Special tool (s)

| Assembly Tool, Bearing Cup/Front Wheel Hub Seal 204-087 |

| Puller, bearing/pinion 205-310 |

| Mounting bracket, engine/diff 205-329 |

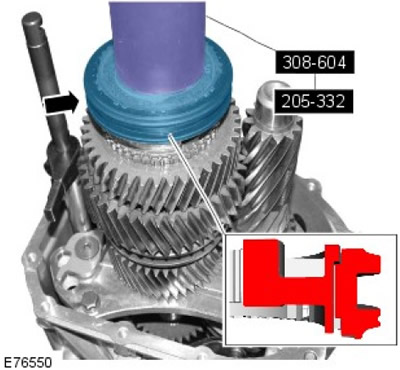

| Protection, axle shaft 205-332 |

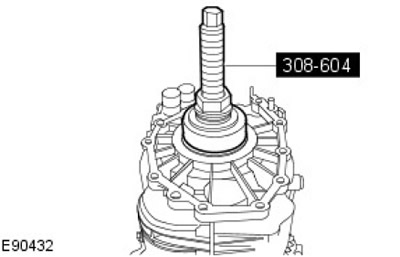

| Mounting Tool, Secondary Drive Flange Seal 308-604 |

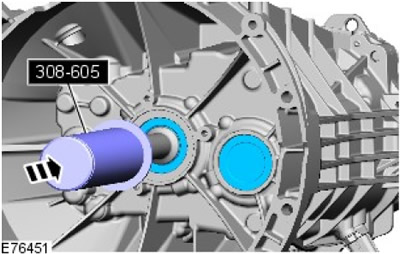

| Assembly tool, input shaft seal 308-605 |

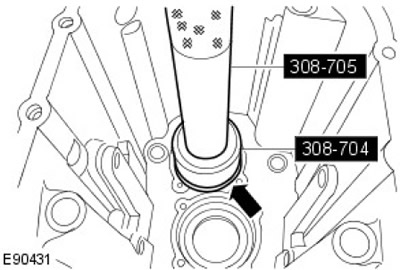

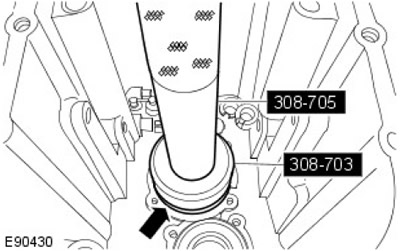

| Handle, mounting tool for bearings 308-705 |

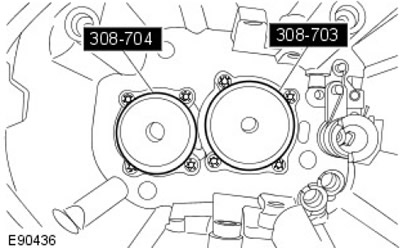

| Mounting Tool, Countershaft Bearing 308-704 |

| Mounting Tool, input shaft bearing 308-703 |

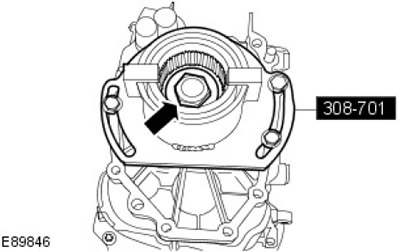

| Mounting Tool, output shaft bearing 308-702 |

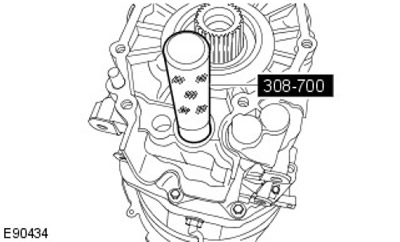

| Mounting Tool, Select Shaft Seal 308-700 |

General Equipment

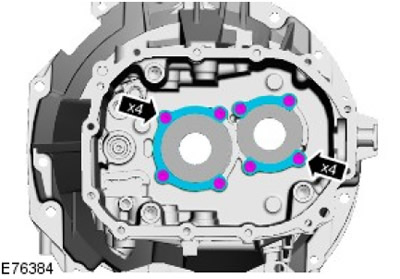

- Clamps

- hot air hot air gun

- Hydraulic Press

Materials

| Name | Specification |

| transmission fluid | WSD-M2C200-C |

| High temperature grease | ESD-M1C220-A |

| sealant | WSK-M2G348-A5 |

| Adhesive - Loctite 243 | WSK-M2G349-A7 |

Assembly

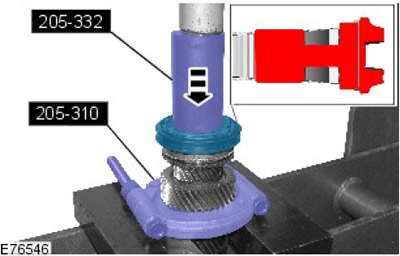

1.

