- Turbocharger oil return line

- Oil pickup tube

- Oil pump

- Oil filter and oil cooler assembly

- Oil pressure sensor

- oil dipstick

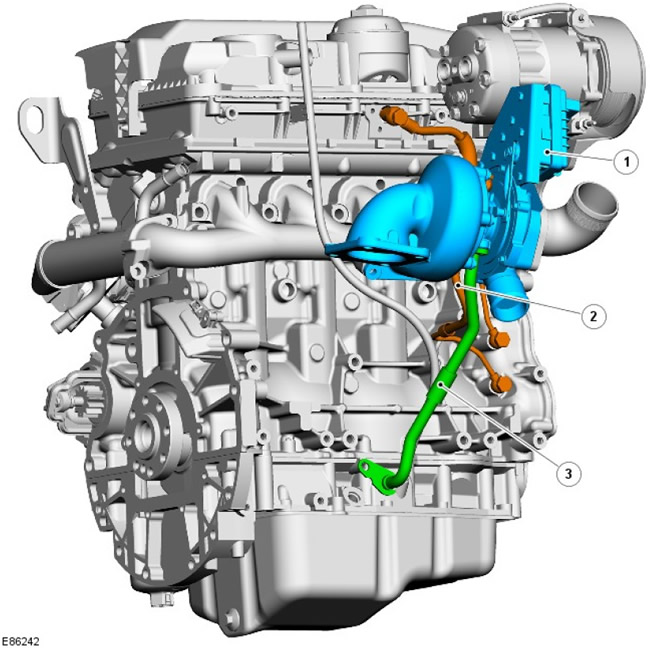

Oil return with turbocharger

| Pos. | spare part no | Name |

| 1 | - | Turbocharger assembly |

| 2 | - | Turbocharger oil supply line |

| 3 | - | Turbocharger oil return line |

To the tapered hole on the right at the front of the cylinder block, behind the alternator mounting bracket, via a connection type "banjo" the oil supply pipe to the turbocharger is connected. Thus, the turbocharger bearings are lubricated through the conical bore with high pressure oil generated by the oil pump.

On the left side of the ladder frame, under the turbocharger, there is a hole for the pipeline through which oil returns from the turbocharger to the sump.

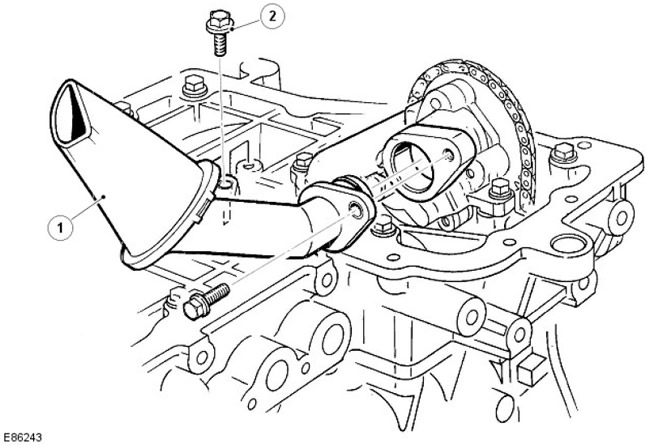

Oil receiver

| Pos. | spare part no | Name |

| 1 | - | Oil pickup tube |

| 2 | - | Bolt (2 pcs.) |

The weldable steel oil pick-up tube is immersed in a suitable recess in the oil pan and provides oil supply during all normal operating conditions. The inlet screen prevents foreign particles from entering the lubrication system.

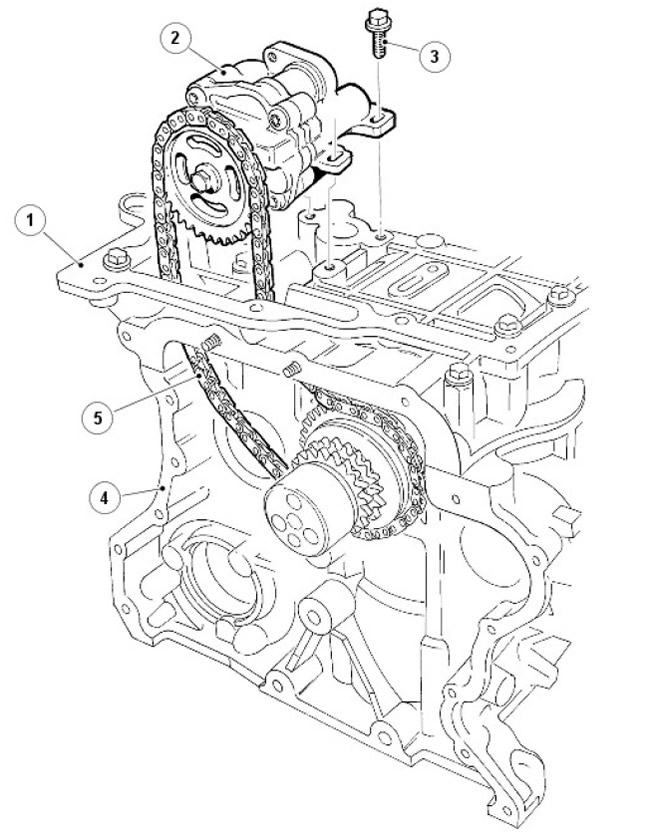

Oil pump

| Pos. | spare part no | Name |

| 1 | - | Stair construction |

| 2 | - | Bolt (4 things.) |

| 3 | - | Oil pump |

| 4 | - | Cylinder block |

| 5 | - | Oil pump drive chain |

The oil pump is located on the left front (from below) ladder frame and secured with 4 bolts. It is driven by a chain through the crankshaft sprocket. Oil is supplied to the pump from the main gallery through holes in the cylinder block.

