removing

CAUTION: To avoid damage to the ball joint, do not store or install the axle shafts in the maximum retracted position

CAUTION: To avoid damage to the ball joint, do not allow the axle shaft to hang unsecured on one side.

WARNING: Roller joints type AAR (Angularly Adjusted Roller), mounted on the inside of some axle shafts, do not have an internal retaining mechanism and therefore may come apart.

1.

WARNING: It is forbidden to carry out work on a vehicle standing on only one jack. Always support the vehicle with jack stands.

Raise and support the vehicle.

2. Drain the differential oil. For more information, refer to Draining the Gear Oil from the Differential and Filling the Differential with Gear Oil (54.15.02)

3. Remove the wheel.

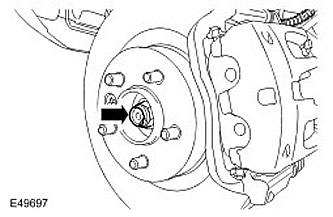

4. Loosen the axle shaft nut. Discard the nut.

5.

CAUTION: Use the included hex wrench to prevent the ball joint from turning.

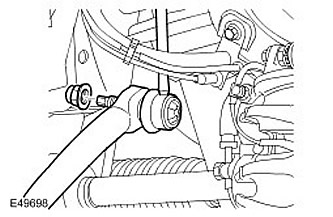

Detach the right stabilizer link. Loosen and discard the nut.

6.

CAUTION: Use the included hex wrench to prevent the ball joint from turning.

Loosen the stabilizer bar nut. Loosen and discard the nut.

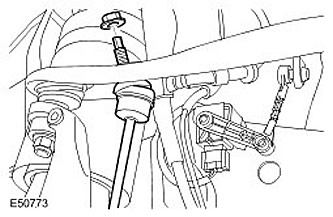

7. Disconnect the brake hose bracket from the wheel knuckle. Turn out a bolt.

8. Loosen the nut securing the ball joint to the tie rod.

9.

CAUTION: Make sure that the protective cover is not damaged. Damage to the protective hinge leads to premature failure of the hinge.

Using the special tool, disconnect the tie rod ball joint from the steering knuckle. Discard the nut.

10.

CAUTION: Support the steering knuckle to prevent the steering knuckle from falling forward and disengaging the axle shaft inner joint.

Loosen the upper arm mounting nut.

11.

CAUTION: Make sure that the protective cover is not damaged. Damage to the protective cover leads to premature failure of the hinge.

Using the special tool, disconnect the upper control arm ball joint. Remove the nut and discard it.

12.

CAUTION: Excessive bending can damage the lower arm ball joint. It is necessary to constantly support the steering knuckle. Do not allow the steering knuckle to hang on the lower control arm. Failure to follow this instruction may result in damage to the vehicle.

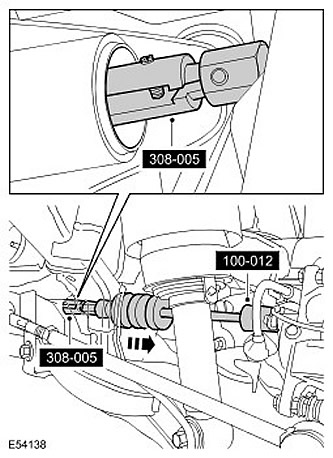

Using the special tools, disconnect the axle shaft from the wheel hub.

13. Disconnect the axle shaft from the steering knuckle.

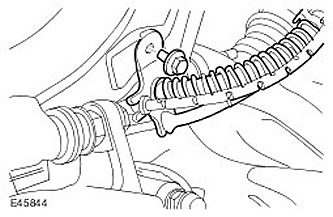

14. Remove the axle shaft from the differential housing.

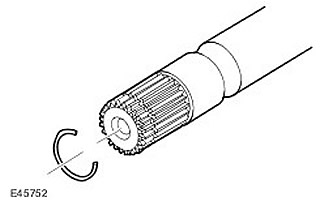

15. Remove the half shaft.

- Raise the stabilizer so that the axle shaft can be removed.

- Remove the snap ring and discard it.

16. Using the special tools, remove the axle shaft seal and discard it.

Installation

1. Clear the details.

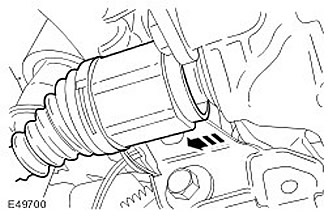

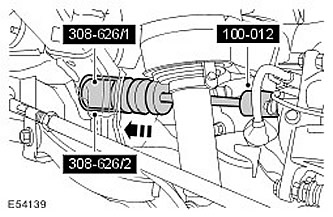

2. Using the special tools, install a new axle shaft seal. Do not open the axle shaft seal until the axle shaft is fully seated.

3.

NOTE: Do not fully insert axle shaft until seal guard has been removed.

Install the axle shaft.

- Install retaining ring.

- Lubricate the seal and bearing surfaces with clean gear oil.

- Make sure the circlip is fully seated and is holding the axle shaft.

- Open the axle shaft seal.

4.

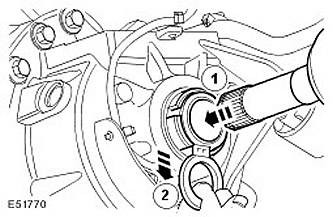

NOTE: The shaft seal guard should come apart in two.

Remove and discard the axle shaft seal guard.

5.

CAUTION: Excessive bending can damage the lower arm ball joint. It is necessary to constantly support the steering knuckle. Do not allow the steering knuckle to hang on the lower control arm. Failure to follow this instruction may result in damage to the vehicle.

Using the special tools, install the axle shaft into the wheel hub.

6. Attach the upper arm to the wheel knuckle. Screw on the new nut and tighten it (tightening torque 70 Nm).

7. Attach the stabilizer bar. Screw on the new nut and tighten it (tightening torque 115 Nm).

8. Attach the tie rod ball joint. Screw on the new nut and tighten it (tightening torque 76 Nm).

9. Install a new axle nut and tighten slightly.

10. Attach the brake hose bracket to the steering knuckle. Wrap the bolt (tightening torque 22 Nm).

11. Attach the right stabilizer link. Screw on the new nut and tighten it (tightening torque 115 Nm).

12. Tighten the new axle shaft nut (tightening torque 350 Nm). Fasten the nut on the axle shaft.

13. Install wheels. Tighten wheel nuts (tightening torque 140 Nm).

14.

ATTENTION: Do not fill the differential with oil up to the hole in the filler plug. The fill plug hole is only used to fill the differential with oil and cannot serve as a level indicator.

Pour the required amount of oil into the differential. For more information, refer to Draining the Gear Oil from the Differential and Filling the Differential with Gear Oil (54.15.02)

Comments on this article