NOTE: Lubricate all synchronizer rings and needle bearings with clean gear oil before reassembly.

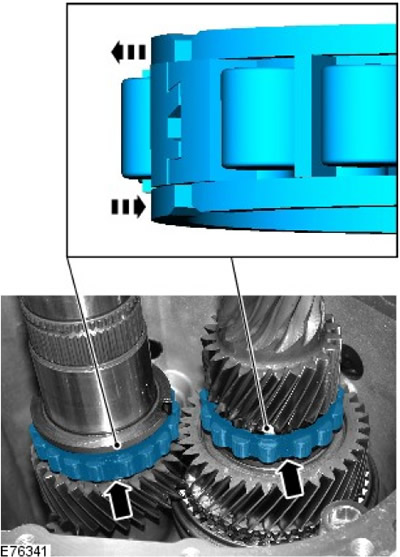

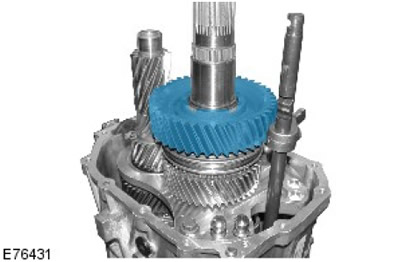

2. Install the 4th gear and the 3rd/4th gear synchronizer assembly onto the countershaft.

3. Install the 3rd/4th gear synchronizer retaining ring assembly onto the intermediate shaft. Install a new snap ring.

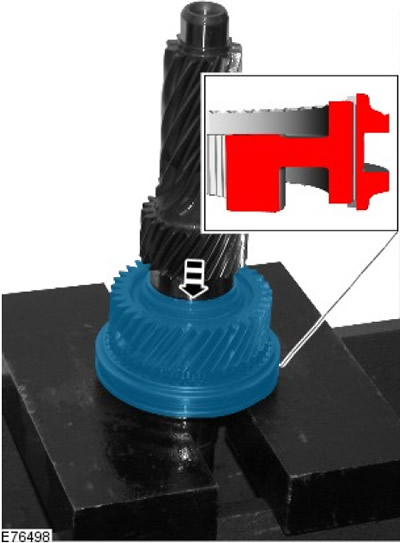

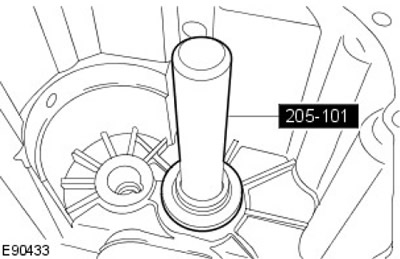

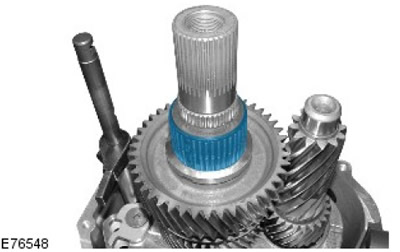

4. Using the special tool, install the 6th gear on the countershaft.

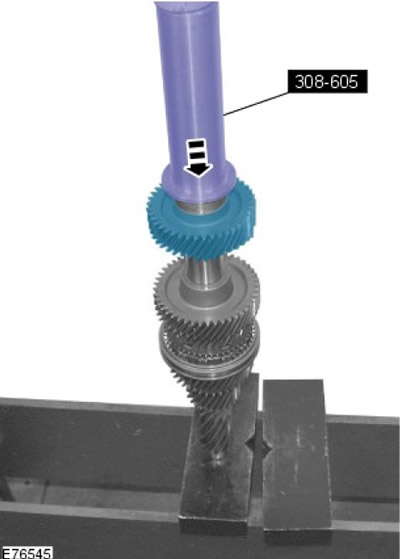

5. Using special tools, install 5th gear.

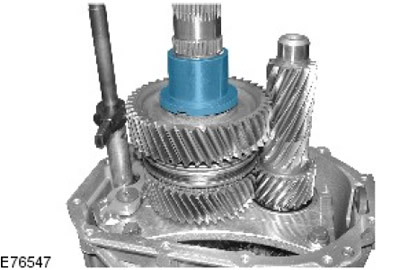

6. Using the special tools, install the 5th/6th gear synchronizer assembly onto the output shaft.

7.

