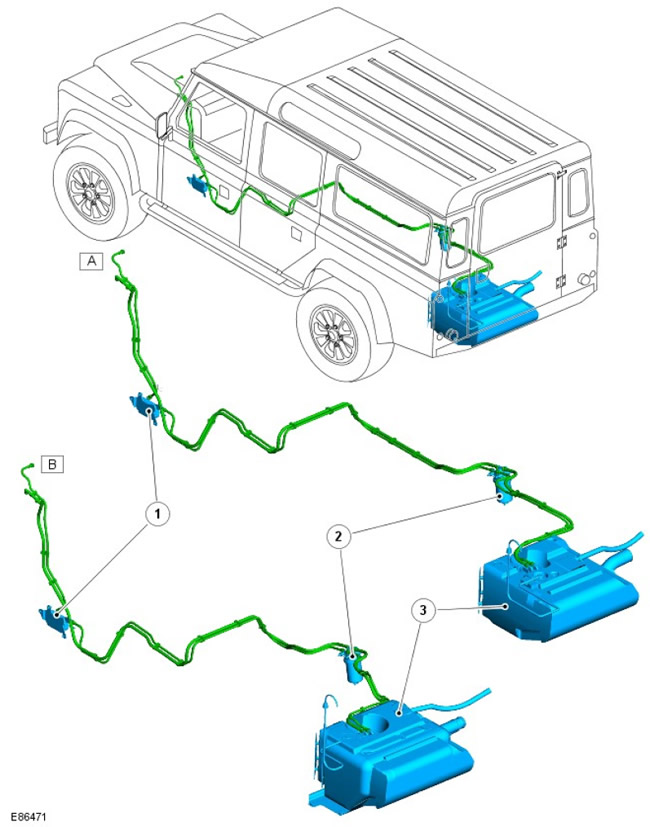

Location of elements

| Pos. | spare part no | Name |

| A | - | Option 110 |

| B | - | Option 90 |

| 1 | - | Fuel System Radiator |

| 2 | - | Fuel filter |

| 3 | - | Fuel tank |

Review

The fuel supply system includes a filler pipe and a flexible pipe, a fuel tank (including sensor assembly and ventilation system), fuel filter, fuel cooler, bleed valve and connecting fuel lines.

The fuel system supplies fuel to the engine through a booster pump, which is an important part of the injection pump built into the engine. The fuel system is a rarefied system with a pressure drop across the transfer pump of 20-30 kPa.

The return flow from the engine is returned to the filter. To prevent waxing of the filter at low temperatures, a thermostatic diverter directs the heated return flow back through the filter to the engine. At higher temperatures, the return flow is diverted back to the tank.

Fuel filler neck with cap

The fuel filler is located on the panel in the right rear quarter, behind the hatch. The hatch is opened by an electrical switch on the dashboard that controls the releasing solenoid.

The filler hole is closed with a plastic cap on the thread, screwed onto its neck. The cap is equipped with a ratchet to prevent over tightening and seals the filler cap to prevent fuel vapors from escaping. The filler cap has a valve that releases excess fuel pressure to atmosphere at about 0.12 - 0.13 bar and opens in the opposite direction at about 0.04 bar.

The fill port is connected to the fuel tank by a molded flexible high density polyethylene hose (HDPE).

Fuel tank

The fuel tank is located at the rear of the car from below, between the chassis side members.

The support is attached to the chassis with six screws. When the leg is attached to the chassis, the tank is protected by foam pads adjacent to the center cross member of the chassis. Additional protection is provided by a protective cover, which is installed in the front right corner of the tank.

The fuel tank is made of HDPE. The fuel tank is a sealed unit with the only internal access possible through a hole in the flange of the fuel pump module located at the top of the tank.

The reflective metal coating is attached to the tank with two threaded rivets and serves to protect the tank from heat generated in the exhaust system.

Possible fuel tank capacities

| Option | Fuel tank capacity |

| 90 | 56 l |

| 110 | 70 l |

Fuel tank ventilation system

A ventilation system is provided in the filler pipe, due to which air and fuel vapors are forced out of the tank during refueling and discharged into the atmosphere through the filler neck.

The breather outlet in the tank serves to control the height "full filling" tank. When the fuel closes the outlet, fuel vapor and air from the tank is blocked from escaping. As a result of this, there "backfill" fuel filler pipe and fuel nozzle cut-off. The location of the outlet is such that when the fuel nozzle is turned off, the space for fuel vapors is approximately 10% of the total tank capacity. Thanks to the organization of the vapor space, the ROPS valve (ROV) is always above the fuel level, so vapors can escape and vent the tank.

The ROV is welded to the top surface of the tank. The ROV is connected to a ventilation duct to the atmosphere. The ROV allows fuel vapor to pass through under normal vehicle operating conditions. In the event of a vehicle rollover, the valve closes, ensuring the tightness of the tank and preventing fuel from pouring through the ventilation pipe into the atmosphere.

The vent line to the atmosphere includes a two-way valve that allows one-way depressurization and air inflow into the tank when the system is operating under vacuum conditions.

Fuel level sensor

The fuel gauge sensor is located inside the fuel tank. The sensor assembly is accessed through an opening in the top of the tank. The block flange is fixed in working position and sealed with a steel retaining ring.

