General procedures

NOTE: This operation must be carried out using an approved front wheel alignment tool. The following describes the use of basic equipment only. No adjustment of the longitudinal angles of the wheels, camber and inclination of the kingpin is not provided.

1. Park the vehicle on a level surface and point the wheels straight ahead.

2. Push the car so that it «swept» back and forth, and as a result, the suspension took a stable position.

3. Set up the equipment according to the manufacturer's instructions and check the wheel alignment as recommended by the equipment supplier.

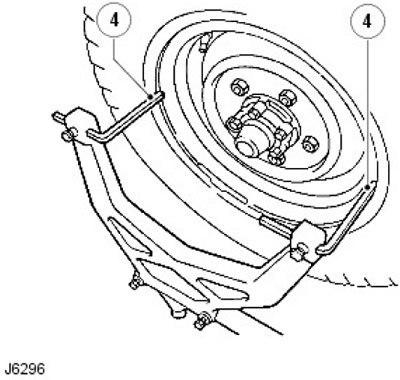

4. Move the feet of the caliper to the inside of the wheels, but not to the rims if the rims are damaged.

5. Measure the toe-in on the horizontal center line of the wheels.

6. Check the tightness of the clamp bolts. Tighten to 14 Nm (10 lb-ft).

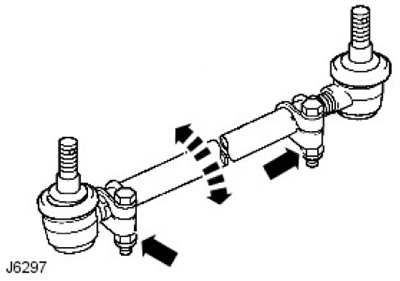

7. Release clips on both ends of steering draft.

8. Rotate the tie rod to increase or decrease its working length until you get the correct toe.

For more information, please refer to the chapter: Specifications (211-00 Steering system - General information, Specifications).

9. Push the vehicle backward by turning the steering wheel from side to side until the ball joints are in a stable position. Bring the front wheels into position «straight ahead» and push the vehicle forward a short distance.

10. Check track and adjust if necessary.

11. Once the wheel alignment is correct, rotate the ball joints in the direction of the arrows to full travel to allow full unrestricted tie rod travel.

12. Tighten the clamping bolts to 14 Nm (10 lb-ft).

Comments on this article