Disassembly

WARNING: Wear safety goggles when removing and installing the lock wheels and retaining ring.

WARNING: When overhauling the steering gear, absolute cleanliness must be observed.

NOTE: The steering gear should not be overhauled during the warranty period. NOTE: This procedure is for Adwest steering only.

1. Remove the steering gear from the vehicle.

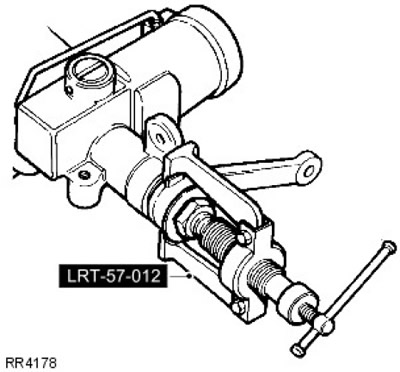

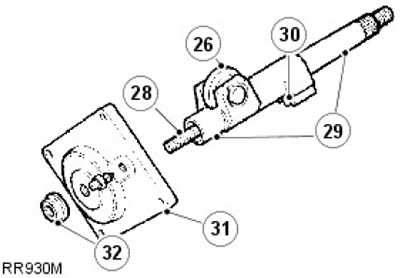

For more information, see chapter: Steering Gear (211-02 Power steering, Removal and installation). Mark the pitman arm and steering gear to facilitate subsequent installation. Remove the steering arm using the LRT-57-012 puller. Loosen the steering arm nut, but do not remove it until the puller is used. Remove the dustproof mechanism from the secondary shaft.

2. Drain oil, remove plugs and bleed screw. Holding the steering gear over a suitable container, rotate the input shaft between the lockout positions to drain the oil. Reinstall the bleed screw.

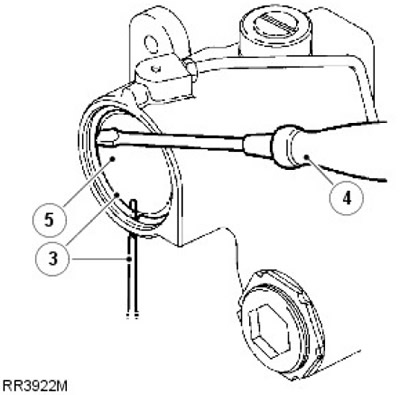

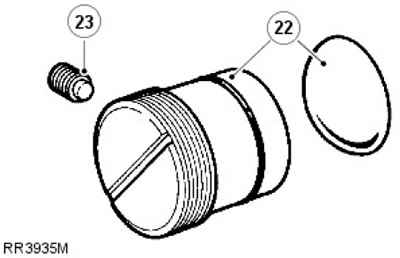

3. Rotate the mounting ring so that one end is 12 mm from the puller hole. Inserting a punch into the hole in the cylinder, lift the circlip out of the groove in the cylinder.

4. Remove the retaining ring with a screwdriver.

5. Rotate input shaft (to the left lock position on left-hand drive vehicles, to the right lock position on right-hand drive vehicles) so that the piston pushes the cover out. Rotate the input shaft fully in the opposite direction while applying pressure to the piston.

