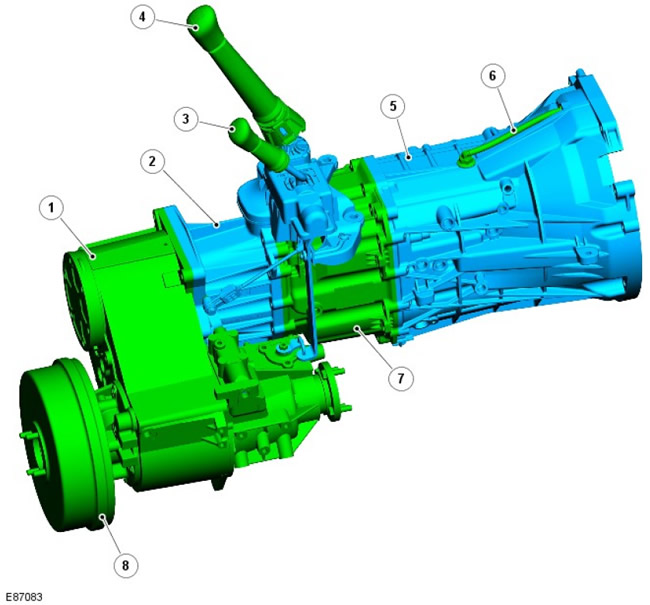

Location of elements

| Pos. | spare part no | Name |

| 1 | - | Transfer box assy |

| 2 | - | Transmission case extension |

| 3 | - | Transfer case selector lever |

| 4 | - | Gear selector |

| 5 | - | Frontal gearbox housing |

| 6 | - | Ventilation piping |

| 7 | - | gearbox housing |

| 8 | - | Gearbox parking brake |

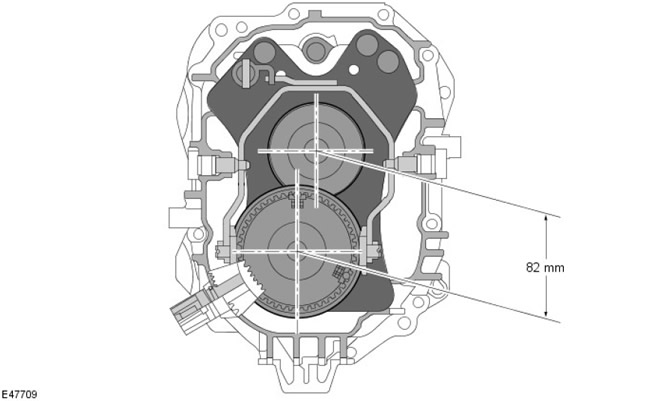

Review

The MT82 manual transmission has six forward gears and a reverse gear. It is installed along the longitudinal axis of the car, and its maximum torque is 360 Nm. The cast aluminum gearbox housing is bolted to the transfer case via a cast aluminum extension.

The 6th gear ratio has been chosen to improve economy and comfort during fast driving. Optimal gear shifting ensures economical fuel consumption and efficient use of engine torque. Six-speed transmission provides a wide range of gear selection for improved economy and controllability (e.g. when maneuvering at low speed or when towing a trailer).

Name "MT82" reflects the distance between the two shafts in the gearbox:

- M - mechanical

- T - gearbox

- 82 - distance between two shafts in mm

The transmission is refueled for life and a service level check is not required unless a leak is found.

Technical data

|

Input torque |

gear ratios |

Dry weight |

Refueling oils |

Specification oils |

||||||

|

1st |

2nd |

3rd |

4th |

5th |

6th |

rear |

||||

|

360Nm |

5,441 |

2,840 |

1,721 |

1,223 |

1,00 |

0,742 |

4,935 |

50,8 kg |

2.4L |

WSD-M2C200-C |

In 5th gear, the input and output shafts are directly connected to each other. In this case, a gear ratio of 1:1 takes place.