The chain is tensioned and guided by a hydraulic chain tensioner.

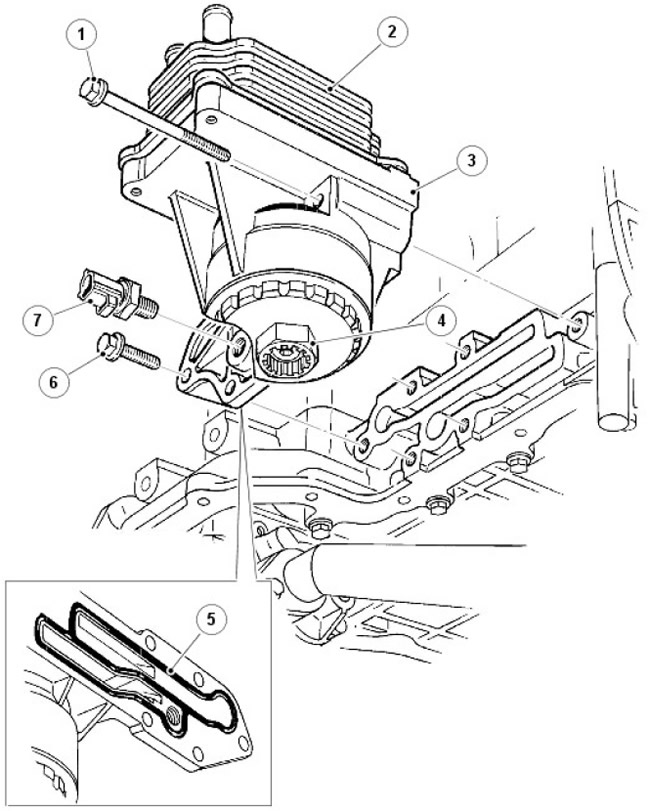

Oil filter and oil cooler assembly

| Pos. | spare part no | Name |

| 1 | - | Bolt (2 pcs.) |

| 2 | - | Oil radiator |

| 3 | - | Oil filter housing |

| 4 | - | Oil filter drain plug |

| 5 | - | Seal for oil filter and oil cooler assembly |

| 6 | - | Bolt (4 things.) |

| 7 | - | Oil pressure sensor |

The engine is lubricated through a pressure lubrication system using an oil filter assembly and an oil cooler.

The oil filter and oil cooler assembly mounts to the left side of the ladder frame and includes a container-type full-flow replacement filter, oil cooler, and oil pressure sensor. The base plate is centered on the oil gallery in the ladder frame and sealed with an O-ring.

The engine cooling system cools the oil in the radiator. Its operation is controlled by a separate thermostat, which prevents coolant from entering through the oil cooler at low engine temperatures, ensuring that the engine warms up quickly. The thermostat opens at 75±2°C.

Oil is fed into and out of the oil cooler through galleries in the cylinder block. Hoses from the engine cooling system, which provide the supply and return of coolant, are connected to two pipes of the oil cooler.

Operation of the lubrication system

From the sump, through a strainer and an oil inlet, oil enters the oil pump, which has a built-in oil safety valve. The strainer and oil pick-up pipe prevent the passage of foreign particles through the oil pump and thus protect it from damage and prevent clogging of the oil passages. The oil relief valve in the oil pump opens when the oil pressure becomes too high and diverts the oil back around the pump.

The lubrication system is designed so that most of the oil flow is directed to the main oil gallery of the cylinder block, and less (determined by a restrictor in the oil filter housing) - to the oil cooler. The rest of the oil flow from the outside of the oil filter is combined with the return flow from the oil cooler and then fed into the main oil gallery of the cylinder block.

The main oil gallery has channels through which oil is supplied to the cylinder head and main bearings. Cross-drilled holes in the crankshaft main bearings supply oil to the connecting rod bearings. Oil galleries in the cylinder head supply oil to the camshafts and hydraulic lash adjusters.

The oil pressure sensor is located in the oil filter and on the oil cooler base plate; it measures the level of oil pressure in front of the main gallery of the cylinder block. When a low oil pressure is detected, the control lamp on the instrument panel turns on.

Slightly pressurized oil enters the cylinder head through the dowel pin stop in the cylinder block/cylinder head. Then the oil enters the camshaft housing through a channel in the cylinder head bore and is fed through separate holes to the camshaft bearings and hydraulic tappet housings. The return oil from the cylinder head drains into the sump through the cylinder head bolt channels.

Comments on this article