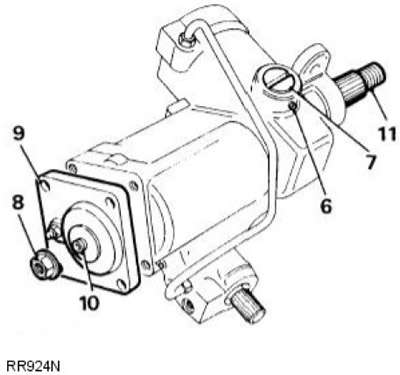

6. Remove the set screw mounting rail spacer adjuster.

7. Remove rack and pinion and gasket.

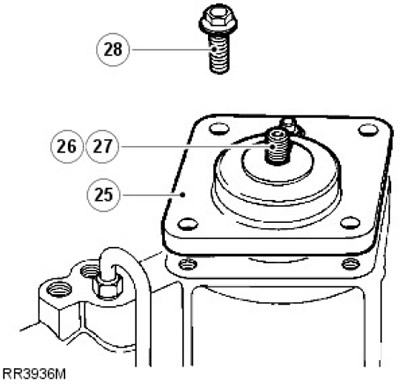

8. Remove the sector shaft adjuster lock nut.

9. Remove the four bolts from the sector shaft cover.

10. Screw in the sector shaft adjuster until the cover is removed.

11. Pull out the sector shaft.

12. Remove the piston; to facilitate the operation, screw a bolt into the piston.

13. Remove the dustproof mechanism of the input shaft.

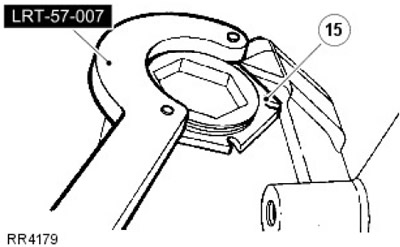

14. Remove the worm adjuster lock nut using a 'C' LRT-57-007 wrench.

15. Remove the worm adjuster using the LRT-57-006 wrench.

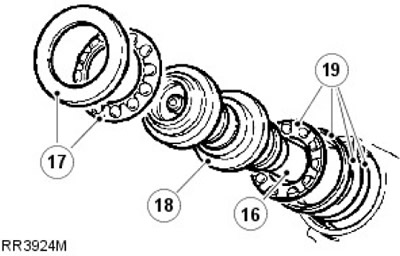

16. Tap the spline end of the shaft to release the bearing.

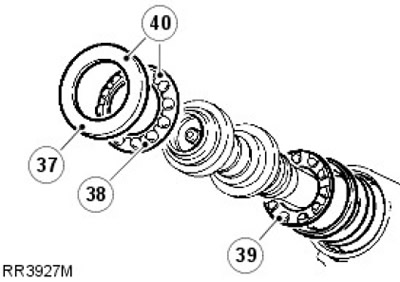

17. Remove bearing outer race and ball bearing assembly.

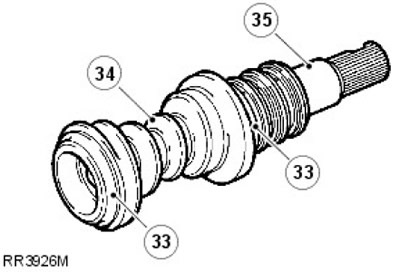

18. Remove valve and worm assembly.

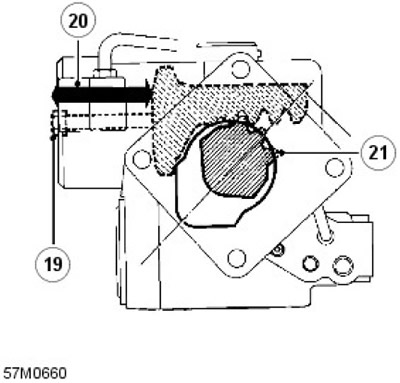

19.

NOTE: If difficulty occurs, heat the cage and bearing assembly. Cool the bearing outer race with a drift and tap the steering gear on a workbench.

Remove bearing inner race, outer race and washers. Save the washers for later assembly.

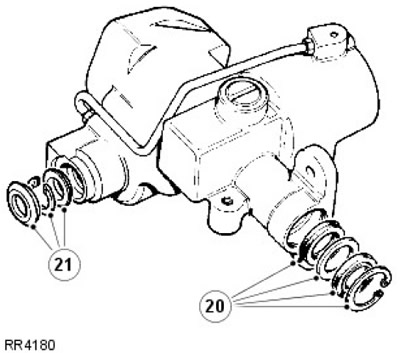

20.

CAUTION: Do not remove the sector shaft bearings from the cage. Spare parts for replacement are not provided. If the sector shaft bearings are worn, install a new steering gear.

Remove the circlip and seal from the sector shaft housing channel.

21.

CAUTION: The use of a seal remover is recommended to avoid the risk of damage to the cage which could result in oil leakage.