WARNING: Be careful when using the fan heater. Failure to follow this instruction may result in injury.

NOTE: Heat the gearbox housing to approximately 100°C with a thermal fan.

Using the special tool, install the intermediate shaft bearing outer raceway into the transmission housing.

8.

WARNING: Be careful when using the fan heater. Failure to follow this instruction may result in injury.

NOTE: Heat the gearbox housing to approximately 100°C with a thermal fan.

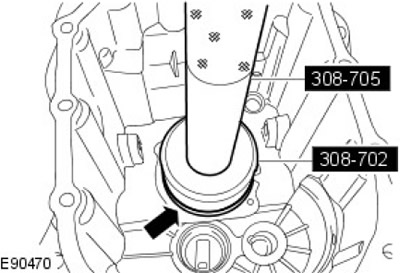

Using the special tools, install the output shaft bearing.

9. Establish a lock lath of a secondary shaft. Tighten the bolts to 10 Nm.

10.

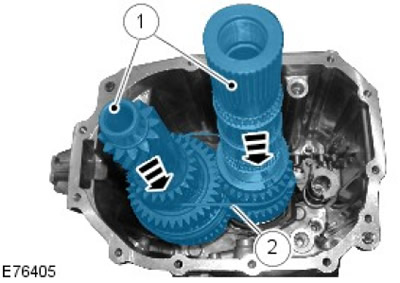

NOTE: Install the assemblies in the position marked when removed.

Install the components in the gearbox housing as follows.

- 1. Roller bearing of the intermediate shaft.

- 2. Intermediate reverse gear.

- 3. Fastening of an intermediate gear wheel of a backing.

- 4. Tighten the bolt (tightening torque 27 Nm).

11.

WARNING: Be careful when using the fan heater. Failure to follow this instruction may result in injury.

NOTE: Heat the gearbox housing to approximately 100°C with a thermal fan.

Using the special tool, install the countershaft bearing.

12.

WARNING: Be careful when using the fan heater. Failure to follow this instruction may result in injury.

NOTE: Heat the gearbox housing to approximately 100°C with a thermal fan.

Using the special tools, install the input shaft bearing.

13. Install the bearing retainers. Tighten the bolts to 10 Nm.

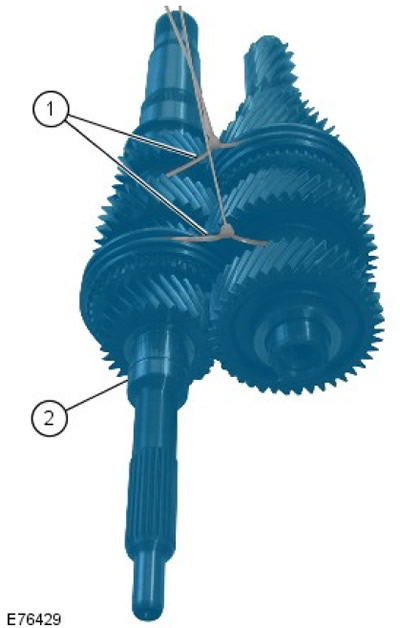

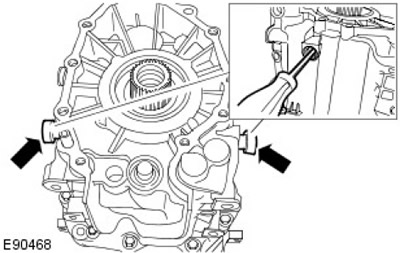

14. Connect shaft assemblies.

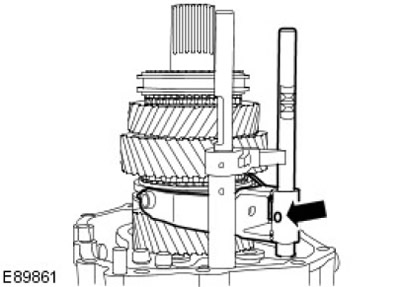

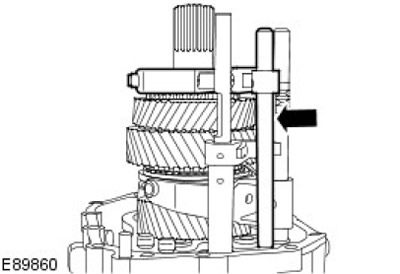

- 1. Install suitable clamps at the indicated points.

