Removing

NOTE: New air suspension components are shipped with Voss fittings fitted to them and pre-torqued. Therefore, in case of installing a new element, do not install new Voss fittings.

1. Use T4 to depressurize the air suspension. For more information, refer to Relieving and Boosting Air Suspension System Pressure (60.50.38)

2.

WARNING: It is forbidden to carry out work on a vehicle supported only by a jack. Always place secure supports under the vehicle.

Raise and support the vehicle.

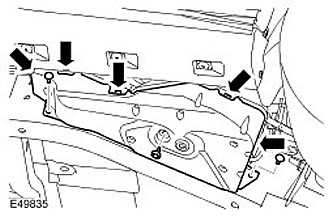

3. Remove the air suspension air compressor bottom cover.

- Turn out 3 bolts.

- Open 5 latches.

4.

WARNING: Plug all open connections to avoid contamination of the system.

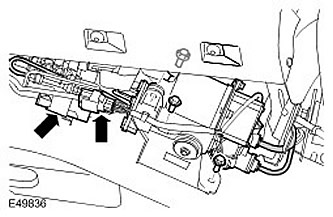

NOTE: Access to the upper compressor fixing bolt is very limited. It is recommended to use a 1/4" square drive socket and a universal joint adapter.

Remove the air suspension air compressor.

- Disconnect 3 air lines.

- Disconnect the two electrical connectors.

- Turn out three bolts.

Installation

1.

CAUTION: Make sure that the air suspension harness and lines are not pinched by the air suspension air compressor mounting bracket.

CAUTION: Correctly align the air suspension air compressor top cover.

NOTE: Before installing the two bottom bolts, install but do not fully tighten the top bolt.

Install the air suspension air compressor.

- Tighten the bolts to 10 Nm.

- Connect air lines.

- Connect electrical connectors.

2. Install the air suspension air compressor lower cover. Screw in the bolts and tighten them (tightening torque 9 Nm).

3. Use T4 to pressurize the air suspension. For more information, refer to Relieving and Boosting Air Suspension System Pressure (60.50.38)

Comments on this article