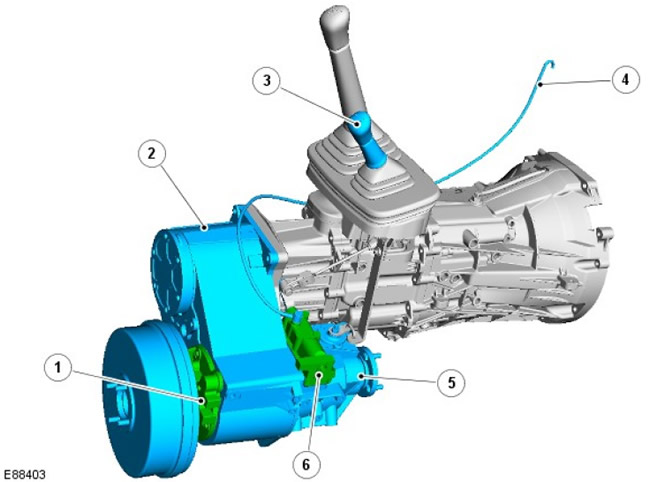

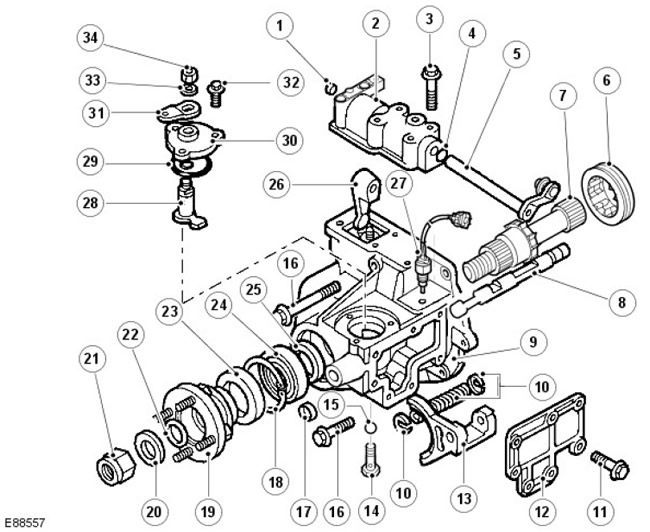

Location of elements

| Pos. | spare part no | Name |

| 1 | - | Rear axle drive shaft housing |

| 2 | - | Main crankcase |

| 3 | - | Transfer case selector lever |

| 4 | - | Ventilation piping |

| 5 | - | Front axle drive shaft housing |

| 6 | - | selector housing |

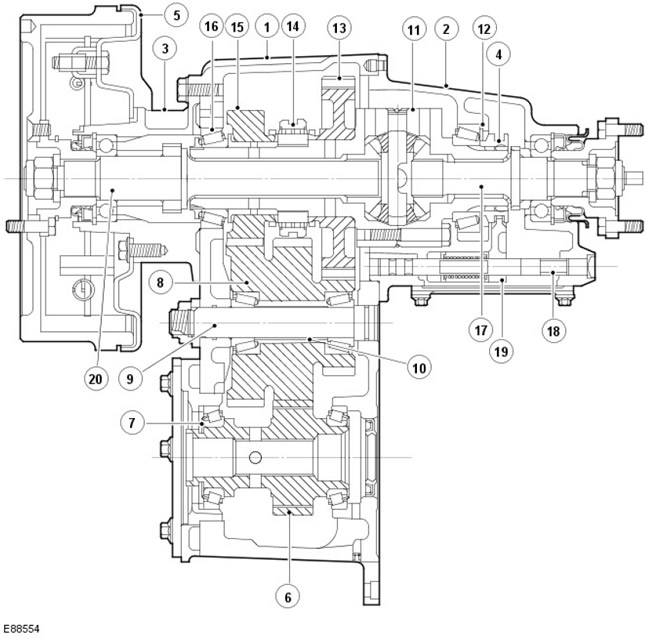

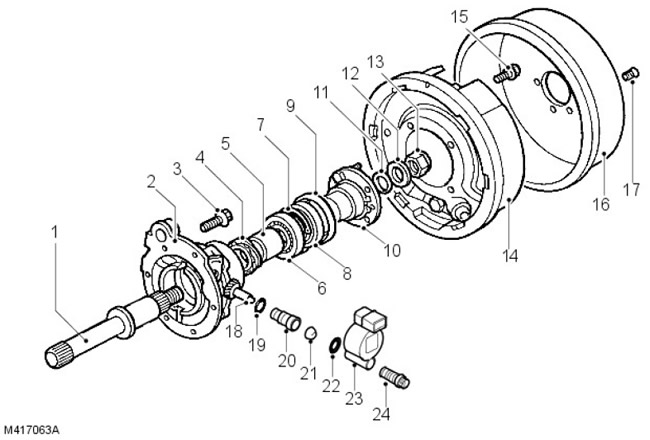

Transfer box cross section

| Pos. | spare part no | Name |

| 1 | - | Main crankcase |

| 2 | - | Front axle drive shaft housing |

| 3 | - | Rear axle drive shaft housing |

| 4 | - | dog clutch |

| 5 | - | transmission brake |

| 6 | - | Output shaft drive gear |

| 7 | - | Selective shim for setting pinion bearing preload |

| 8 | - | Block of intermediate gears |

| 9 | - | intermediate shaft |

| 10 | - | spacer |

| 11 | - | Differential assembly |

| 12 | - | Selective differential bearing preload shim |

| 13 | - | Low range gear |

| 14 | - | Bushing and hub for high/low selector |

| 15 | - | High range pinion and bushing |

| 16 | - | Rear differential bearing |

| 17 | - | Front axle drive shaft |

| 18 | - | Differential lock selector shaft |

| 19 | - | selector fork |

| 20 | - | Rear axle drive shaft |

Review

Transfer case handles permanent 4WD operation, provides two-stage downshifting, combines high and low range outputs with a mechanically lockable center differential (mode "diff-lock"). The high range is characterized by a gear ratio of 1.211:1 and the low range by 3.269:1.

Choice of high or low range and mode "diff-lock" is carried out using a single lever located near the main gear lever.

The transfer box is installed at the rear of the main gearbox, and through the cardan shafts transmits the movement to the differentials of the front and rear axles.

The differential assembly is integrated with the drive shafts to compensate for the speed difference between the front and rear drive shafts. To improve traction and prevent all power from being transferred to the drive axle differential for the sake of adding the slightest amount of traction, there is a mode "diff-lock". Mode "diff-lock" should only be enabled in severe off-road conditions where traction is low. It should be turned off as soon as possible, for example, when it is possible to develop a sufficiently large tractive effort. Engaging the differential lock mechanically engages the dog clutch on the front drive shaft, locking the center differential and providing a fixed drive that sends equal power to the front and rear drive shafts.

The transfer box contains 3 main components:

- Main crankcase

- Front axle drive shaft housing

- Rear axle drive shaft housing

All cases and covers are sealed to the main crankcase with sealant. The rotary seals on the outlet flange are protected from dirt and water by special baffles.