- 2. Make sure the input shaft has not come loose.

15.

WARNING: Be careful when using the fan heater. Failure to follow this instruction may result in injury.

NOTE: Heat the special tools with a fan heater to approximately 100°C and transfer them to the bearings.

Using special tools, heat the middle bearing races.

16. Establish knots of secondary and intermediate shaft. Remove and discard clamps.

17. Install the 3rd/4th and 5th/6th gear selectors. Tighten the bolts to 37 Nm.

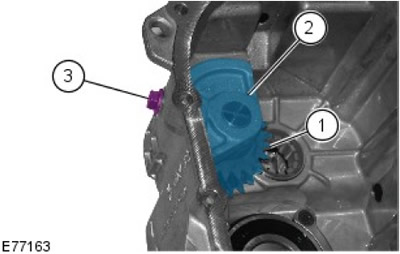

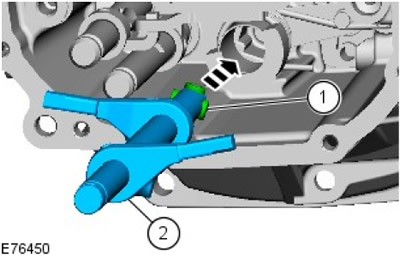

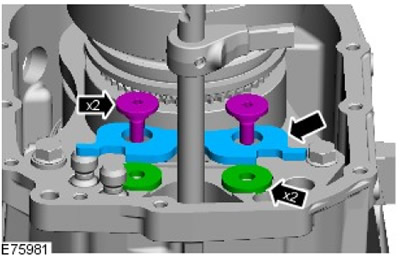

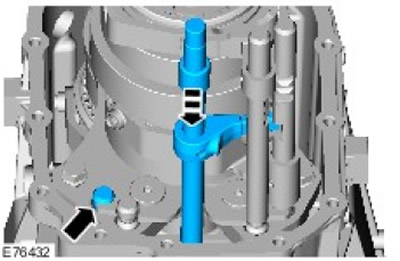

18. Install the main selector.

- 1. Apply grease to the bearings. Grease

- 2. Install the main selector.

19. Install the center bearings.

20. Install the center bearing mounting plate. Tighten the bolts (tightening torque 24 Nm).

21. Establish a lock lath of a shaft of a choice of transfers.

- Install spacers.

- Tighten the bolts (tightening torque 24 Nm).

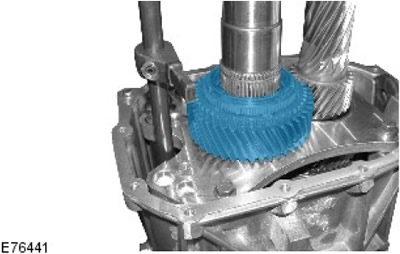

22. Install 2nd gear and bearing on output shaft.

23. Using the special tools, install the 1st/2nd gear synchronizer assembly onto the output shaft.

24. Install the 1st/2nd gear synchronizer snap ring. Install a new snap ring.

25. Install the 1st gear needle bearing.

26. Set 1st gear.

27.

WARNING: Be careful when using the fan heater. Failure to follow this instruction may result in injury.

NOTE: Heat the reverse bearing inner race to approximately 100°C with a thermal fan.

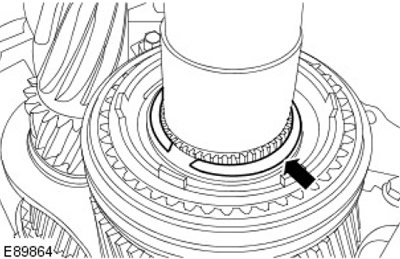

Install the reverse bearing inner race.

