WARNING: Wheel balancing must always be performed outside the vehicle. Operating the vehicle with unbalanced wheels can result in component damage or personal injury and is therefore NOT PERMITTED.

NOTE: Before attempting to balance the wheel/tire assembly, completely clean any dirt deposits from both the inside and outside of the rim and remove any existing balance weights.

Remove pebbles from the tire tread to avoid injury to the operator when performing dynamic balancing and ensure proper balance.

Inspect tires for damage and correct pressure and balance according to equipment manufacturer's instructions.

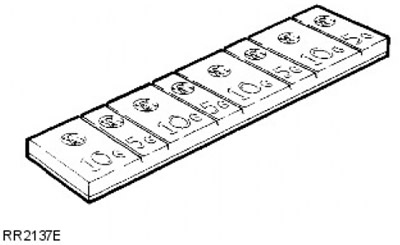

Wheels with steel rims

Clean the wheel rim area and attach the balance weights in the locations shown.

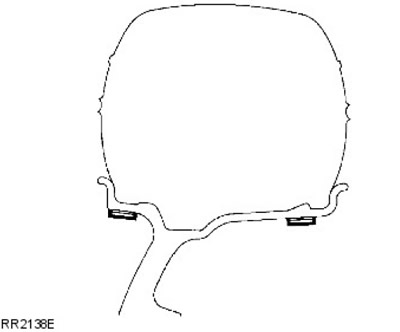

Wheels with alloy wheels

Clean the wheel rim area and attach the adhesive balance weights in the positions shown. Cut through the back of the weight strip to remove the required weights.

CAUTION: Use only the correct adhesive weights to avoid damage to the aluminum wheel rim. DO NOT attempt to use steel wheel weights on an aluminum wheel.

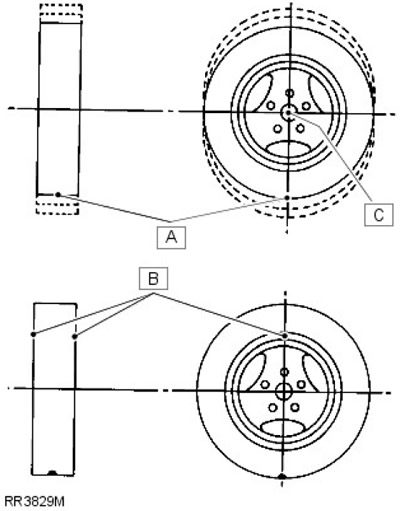

Static balancing

Vibration of wheels in vertical and transverse planes

| Pos. | spare part no | Name |

| A | - | Place of high density. |

| B | - | Add balance weights here |

| C | - | Center line of the axle. |

Static balance is the uniform distribution of mass around the circumference of the wheel. Statically unbalanced wheels cause angular vibration of the wheels. This condition eventually leads to uneven wheel wear.

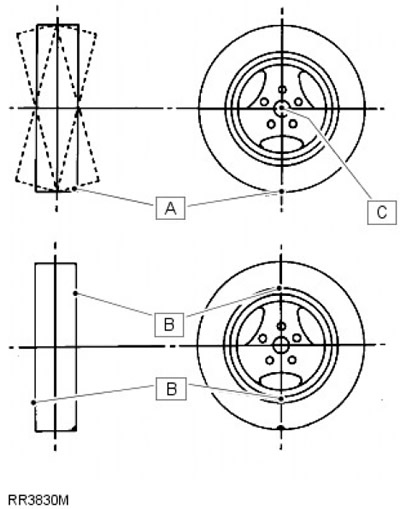

Dynamic balance

Angular oscillatory movement of steered wheels

| Pos. | spare part no | Name |

| A | - | Place of high density. |

| B | - | Add balance weights here |

| C | - | Center line of the axle. |

Dynamic balance is an even distribution of mass on each side of the centerline so that when the wheel is spinning rapidly, there is no tendency for the wheel to move side to side. A dynamically unbalanced wheel causes angular oscillatory motion of the steered wheels.

Vehicle imbalance

Balance the wheels following the equipment manufacturer's instructions.

It is essential that the wheel is mounted using the center hole and NOT the stud holes. To ensure reliable fastening of the wheel, the diameter of the mounting lug on the shaft of the stand must be equal to 112.80 - 112.85 mm. This diameter ensures that the shaft lug fits correctly in the center hole of the wheel.

To secure the wheel on the stand without causing damage to the wheel, always use the car's wheel nuts whenever possible. If this is not possible, the set nuts must be of the same type as the original wheel nuts. The use of conical wheel nuts for this purpose can cause surface damage on alloy wheels.

Cleaning

Wash aluminum wheels using a suitable, properly diluted mastic detergent concentrate and rinse with cold, clean water. DO NOT use abrasives or aluminum wheel cleaners that contain acid, as they will damage the paintwork.

Tire replacement

Use only tire changing equipment to mount or remove tires, following the equipment manufacturer's instructions. DO NOT use hand tools or wheel wrenches as they may damage the tire bead or wheel rim.

Puncture repair

Remove the punctured tire from the wheel and repair it using a universal service plug and a vulcanizing patch. When using a puncture repair kit, be sure to follow the manufacturer's instructions.

Punctures can only be repaired in the tread area. DO NOT attempt to repair punctures in the shoulders or sidewalls of tires.

Do not attempt to repair a tire with the following defects: bulges or bulges, delamination, bead breakage or cracking, wear indicators, and punctures larger than 6 mm in diameter.

CAUTION: Do not use tire sealants that are injected through the valve spool to repair punctured tires. This can lead to wheel corrosion and tire imbalance.

The rim seat of an aluminum wheel should be cleaned with a non-abrasive cleaner that will remove grease and old rubber. Before fitting or removing a tire, the landing area should be generously lubricated with a suitable tire lubricant.

Comments on this article