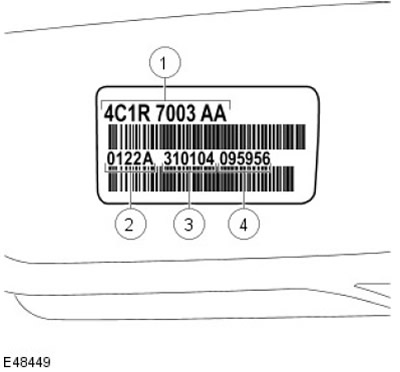

Model plate

| Pos. | spare part no | Name |

| 1 | - | Spare part number |

| 2 | - | Place of manufacture (Halewood) |

| 3 | - | Vehicle manufacture date |

| 4 | - | Preparation time |

Rating plate on the right side of the gearbox in the area of the output flange for attaching the cardan shaft.

It is for the sole purpose of identifying the transmission. All orders for spare parts are subsequently carried out using the vehicle identification number (VIN).

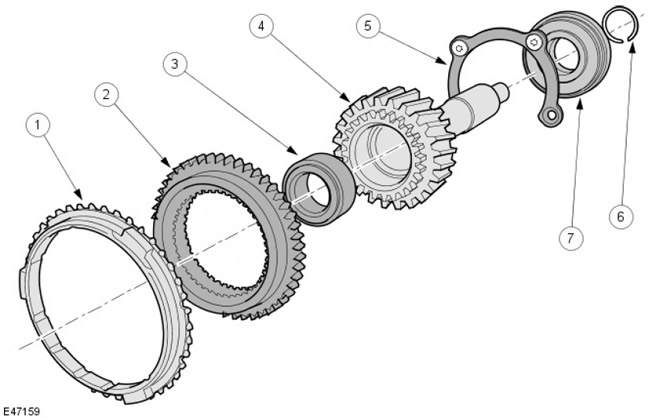

Input shaft

| Pos. | spare part no | Name |

| 1 | - | 5th gear synchronizer snap ring |

| 2 | - | 5th gear synchronizer ring gear |

| 3 | - | Output shaft guide bearing |

| 4 | - | input shaft |

| 5 | - | Bearing retainer plate |

| 6 | - | ball bearing circlip |

| 7 | - | Main shaft ball bearing |

The input shaft is movably connected to the output shaft through a guide bearing (3). To absorb axial forces input shaft ball bearing (7) has additional protection.

All input shaft components can be serviced individually.

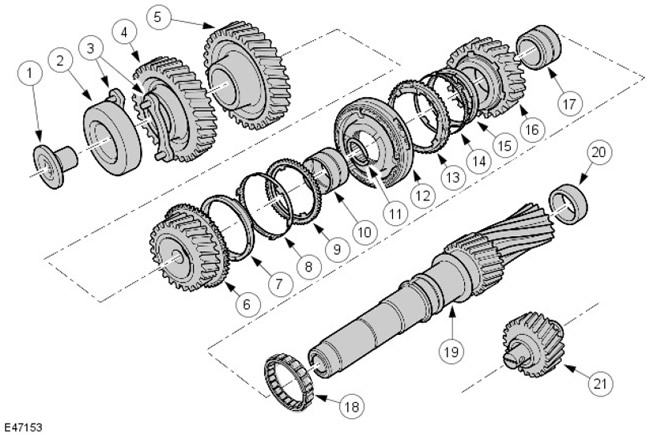

Intermediate shaft

| Pos. | spare part no | Name |

| 1 | - | Mounting bolt |

| 2 | - | Intermediate shaft ball bearing |

| 3 | - | Bearing retainer plate |

| 4 | - | intermediate shaft drive gear |

| 5 | - | Driven gear 6th gear |

| 6 | - | Third gear gear |

| 7 | - | Synchronizer cone 3rd gear |

| 8 | - | Synchronizer inner ring |

| 9 | - | Synchronizer outer ring 3rd gear |

| 10 | - | Needle roller bearing |

| 11 | - | Retaining ring |

| 12 | - | Coupling of the synchronizer of the third and fourth transfers assy |

| 13 | - | Synchronizer outer ring 4th gear |

| 14 | - | Synchronizer inner ring |

| 15 | - | Synchronizer cone 4th gear |

| 16 | - | 4th gear |

| 17 | - | Needle roller bearing |

| 18 | - | Central intermediate shaft bearing |

| 19 | - | intermediate shaft |

| 20 | - | Roller bearing intermediate shaft |

| 21 | - | Reverse intermediate gear |

The intermediate shaft transmits torque from the input shaft to the secondary. The drive and driven gears are located on the shaft, as well as the 3rd/4th gear synchronizer clutch. Gear wheels of 1st and 2nd gears and reverse gears are non-removable.