28. Install the reverse gear needle bearing.

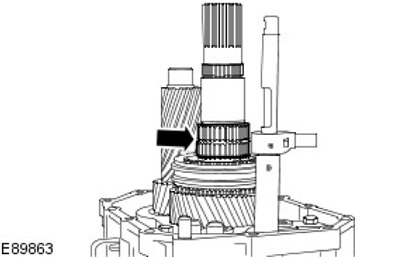

29. Install the reverse gear on the secondary shaft.

30. Using the special tool, install the reverse gear synchronizer on the output shaft.

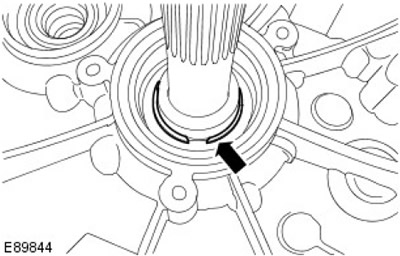

31. Install the 1st/2nd gear selector. Install a new pin.

32. Install the reverse gear selector.

33. Select a gear.

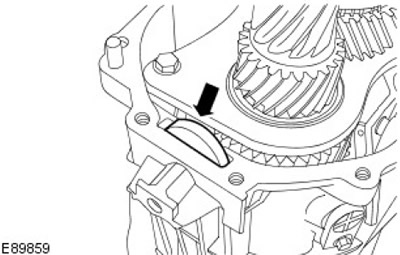

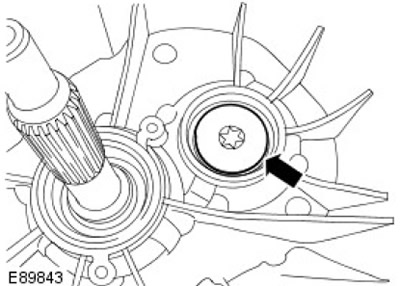

34. Install the magnet.

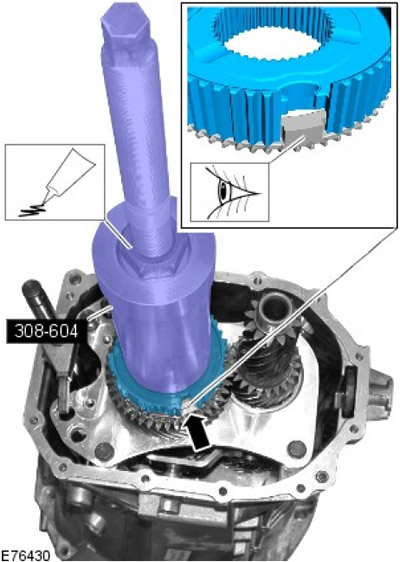

35.

WARNING: Be careful when using the fan heater. Failure to follow this instruction may result in injury.

NOTE: Heat the special tool with a fan heater to approximately 100°C and transfer it to the bearing.

Using the special tool, heat the bearing inner race.

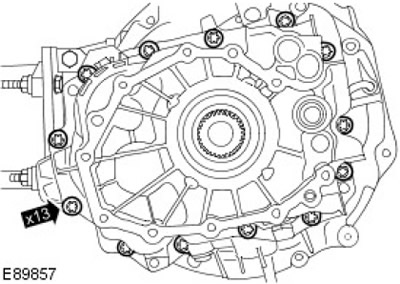

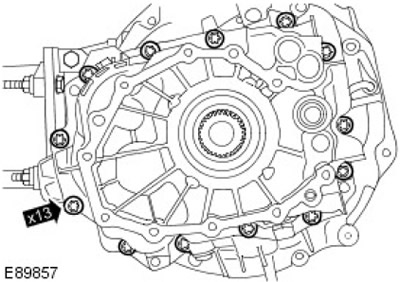

36. Install the gearbox housing.

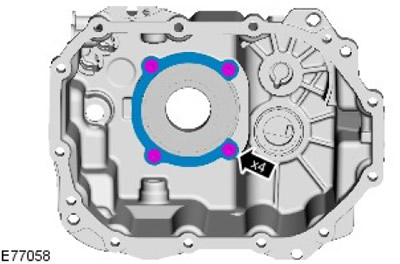

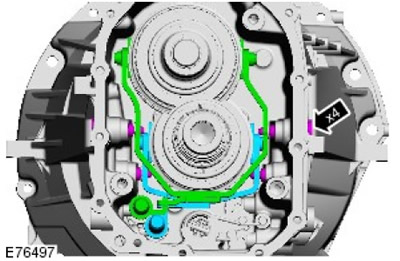

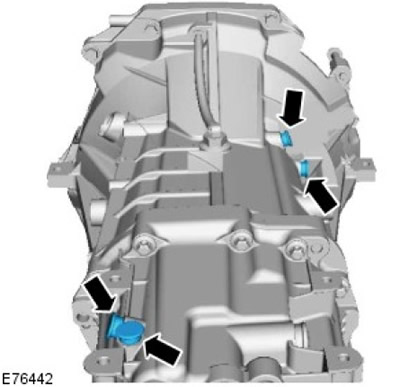

- Apply sealant to mating surfaces. sealant

- Install but do not tighten the gearbox housing bolts.