Remove the dust guard, circlip and seal from the input shaft housing bore.

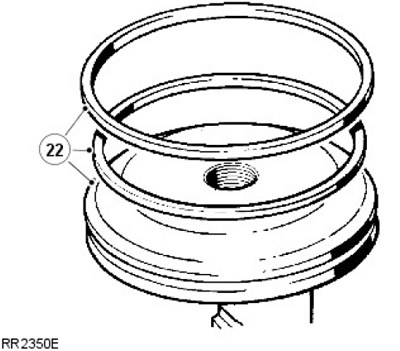

22. Discard all rubber seals, use new seals.

NOTE: The rubber seal is installed behind the plastic ring on the rack piston. Discard the seal and plastic ring.

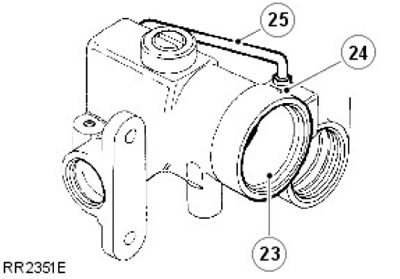

23. Check the piston bore for scratches and signs of wear.

24. Inspect the supply line.

25. If damaged, install a new supply line. Tighten the connection to 22 Nm.

27. If there is side play on the roller, install a new sector shaft.

28. Check the condition of the threads of the adjusting screw. Check the axial play of the regulator. Install a new adjuster if the end play is greater than 0.15 mm.

29. Check for excessive wear on the shaft bearings.

30. Check for uneven or excessive gear tooth wear.

31. Inspect the cover and bearing. Install a new steering gear if damaged or worn.

32. The lock nut also functions as a gland. When assembling, install a new nut.

33. Check for wear on the bearing areas. These areas should be flat, without grooves.

34. Check the condition of the worm guide; it should be flat, without grooves.

35.

NOTE: If any signs of wear are present, a new valve and worm assembly must be installed.

Check for wear on the torsion bar pin assembly. There must be no play between the input shaft and the torsion bar, as well as between the torsion bar and the worm.

40. Repair of bearings and cages is carried out by complete replacement of the element assembly.

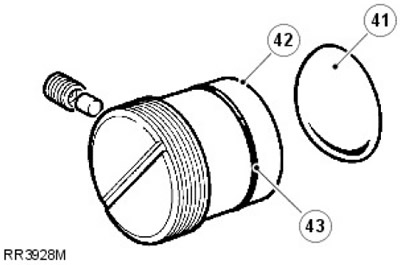

41. Check for scratches on the thrust plate.

42. Check for wear on the plate seat on the regulator.

43. Install a new o-ring to the rack and pinion adjuster.

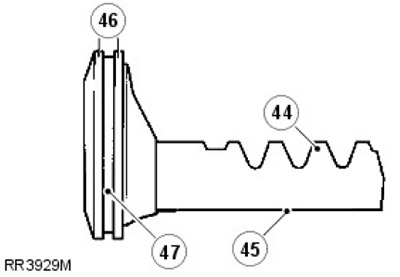

44. Check for excessive wear on the rack teeth.

45. Check that there are no scratches or signs of wear on the bearing surface of the thrust plate.

46. Make sure that there are no burrs or damage on the outer diameters of the piston.

47. Check for scratches and damage on the seal and in the ring groove.

Assembly

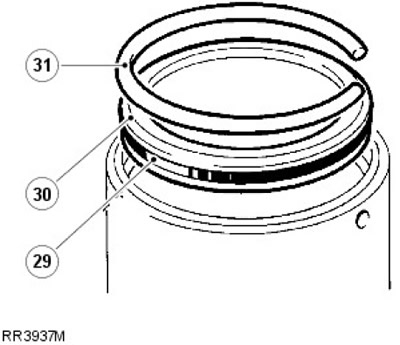

1. Install a new ring on the piston. Heat the nylon seal and install on the piston.

2. Insert the piston assembly into the cylinder; the rail tube must face outward.

NOTE: When installing replacement seals, lubricate them with the recommended working fluid and ensure absolute cleanliness.

