Piping and clutch connections

1. Check hydraulic clutch system piping and connections for friction wear, leaks and corrosion.

Power steering lines and connections

1. Check hydraulic clutch system piping and connections for friction wear, leaks and corrosion.

Engine, gearbox, transfer case and axles

1. Check for oil leaks from the engine, gearbox, transfer case and axles. Pay special attention to the areas around the oil seals.

Exhaust system

1. Visually check the condition of the exhaust system for signs of damage.

2. Check up a condition of heat-shielding screens of system of release.

3. Check up reliability of fastening of system of release and a condition of its rubber support, clips and arms.

Steering housing and suspension

1. Check up elements of fastening of a case of the steering mechanism.

For more information, please refer to the chapter: Specifications (204-00 Suspension - General Information, Specifications).

2. Check up elements of fastening of the left and right forward trailing arms. Tighten if necessary.

For more information, please refer to the chapter: Specifications (204-00 Suspension - General Information, Specifications).

3. Check the fastening elements of the Panhard bar. Tighten if necessary.

For more information, please refer to the chapter: Specifications (204-00 Suspension - General Information, Specifications).

4. Check up all elements of fastening of the back bridge. Tighten if necessary.

For more information, please refer to the chapter: Specifications (205-02 Rear Drive Axle/Differential, Specifications).

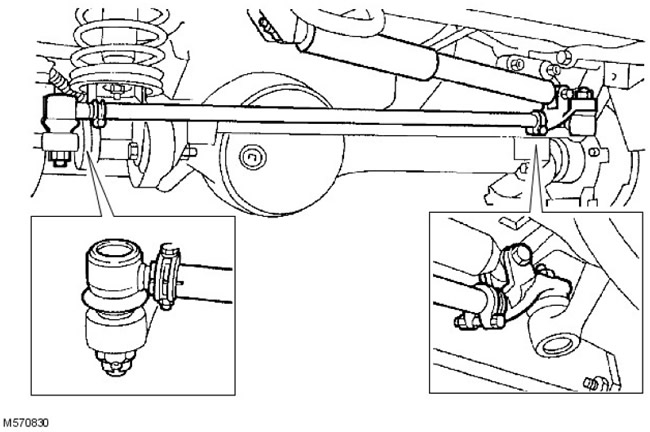

Steering ball joints

1. Check the joints for wear by trying to move the joint from side to side and back and forth. If play is evident, install a new joint.

CAUTION: Do not check for wear by observing the joint while having an assistant turn the steering wheel from side to side.

2. Check up a condition of spherical hinges of a steering, paying special attention to dustproof covers.

NOTE: If it is necessary to replace the steering ball joints, the customer should be consulted as additional labor and/or material costs are required and repairs should not be performed without the customer's consent.

NOTE: Ball joints are lubricated for life and do not require additional lubrication unless the rubber boot has been dislodged or damaged. All joints should be checked at prescribed intervals, or even more frequently if the vehicle is driven under severe conditions.

Shock absorbers

1. Check shock absorbers for signs of leakage.

2. Check shock absorbers for signs of damage.

Towing bracket

1. Check up reliability of fastening of a towing arm.

Engine and gearbox mounts

1. Check up a condition of the left forward support of the engine. Tighten the fasteners if necessary. For more information, please refer to the chapter: Specifications (303-01 Engine - Diesel engine ID4 2.4L, Specifications).

2. Check up a condition of the right forward support of the engine. Tighten the fasteners if necessary. For more information, please refer to the chapter: Specifications (303-01 Engine - Diesel engine ID4 2.4L, Specifications).

3. Check up a condition of the left back support of a transmission. Tighten the fasteners if necessary.

For more information, please refer to the chapter: Specifications (308-03 Manual Transmission / Transaxle Transmission, Specifications).

4. Check up a condition of the right back support of a transmission. Tighten the fasteners if necessary.

For more information, please refer to the chapter: Specifications (308-03 Manual Transmission / Transaxle Transmission, Specifications).

Comments on this article