The countershaft drive and driven gears can be replaced separately. Improved manufacturing tolerances eliminate the need to replace pairs of gears.

The intermediate shaft is solid. To prevent axial movement of the shaft, it is additionally fixed with a bolt (1) and bearing retainer plate (3).

The direction of rotation of the output shaft is changed by means of the intermediate gear of the reverse gear (21).

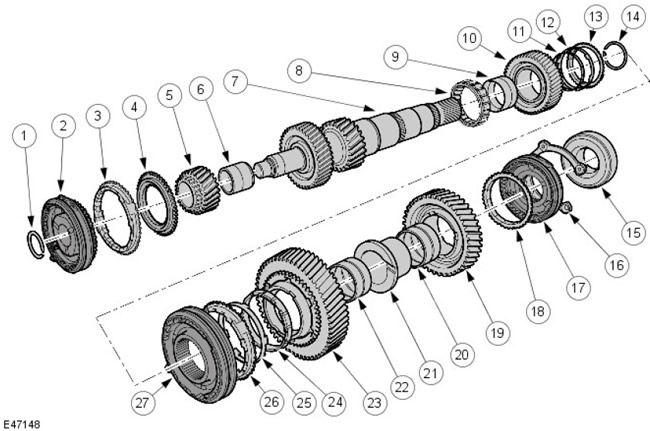

Output shaft

| Pos. | spare part no | Name |

| 1 | - | Retaining ring |

| 2 | - | 5th/6th gear synchronizer clutch |

| 3 | - | Lock ring of the synchronizer of 6th transfer |

| 4 | - | 6th gear synchronizer ring gear |

| 5 | - | Drive gear 6th gear |

| 6 | - | Needle roller bearing |

| 7 | - | output shaft |

| 8 | - | Secondary shaft intermediate bearing |

| 9 | - | Needle roller bearing |

| 10 | - | Drive gear 2nd gear |

| 11 | - | Synchronizer cone 2nd gear |

| 12 | - | Synchronizer inner ring |

| 13 | - | Synchronizer outer ring 2nd gear |

| 14 | - | Retaining ring |

| 15 | - | Secondary shaft ball bearing |

| 16 | - | Bearing retainer plate |

| 17 | - | Reverse Synchro Clutch |

| 18 | - | Reverse synchro lock ring |

| 19 | - | Reverse drive gear |

| 20 | - | Needle roller bearing |

| 21 | - | Needle roller bearing inner race |

| 22 | - | Needle roller bearing |

| 23 | - | Drive gear of the first gear |

| 24 | - | Cone synchronizer 1st gear |

| 25 | - | Synchronizer inner ring 1st gear |

| 26 | - | Synchronizer outer ring 1st gear |

| 27 | - | 1st/2nd gear synchronizer clutch |

The rotation of the output shaft is transmitted through the output flange to an extension shaft connected to the transfer case. The 1st, 2nd and 6th gears, as well as the reverse gear, are located on the output shaft. The gears of the 3rd and 4th gears on the secondary shaft are non-removable.

By analogy with the input shaft, the 6th gear drive gear has a mounted synchronizer ring gear (4). It provides torque transmission when the 6th gear is engaged.

The output shaft drive and driven gears can be replaced separately.