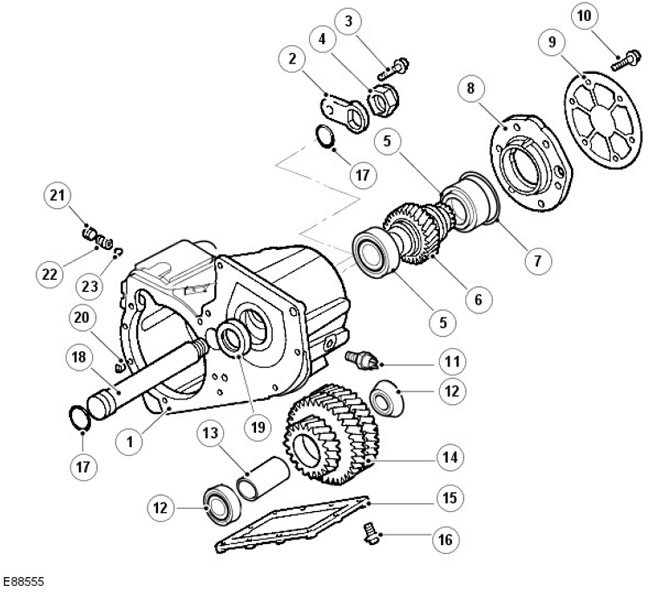

Main crankcase

| Pos. | spare part no | Name |

| 1 | - | Main crankcase |

| 2 | - | lock washer |

| 3 | - | Lock plate bolt |

| 4 | - | screw (with pin lock) intermediate shaft |

| 5 | - | Bearings and outer races of bearings of the input shaft drive gear |

| 6 | - | Output shaft drive gear |

| 7 | - | Selective shim |

| 8 | - | Main gear bearing housing |

| 9 | - | Cover/ power take-off cover |

| 10 | - | cover bolt |

| 11 | - | Oil temperature switch (if it is installed) |

| 12 | - | Bearings and outer rings of bearings of intermediate gears |

| 13 | - | Collapsible spacer |

| 14 | - | Intermediate gears |

| 15 | - | bottom cover |

| 16 | - | Bottom cover bolt |

| 17 | - | intermediate shaft sealing rings |

| 18 | - | intermediate shaft |

| 19 | - | Output shaft oil seal |

| 20 | - | locating pin |

| 21 | - | High/low selector locking plug |

| 22 | - | High/low range selector retaining spring |

| 23 | - | Locking ball for high/low range selector |

The main crankcase carries:

- output shaft drive gear

- intermediate gears

- center differential assembly

The front and rear axle drive shaft housings are bolted to each side of the main crankcase.

Output shaft drive gear

The gearbox output shaft is splined to the output shaft drive gear which is supported by tapered roller bearings.

The pinion bearing preload is provided by a selective shim located in the bearing housing.

Intermediate gears

The intermediate gear block is supported by tapered roller bearings located at each end of the block and placed on the intermediate shaft, which in turn is supported front and rear in the main housing.

The intermediate gear bearing preload is provided by a deformable spacer located between the bearings. The compression force applied to the spacer is generated by means of a nut located at the end of the intermediate shaft.

To install bearings, the diameter of the hole of the intermediate gear on each side is machined with a ledge.

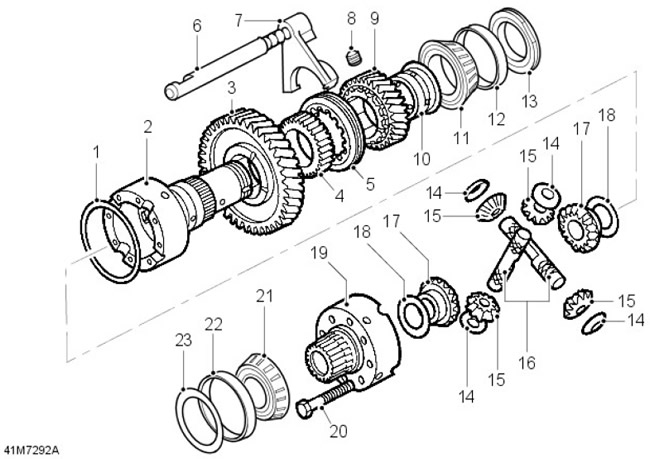

Center differential assembly

| Pos. | spare part no | Name |

| 1 | - | Retaining ring |

| 2 | - | Differential cup - rear section |

| 3 | - | Low range gear |

| 4 | - | High/low range hub |

| 5 | - | High/low selector sleeve |

| 6 | - | High/low selector shaft |

| 7 | - | High/Low selector fork |

| 8 | - | High/low selector fork set screw |

| 9 | - | high range gear |

| 10 | - | High Range Gear Bushing |

| 11 | - | Rear differential bearing |

| 12 | - | Bearing outer ring |

| 13 | - | Bearing nut |

| 14 | - | Cupped thrust washers |

| 15 | - | Differential planetary gears |

| 16 | - | axes |

| 17 | - | Bevel gears |

| 18 | - | Selective Thrust Washers |

| 19 | - | Differential cup - front section |

| 20 | - | Differential cup bolt |

| 21 | - | Front differential bearing |

| 22 | - | Bearing outer ring |

| 23 | - | Selective shim |

The center differential assembly front and rear is supported by tapered roller bearings; the front bearing outer race is located in the front axle drive shaft housing, and the rear bearing outer race is located in the main crankcase near the rear axle drive shaft housing. The bearing preload is provided by a selectively selected shim located in the front axle drive shaft housing.

