Removing

1.

WARNING: It is forbidden to carry out work on a vehicle standing on only one jack. Always support the vehicle with jack stands.

Raise and support the vehicle.

2. Use T4 to release pressure from the air suspension.

For more information, refer to Relieving and Boosting Air Suspension System Pressure (60.50.38)

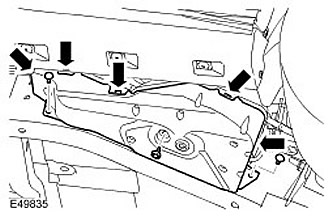

3. Remove the air suspension compressor lower cover.

- Turn out 3 bolts.

- Release 5 clips.

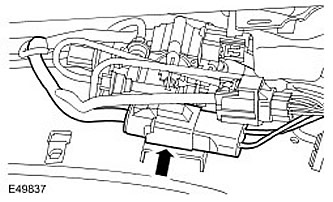

4. Set aside the air compressor electrical connector. Release 2 clips.

5.

CAUTION: Make sure the area around the contact surfaces is clean and dry before you start to disconnect or remove parts. Plug all open connections to avoid contamination of the system.

CAUTION: Visually inspect air line ends for damage or wear. Repair or replace the air line as needed.

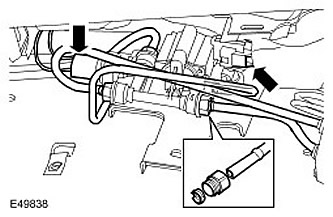

NOTE: Note the position of the air lines.

Remove the air suspension solenoid valve block.

- Disconnect 4 air lines.

- Disconnect the two electrical connectors.

- Loosen the three rubber pads on the valve block.

6. Remove the Voss fittings. Remove and discard taper bushings and couplers.

Installation

1.

CAUTION: Make sure the new Voss fitting is installed and fully tightened with corrector plug installed.

NOTE: New air suspension parts are shipped with Voss fittings installed and already torqued. If a new part is installed, it is not necessary to install new Voss fittings.

Install new Voss fittings to the air suspension solenoid valve block. Tighten connection (tightening torque 2.5 Nm).

2.

NOTE: Be careful not to detach the valve block when connecting the air lines.

Install the air suspension solenoid valve block.

- Install the three valve block rubber pads.

- Connect electrical connectors.

- Connect the air lines to the Voss fittings.

- Pull on each air line to make sure it is securely seated in the Voss fitting.

3. Connect the air compressor electrical connector.

4. Install the air suspension compressor lower cover. Insert bolts and tighten them (tightening torque 10 Nm).

5. Use T4 to pressurize the air suspension. For more information, refer to Relieving and Boosting Air Suspension System Pressure (60.50.38)

Comments on this article