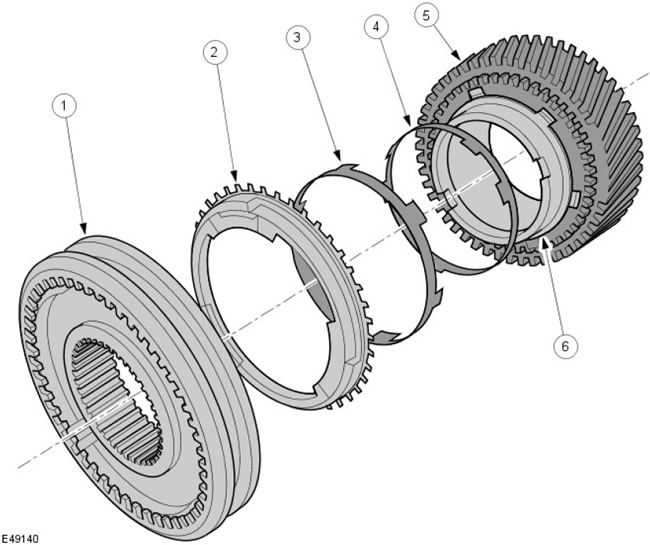

Triple synchronizer assembly

| Pos. | spare part no | Name |

| 1 | - | 1st/2nd gear synchronizer clutch |

| 2 | - | Synchronizer outer ring |

| 3 | - | Synchronizer inner ring |

| 4 | - | Synchronizer cone |

| 5 | - | Driven gear |

| 6 | - | Cone surface |

The synchronizer assembly has three friction surfaces. Due to the additional conical surface (6) the total friction surface with triple synchronization increases significantly. This allows you to reduce the required shift effort into 1st and 2nd gear.

Since the tapered surface is part of the drive gear, no additional synchronizer ring is required.

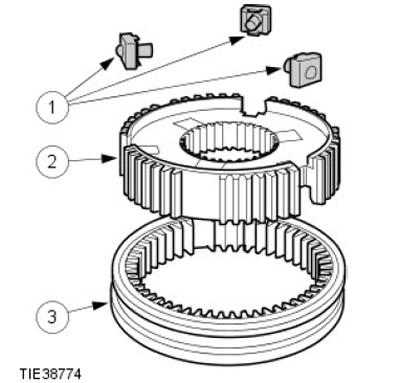

Synchronizer assembly

| Pos. | spare part no | Name |

| 1 | - | Carriage assembly |

| 2 | - | Synchronizer hub |

| 3 | - | Sliding Synchronizer Clutch |

The pressure springs and fixing balls of the carriage are combined into one unit.

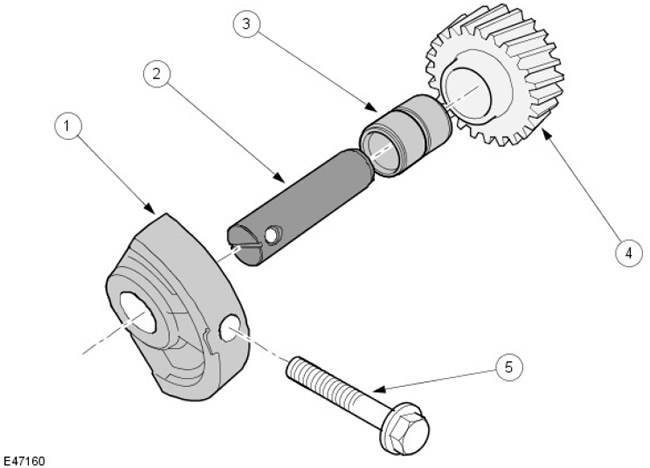

Reverse intermediate gear

| Pos. | spare part no | Name |

| 1 | - | support bracket |

| 2 | - | Reverse intermediate gear shaft |

| 3 | - | Needle roller bearing |

| 4 | - | Reverse intermediate gear |

| 5 | - | Bolt of fastening of a basic arm of transfer of a backing |

With the help of an intermediate reverse gear, a change in the direction of rotation of the output shaft is ensured. The reverse idler gear is fitted with a needle roller bearing mounted on the idler gear shaft. The axle is mounted in the support bracket (1) and reciprocal hole of the gearbox housing.

To absorb radial forces, the reverse idler gear is additionally located on the support bracket.

If the reverse gear can be replaced separately.

Comments on this article