Removing

Warnings:

- Some fuel will inevitably spill during this operation. Ensure that all necessary precautions have been taken to prevent fire and explosion.

- Do not carry or use a cell phone while working on or in the vicinity of any fuel related items. There is a danger of ignition of flammable vapours. Failure to follow these instructions may result in injury.

- Do not smoke or walk with a lit cigarette or any type of open flame while working on or near fuel related items. There is a danger of ignition of flammable vapours. Failure to follow these instructions may result in injury.

- If fuel gets in your eyes, rinse them with cold water or special eyewash solution and seek immediate medical attention.

- Wash your hands thoroughly after handling fuel as prolonged skin contact with fuel may cause irritation. Seek medical attention if irritation occurs.

- Do not carry out any repairs to the fuel system while the engine is running. The fuel pressure in the system can reach 2000 bar. Failure to follow this instruction may result in injury.

CAUTION: Diesel fuel injection equipment is manufactured to very precise tolerances and very close clearances. Therefore, when working with these nodes, absolute cleanliness is required. Be sure to install new plugs in all open holes and piping. Failure to follow this instruction may lead to the penetration of dirt into the fuel injection system.

1. Disconnect the wire "masses" from the battery.

For more information, see the chapter: Disconnecting and connecting the battery (414-01 Battery, Battery Mount and Wires, General Procedures).

2. Using a vacuum cleaner, remove foreign material from the high pressure fuel supply lines, fuel manifolds and high pressure fuel pump.

For more information, refer to the chapter: Cleaning the fuel injection system components (303-04A Fuel Supply and Controls - ID4 2.4L Diesel Engine, General Procedures).

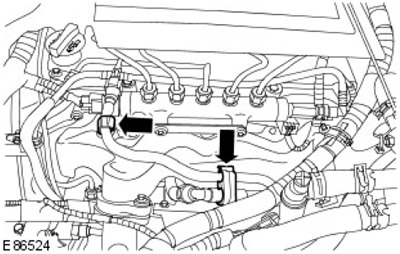

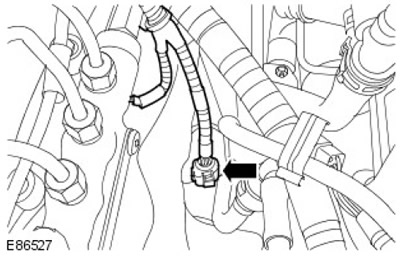

3. Release the fuel line.

4.

CAUTION: Plug all openings. Use new caps.

Disconnect the fuel return line.

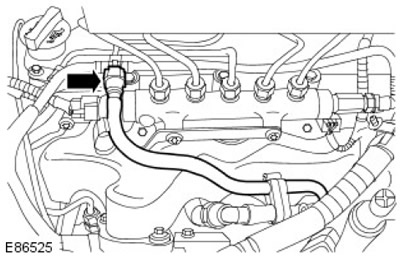

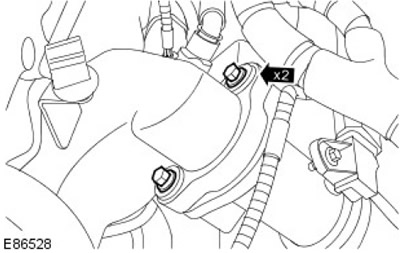

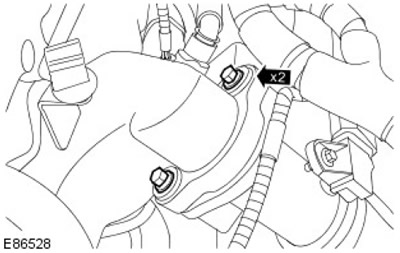

5. Disconnect the camshaft position sensor electrical connector (CMP).

6. Disconnect the wire harness clamp.

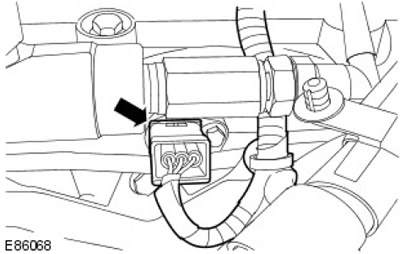

7. Disconnect the EGR valve electrical connector (EGR).

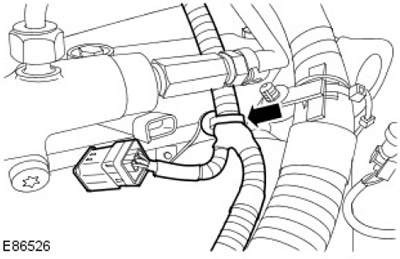

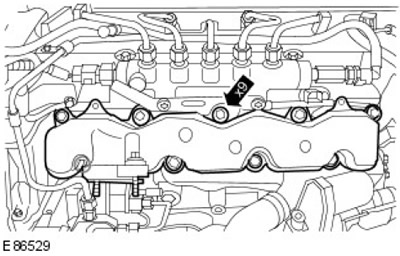

8. Turn out 2 bolts from an inlet collector.

9.

CAUTION: Plug all openings. Use new caps.

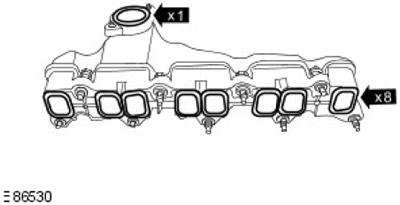

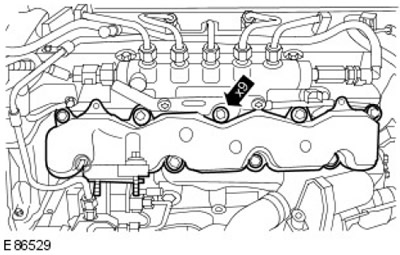

Remove the intake manifold. Remove 9 bolts.

10. Remove and discard 9 intake manifold O-rings.

Installation

1.

NOTE: Clean the contact surfaces of the elements.

Install new intake manifold o-rings.

2.

NOTE: Remove and discard plugs.

Install the intake manifold. Tighten the bolts (tightening torque 15 Nm).

3. Tighten the bolts (tightening torque 10 Nm).

4. Connect the EGR valve electrical connector.

5. Connect the CMP sensor electrical connector. Fasten the wiring harness.

6.

NOTE: Remove and discard plugs. Connect the fuel return line.

7. Connect the fuel line.

8. Connect the wire "masses" to the battery.

For more information, see the chapter: Connecting the Battery (414-01 Battery, Battery Mount and Wires, General Procedures).

Comments on this article