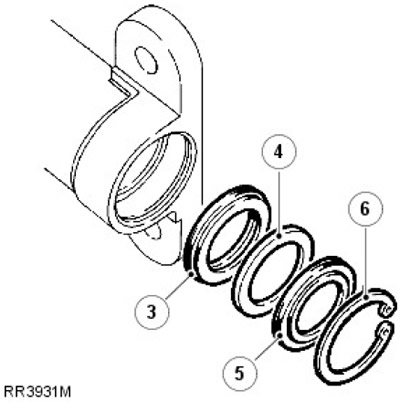

3. Install the gland, starting at the seal side.

4. Install the protective washer.

5. Install the dust seal, finishing at the collar side.

6. Install retaining ring.

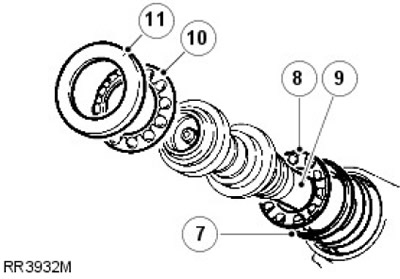

7. Install original washers and bearing inner race. Use Vaseline to make installation easier.

NOTE: If original washers are not used, install washers with a thickness of 0.76 mm.

8. Install inner races and bearing assemblies.

9. Install valve and worm assembly.

10. Install the outer cage and bearing assemblies.

11. Install the bearing outer race.

12. Install a new worm adjuster O-ring.

13. Screw the regulator into the body without tightening.

14. Install but do not tighten the lock nut.

15. Screw in the worm adjuster until the end play is almost completely eliminated. Check the correct seating of the bearing cages.

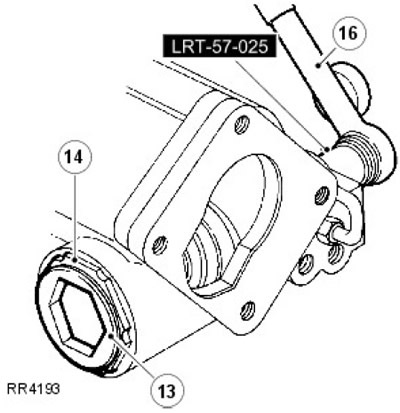

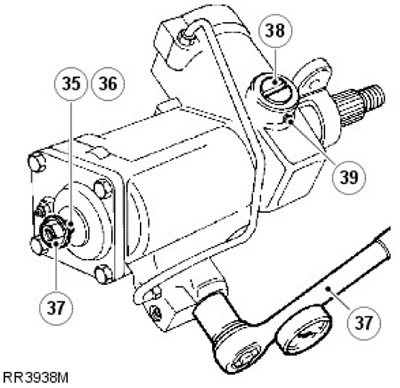

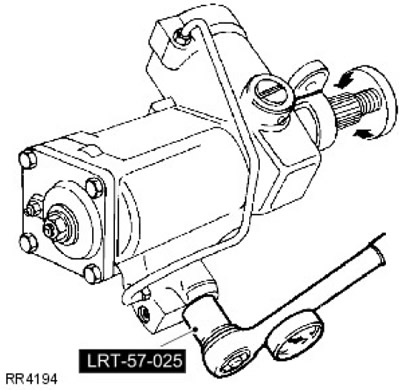

16. Measure the maximum torque of the valve and worm assembly using a torque wrench and slotted chuck LRT-57-025.

17. Screw in the worm adjuster while turning the shaft to increase the measured value to 0.56 Nm.

18. Loosen the worm adjuster by / turn. Screw in the worm adjuster to increase the measured value by 0.21-0.34 Nm, with the lock nut tightened - 100 Nm. Use LRT-57-006 worm adjustment wrench and LRT-57-028 locknut wrench.

19. Screw an auxiliary bolt into the piston to facilitate assembly.

20. Install the piston and rack so that the piston protrudes 70 mm from the outer end of the cylinder.

21. Install the sector shaft using a tool to prevent damage to the seals (LRT-57-021). Align the position of the roller with respect to the recess on the body as shown in the figure. Push the sector shaft inward while rotating the input shaft so that the sector roller engages the worm.

