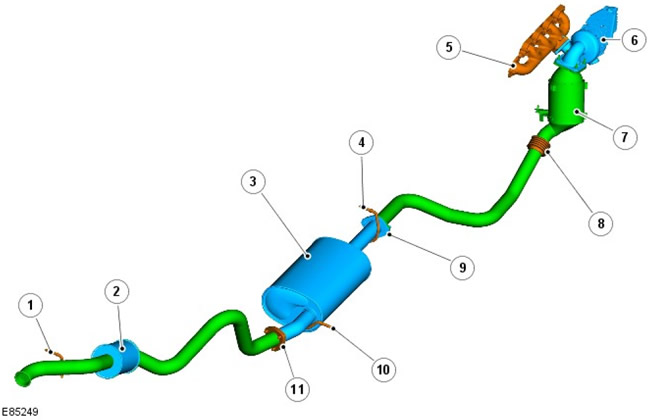

110 - Arrangement of elements

| Pos. | spare no | Name |

| 1 | parts | Rear hanging bracket |

| 2 | - | Rear silencer |

| 3 | - | Middle muffler |

| 4 | - | Front center suspension bracket |

| 5 | - | An exhaust manifold |

| 6 | - | Turbocharger (turbocharging) |

| 7 | - | Exhaust Catalytic Converter |

| 8 | - | flexible joint |

| 9 | - | Front hinge |

| 10 | - | Rear center hanger |

| 11 | - | Rear hinge |

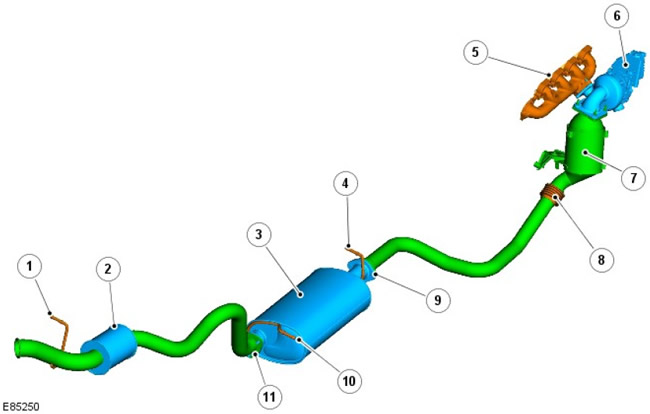

90 - Arrangement of elements

| Pos. | spare no | Name |

| 1 | parts | Rear hanging bracket |

| 2 | - | Rear silencer |

| 3 | - | Middle muffler |

| 4 | - | Front center suspension bracket |

| 5 | - | An exhaust manifold |

| 6 | - | Turbocharger (turbocharging) |

| 7 | - | Exhaust Catalytic Converter |

| 8 | - | flexible joint |

| 9 | - | Front hinge |

| 10 | - | Rear center hanger |

| 11 | - | Rear hinge |

Review

The exhaust system is made of stainless steel and consists of three separate units:

- Front includes catalytic converter

- In the central part - the central muffler

- At the rear - rear muffler

The exhaust system is attached to the underbody with three rubber mounts, which are located on mild steel hangers welded to the system. On the bottom of the body, rubber cushions are attached to hooks welded to the bottom.

Spare parts are available to repair the downpipe and crosspipe of the exhaust system. Embossed arrows indicate cut points for front section replacement. When using a spare section, the pipes in the places of the segments are connected using a sleeve with clamps.

Front section

A flange with four M10 studs for four mounting holes of the turbocharger flange is welded to the front section. There is also a bracket for connecting the two rear studs to the manifold; they are attached to the turbocharger with four M10 nuts.

The flange is welded to the inlet cone of the converter, which, in turn, is welded to the converter body. The outlet cone is welded to the bottom of the converter. The corner section of the exhaust pipe is welded to it. The outer diameter of the corner section and the outlet pipe is 60 mm, the wall thickness is 1.5 mm. The disconnect sleeve is welded between the corner section and the outlet.

The catalytic converter is attached to the engine using a support bracket with two M8 bolts.

The rear of the outlet flare fits into the center section and the free flange is mounted on two M10 studs. Two M10 nuts are used for fastening and sealing.

Central section

The central muffler is a 21.33 l absorption chamber (1302 inches3) with triple seam. Inside the muffler are baffles, perforated pipes and grade E fiberglass filters to reduce noise as exhaust gases pass through the muffler. Suspension bracket welded to the front of the muffler intake pipe (directed to the left) for fixing in a rubber support. A second suspension bracket is welded to the right rear of the muffler on the 90 and to the exhaust pipe on the 110/130. The outer diameter of the inlet and outlet pipes is 63.5 mm, the wall thickness of the pipes is 1.5 mm.

The central and rear sections are connected by a flange coupling. The three studs of the rear mounting flange fit into the three holes in the rear section and are secured with three M10 nuts.

Rear section of exhaust pipe

Model 90 has a 0.73 liter straight-through chamber in the rear section (44.55"3) with seam. Inlet pipe outer diameter 63.5 mm, wall thickness 1.5 mm, there is a flange for connection with the central section. Outlet pipe OD 70mm, wall thickness 1.2mm, rolled end provided for safety. On the left side, a bracket is welded to the exhaust pipe for attaching to a rubber support.

Models 110/130 have a 0.73 liter straight-through chamber in the rear section (44.55"3) with seam. Inlet pipe outer diameter 63.5 mm, wall thickness 1.5 mm, there is a flange for connection with the central section. Outlet pipe OD 63.5mm, wall thickness 1.2mm, rolled end provided for safety. On the left side, a bracket is welded to the exhaust pipe for attaching to a rubber support.

Comments on this article