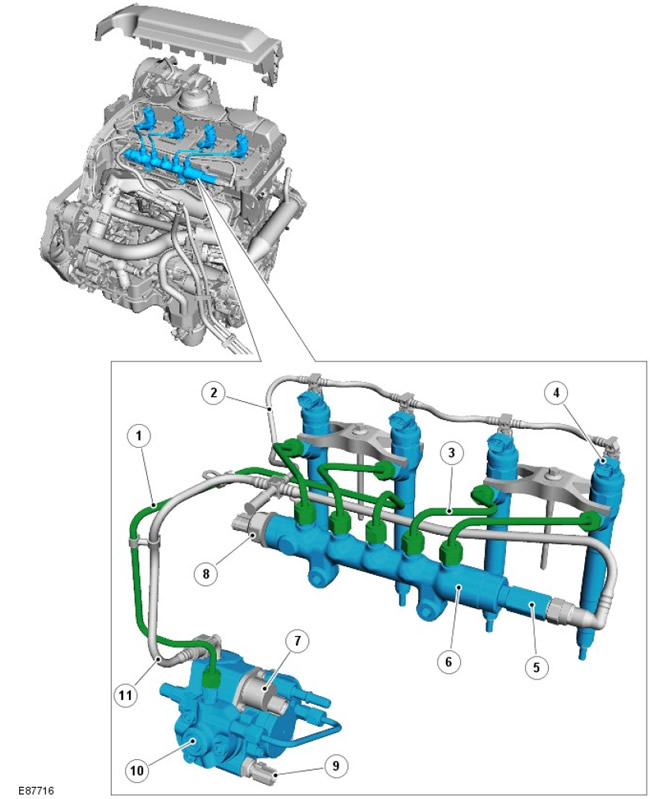

Location of elements

| Pos. | spare part no | Name |

| 1 | - | High pressure fuel line |

| 2 | - | Drain fuel line |

| 3 | - | High pressure fuel line |

| 4 | - | Fuel burner |

| 5 | - | Pressure limiting valve |

| 6 | - | fuel manifold |

| 7 | - | Pump capacity regulator (VCV) |

| 8 | - | Fuel pressure sensor |

| 9 | - | Fuel temperature sensor |

| 10 | - | High pressure fuel pump |

| 11 | - | Fuel return line |

Review

2.4L diesel engine equipped with high pressure fuel injection system (battery type). With this fuel injection process, the injection pump creates a uniform pressure in the shared lines (common rail system), that serve all 4 fuel injectors. The pressure in the fuel manifolds is maintained at an optimum level for smooth operation and can reach 1600 bar.

The system provides two-phase injection (preliminary and main phases), which reduces the noise of the working process and the mechanical load on engine parts.

Fuel injection pressure is generated regardless of engine speed and fuel injection occurrences. Fuel injection timing and fuel volume are calculated by the engine control unit (ECM), which then activates the corresponding injector solenoid.

The common rail fuel injection system has the following features:

- High fuel injection pressures up to 1600 bar for better fuel atomization (which improves performance and reduces exhaust emissions)

- Independent regulation of injection parameters for cylinders ensures optimal combustion in all modes

- Low tolerances and high accuracy throughout the life of the system

The fuel supply system consists of two circuits:

- Low pressure system

- High pressure system

The low pressure circuit includes the following components:

- Low pressure pump (located inside the high pressure pump)

- Fuel filter

- Fuel System Radiator

The high pressure circuit includes the following components:

- High pressure fuel pump

- fuel manifold

- High pressure fuel lines

- Injectors

Comments on this article