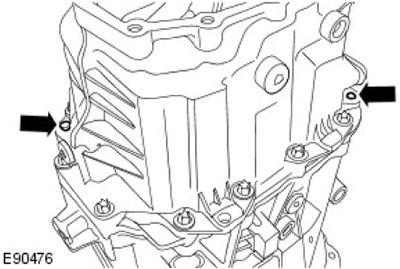

37. Establish bolts of fastening of a plug of the selector of a reverse gear.

- Align the selector fork.

- Tighten (tightening torque 37 Nm).

38. Tighten the gearbox housing bolts in a cross pattern. Tighten (tightening torque 24 Nm).

39. Reinstall dowel pins.

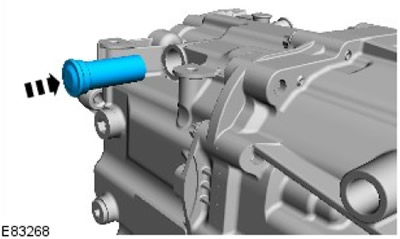

40. Establish new stoppers of a shaft of a choice of transfers.

41. Move the main shaft of a choice of transfers to neutral position.

42. Install a new gear select shaft retainer.

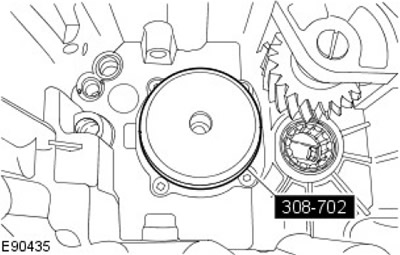

43. Using the special tools, install the gear selector main shaft oil seal.

44. Establish an epiploon of a secondary shaft of a transmission.

45.

WARNING: Be careful when using the fan heater. Failure to follow this instruction may result in injury.

NOTE: Heat the transmission output flange to approximately 100°C using a fan heater.

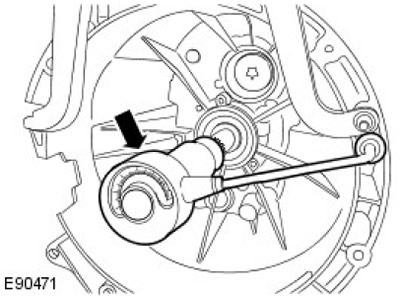

Using the special tools, install the transmission output flange.

- tighten bolt (tightening torque 210 Nm).

- Loosen the bolt.

- Apply threadlocker.glue

- tighten bolt (tightening torque 180 Nm).

46.

NOTE: Make sure transmission is enabled.

Install the intermediate shaft fixing bolt. Tighten (tightening torque 95 Nm).

47. Install the input shaft circlip. Install a new snap ring.

48. Turn the gearbox shafts and check the operation of all gears.

49. Using a suitable tool, check the torque first in neutral by blocking the output flange. Maximum torque 1.2 Nm.

50. Using the special tool, install the oil seals of the primary and intermediate shafts of the gearbox.

51. Remove the gearbox from the stand.

52.

WARNING: It is forbidden to carry out work on a vehicle standing on only one jack. Always support the vehicle with jack stands.

Raise the car and place stands under it.

53. Install the gearbox in the block with the drive axle.

For more information, see the chapter: Gearbox (308-03 Manual transmission / transmission in a block with a driving axle, Removal).

54. Fill the gearbox with oil.

For more information, refer to the chapter: Draining the transmission fluid from the gearbox and filling the transmission fluid into the gearbox (308-03 Manual/Transaxle Transmission, General Procedures).

55. Connect the wire "masses" to the battery.

For more information, see the chapter: Connecting the Battery (414-01 Battery, Battery Mount and Wires, General Procedures).

Comments on this article