The rear axle of the center differential contains the low range gear, the high/low range selector bush and hub, the high range gear and bush, and the differential rear bearing. These elements are fixed on the shaft with a special nut.

The differential assembly includes front and rear cup sections with built-in axles connected to axle bevel gears and pinion gears mounted on axles in the cup sections. Non-selective cupped thrust washers control pinion gear engagement with the side bevel gears, while selective thrust washers are used to control the side bevel gear engagement and the torque required to turn the differential. The differential cup sections are bolted together. The retaining ring ensures the exact position of the axes.

The high/low range selector shaft and fork are located on the side of the differential. Movement of the selector shaft, fork and sleeve is controlled by the high/low range selector finger. A spring-loaded detent ball mounted in the main body sits in grooves on the shaft.

The selector fork is spring-loaded and equipped with clamps that reduce the effort required to move the selector lever.

Front axle drive shaft housing

| Pos. | spare part no | Name |

| 1 | - | hollow plug |

| 2 | - | High/low range cross shaft housing |

| 3 | - | Cross Shaft Housing Bolt High/Low Ranges |

| 4 | - | O-ring |

| 5 | - | High/Low Cross Shaft and Cable Ball Lever |

| 6 | - | dog clutch |

| 7 | - | Front axle drive shaft |

| 8 | - | Differential lock selector shaft |

| 9 | - | Front axle drive shaft housing |

| 10 | - | Differential lock spring and clips |

| 11 | - | cover bolt |

| 12 | - | Lid |

| 13 | - | Differential lock selector fork |

| 14 | - | Locking plug and differential lock spring |

| 15 | - | Locking ball for differential lock |

| 16 | - | Front axle drive shaft housing bolt |

| 17 | - | Stub |

| 18 | - | Retaining ring |

| 19 | - | Drive shaft flange and mudguard |

| 20 | - | steel washer |

| 21 | - | Self-locking nut |

| 22 | - | Felt pad |

| 23 | - | Stuffing box |

| 24 | - | Drive shaft bearing |

| 25 | - | Bearing spacer |

| 26 | - | High/low selector finger |

| 27 | - | Differential lock indicator switch |

| 28 | - | Differential lock selector pin and shaft |

| 29 | - | O-rings of circular cross-section |

| 30 | - | Differential lock selector housing |

| 31 | - | Selector |

| 32 | - | Body bolt |

| 33 | - | Washer |

| 34 | - | Self-locking nut |

The front axle drive shaft housing carries:

- shaft and flange drive front axle

- housing and selector

- fork and selector shaft of the differential lock

The front axle drive shaft is supported in the housing by a single bearing and is splined to the front differential sun gear.

Housing and selector assembly

The high/low crossshaft is housed in a housing that is bolted to the top of the driveshaft housing and connects to the high/low pin that is located in a slot in the selector shaft.

Fork and shaft of the selector of the device of blocking of differential

The differential lock selector housing is bolted to the top of the front driveshaft housing. The selector pin extends through the housing and is located in a groove in the differential lock selector shaft. The differential lock selector shaft passes through the selector yoke, which is located below a plate bolted to the side of the drive shaft housing. When the bushing and rear differential shaft keys are aligned with each other, the selector fork engages the dog clutch bushing with the rear differential shaft. A spring-loaded detent ball mounted in the drive shaft housing is located in grooves on the shaft.

Rear axle drive shaft housing

| Pos. | spare part no | Name |

| 1 | - | Rear axle drive shaft |

| 2 | - | Rear axle drive shaft housing |

| 3 | - | Rear axle drive shaft housing bolt |

| 4 | - | Speedometer drive gear |

| 5 | - | spacer |

| 6 | - | Drive shaft bearing |

| 7 | - | Retaining ring |

| 8 | - | Stuffing box |

| 9 | - | Mudguard |

| 10 | - | drive shaft flange |

| 11 | - | Felt pad |

| 12 | - | steel washer |

| 13 | - | Self-locking nut |

| 14 | - | Transmission brake shield |

| 15 | - | Transmission brake shield bolt |

| 16 | - | transmission brake drum |

| 17 | - | Countersunk screw |

| 18 | - | speedometer driven gear |

| 19 | - | O-ring |

| 20 | - | speedometer driven gear housing |

| 21 | - | Pad |

| 22 | - | O-ring |

| 23 | - | Vehicle speed sensor (if it is installed) |

| 24 | - | Hex socket screw (in the presence of) |

The housing of the rear axle drive shaft contains the rear axle drive shaft and the flange, as well as the speedometer drive and driven gears. Connected to the housing is a mechanically actuated transmission brake where the brake drum is attached to the output flange.

