Removing

NOTE: During storage, a small amount of oil may leak from the drive shaft joints. This loss of oil does not affect the function or life of the joint in any way.

1.

WARNING: It is forbidden to carry out work on a vehicle standing on only one jack. Always support the vehicle with jack stands.

Raise and support the vehicle.

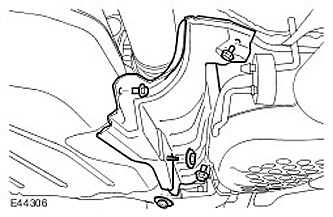

2. Remove the fuel tank heat shield. Remove 3 bolts and 2 nuts.

3.

CAUTION: Mark the position of the propshaft flange in relation to the pinion flange.

CAUTION: To avoid damaging the pivot or boot, do not allow the drive shaft to hang unsecured on one side.

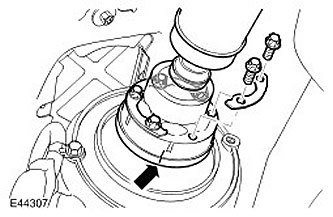

Disconnect the drive shaft from the transfer case drive flange. Remove 6 Torx head screws and washers.

4.

CAUTION: Mark the position of the propshaft flange in relation to the pinion flange.

CAUTION: To avoid damaging the pivot or boot, do not allow the drive shaft to hang unsecured on one side.

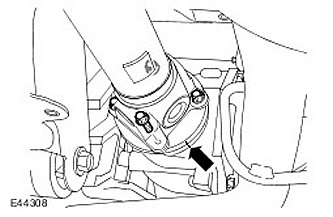

Disconnect the drive shaft from the rear axle drive flange. Remove and discard 4 Torx head screws.

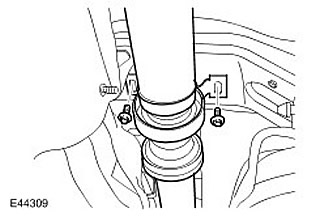

5. After inviting an assistant, remove the drive shaft. Turn out 2 bolts of fastening of a support of the central bearing of a power shaft.

Installation

1.

NOTE: During storage, a small amount of oil may leak from the drive shaft joints. This loss of oil does not affect the function or life of the joint in any way.

Connect the drive shaft to the rear axle drive flange.

- Clean the contact surfaces of the parts.

- Connect the drive shaft to the rear axle drive flange.

- Tighten new Torx bolts (tightening torque 150 Nm).

2.

NOTE: During storage, a small amount of oil may leak from the drive shaft joints. This loss of oil does not affect the function or life of the joint in any way.

Connect the drive shaft to the transfer case drive flange.

- Clean the contact surfaces of the parts.

- Tighten new Torx bolts (tightening torque 55 Nm).

3.

CAUTION: Align the driveshaft center bearing support by sliding the floating front of the shaft back or forward to match the holes in the support with the holes in the chassis.

CAUTION: Make sure the center bearing support is not under tension.

Wrap fixing bolts of a support of the central bearing of a power shaft.

- Align the center bearing support.

- Tighten the mounting bolts of the central bearing of the drive shaft (tightening torque 30 Nm).

4. Install the fuel tank heat shield.

- Tighten the bolts (tightening torque 6 Nm).

- Tighten the bolts (tightening torque 3 Nm).

Comments on this article