The fuel sensor assembly includes a top cover flange that contains an electrical connector for connecting the sensor and two steel fuel line connections.

The flange is sealed with a rubber seal installed between this flange and the circlip housing.

The top cover is attached to the swirl chamber assembly with two spring-loaded steel posts. Springs securely fix the vortex chamber at the bottom of the tank.

The vortex chamber ends with a cavity in which the fuel gauge sensor is located.

The vortex chamber plays the role of fuel storage by ensuring that the fuel intake is always below the fuel level. This is achieved by means of a reverse flow directed into the vortex chamber, and the jet pump provides an additional flow into the chamber, formed by the fuel remaining in the tank, and the operation of the jet pump is provided by the reverse flow. In addition, a bypass valve is located at the base of the vortex chamber assembly. When the fuel tank is full, fuel pressure keeps the valve lifted off the seat and fuel can flow into the swirl chamber. As the fuel level in the tank decreases, the fuel pressure in the tank drops and the valve closes as a result. When the valve is closed, the fuel is held in the swirl chamber.

Flexible conduits connected to the top cover provide fuel supply to and return from the vortex chamber.

The fuel gauge sensor is equipped with a potentiometer that operates with a float element.. The float element rises and falls depending on the fuel level in the tank and moves the potentiometer accordingly.

The voltage to the potentiometer is supplied from the instrument panel. The output resistance of the potentiometer changes depending on the fuel level. This resistance is displayed on the instrument panel using the fuel gauge.

The signaling device mounted on the instrument panel turns on when the amount of fuel in the tank drops to 10 liters.

ROPS valves (ROV)

Two ROVs are located on the fuel tank support structure and are piped to the fuel vapor separator. The phase separator, also mounted on the inner bracket, is connected by a tube to the fuel tank ventilation fitting on the fuel priming pump flange. ROV valves contain check valves that close when the vehicle rolls over, preventing liquid fuel from leaking from the tank through the breather tube.

Fuel fine filter

The fuel filter removes particulate matter from the fuel and also separates water that accumulates at the bottom of the filter.

The fuel filter is located on the chassis to the right of the fuel tank. The fuel supplied to the engine and returned from the engine passes through the filter. Connections are made using quick connectors.

The rear steel cover is attached to the chassis side member with four M8 threaded screws.

The filter is screwed to the mounting plate with two M8 threaded bolts.

The steel protective cover is fixed on the back cover with a special lock with a 1/4 turn.

The filter is equipped with an internal air bleeder that ensures that only small, controlled amounts of air enter the engine along with the fuel.

The thermostatic diverter valve is fully closed at 45 degrees Celsius and directs fuel directly to the tank. When the diverter is open, the fuel is recirculated through the filter to the engine.

The fuel filter is equipped with a replaceable cartridge-type filter element with a threaded fastening, which is sealed relative to the filter housing with rubber seals. The bottom section of the cartridge is equipped with a threaded tip for draining water.

Cartridge life before replacement is 24,000 miles.

In countries where poor quality fuel is used, cartridge life may be shortened.

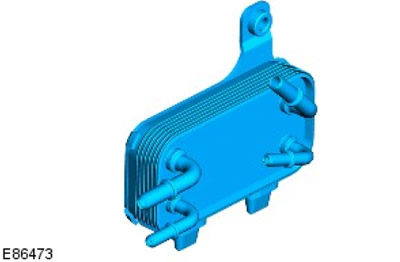

Fuel cooler

The fuel cooler uses the coolant coming from the radiator to reduce the temperature of the fuel returning to the tank from the high pressure fuel pump.

The cooler is fixed on the bracket, which, in turn, is mounted on the inner left rail of the chassis. The bracket has two slots into which the plastic protrusions of the cooler body are inserted. The cooler is attached to the bracket with an M8 threaded bolt.

The cooler is equipped with four quick connectors. Fuel inlet and outlet; supply and return of coolant.

Air release valve

The air release valve is located on the fuel line near the injection pump. It facilitates connecting to a vacuum when filling the fuel system and removing air during refueling. This helps to protect the injection pump from air locks.

Fuel lines

The three fuel line assemblies form a connection that supplies and returns fuel from the tank to the filter, from the filter to the cooler, and from the cooler to the engine.

These fuel lines consist of conductive nylon with a wall thickness of 1mm, coated with 2mm thick refractory Santoprene and with an anti-abrasion coating. The diameter of the supply fuel line is always greater than the diameter of the return line.

Low fuel indication and strategy "run-dry"

Strategy "run-dry" used to maintain the fill level of the fuel system close to its fuel depletion conditions. It ensures that the minimum amount of fuel always remains in the swirl chamber.

The yellow warning light on the instrument panel indicates a low fuel level (next to the fuel gauge), that is, that no more than 15% of it remains in the tank. The fuel gauge indicates that the tank is empty when there is still 11% of fuel left in the tank.

When 4 liters of fuel remain in the tank, the strategy is initiated "run-dry". Engine misfiring occurs after about 1 mile (1.6 km), after which the engine stops. The engine can be restarted in misfire mode and will continue to run for another mile until the engine stalls again. This can be repeated until the inlet in the tank appears above the fuel level, causing the engine to experience fuel starvation and a permanent loss of power. Restarts after stops in driving mode "run-dry" are not recommended.

Comments on this article