The rear axle drive shaft is supported in a suitable housing by a single bearing and is splined to the differential rear shaft. The drive shaft also houses the speedometer drive gear, which meshes with the speedometer driven gear located in the rear axle drive shaft housing.

The differential lock indicator light switch, activated by movement of the fork and selector shaft, is screwed into the top of the drive shaft housing.

Lubricant

Splash lubrication, fill/check plugs and drain plug are located in the main body.

The increase in internal pressure caused by thermal expansion and contraction can be avoided by using a plastic ventilation duct, through which gases are removed from the interior of the box to the atmosphere. This line connects to the top of the high/low selector housing and ascends continuously to the engine compartment, where its open end is attached to the engine block.

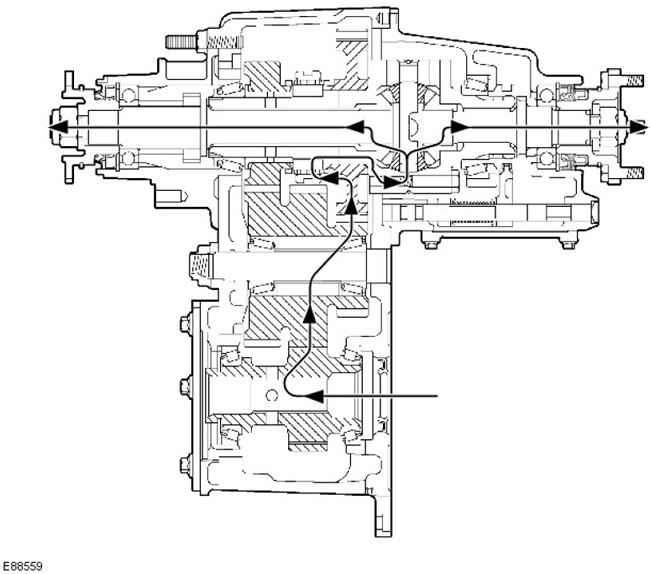

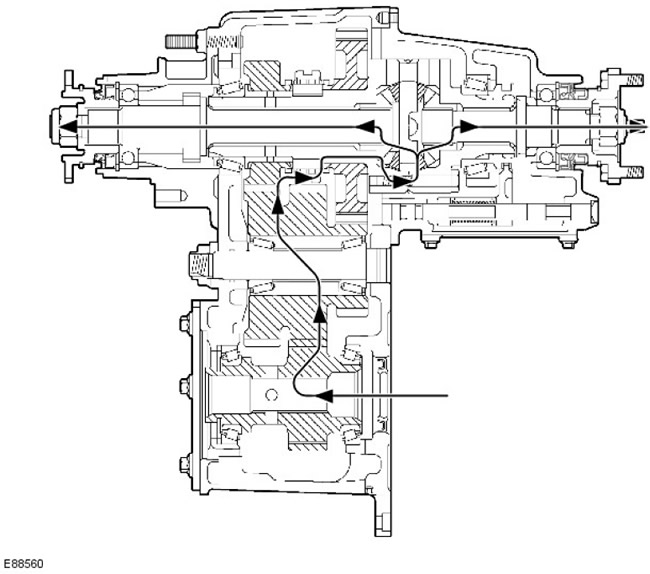

Job

Power flow - transfer case in LOW range

Power flow - transfer case in HIGH range

The transmission drive shaft transmits power to the output shaft drive gear, which is in constant mesh with one of the intermediate gears. The intermediate gears are in constant mesh with the high and low range output gears, which are located on the rear differential shaft.

Power is transferred to the drive shafts through the differential assembly by locking the high or low range gears against the rear differential shaft. This is achieved through the fork, bushing and splined hub of the high/low range selector.

Comments on this article