22. Install the rack adjuster and thrust plate to engage the rack. Loosen the regulator half a turn.

23. Loosely install new nylon gasket and regulator set screw assembly.

24. Install a new o-ring on the cover.

25. Align the cover with the body.

26. Screw the cover assembly completely onto the sector shaft adjuster screw.

27. If necessary, remove the sector shaft adjuster screw. Tap the installed cover to ensure it is fully connected to the body.

NOTE: Before tightening the fasteners, turn the input shaft to check for free movement of the sector shaft roller in the valve worm. If initial resistance is felt, turn the adjuster screw about two turns clockwise.

28. Install the cover bolts. Tighten to 75 Nm.

29. Install a new square seal on the cover.

30. Turn out an auxiliary bolt from the piston. Press the cover into the cylinder so that the groove of the retaining ring is exposed.

31. Insert the circlip into the groove so that one end of the circlip is 12mm from the puller hole.

32. Install the pitman arm and tighten it partially to ensure there is no play between the pitman arm and sector shaft.

33. To install the worm in the center position, turn the input shaft to the innermost lock position (to the right lock position on left-hand drive vehicles, to the left lock position on right-hand drive vehicles). Rotate the input shaft back toward the center two full turns.

34. The block is now centered and adjustments can be made.

35. While holding the input shaft, shake the steering arm to check for play. Continue rocking and slowly turn the sector shaft adjusting screw clockwise. Continue turning the adjusting screw until the gap is almost completely eliminated.

36. Install and tighten the lock nut.

NOTE: It is important to center the steering gear before making any adjustments.

37. Check for maximum torque at one and a quarter turn to each side from the center position using a torque wrench and slotted chuck LRT-57-025. Turn the adjuster screw to obtain a torque at the center of 0.34 Nm plus torque at one and a quarter turns. Tighten the regulator locknut to 60 Nm (44 lbf/ft).

38. Turn the rack and pinion to increase the value measured in the previous step by 0.23-0.24 Nm. The final value may be less, but must not exceed 1.35 Nm.

39. Secure the rack and pinion with the set screw. Tighten to 5 Nm.

- 1. When turning the input shaft between the extreme positions of the lock, the torque values \u200b\u200bshould be maximum in the center position and evenly distributed relative to the center position.

- 2. This depends on the thickness of the washers installed between the bearing inner race and the cage on the valve and worm assembly. Unless large parts have been replaced, the original washer thickness provides the correct maximum torque position.

40. Turn the input shaft counterclockwise as far as it will go (the input shaft must face the mechanic).

41. Check the torque values between the extreme lock positions using a torque wrench and spline chuck LRT-57-025.

42. In addition, check for even engagement on both sides about the center.

43. Note where the largest values are recorded relative to the steering position. If the largest values are not registered at the center of the stroke (straight steering), make the following adjustment:

- 1. If the torque peak occurs before the center position, increase the thickness of the washers.

- 2. If the torque peak occurs after the center position, reduce the thickness of the washers.

- 3. Washers are available in the following thicknesses: 0.03mm, 0.07mm, 0.12mm and 0.24mm.

CAUTION: When installing new washers on the valve and worm, be extremely careful not to damage the seals during assembly.

NOTE: Changing the washer thickness by 0.07mm moves the peak torque zone by 1/4.

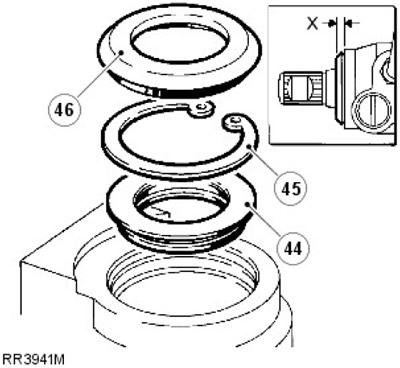

44. Insert the seal, starting at the collar side, into the housing. Use a tool that will not damage the seals (LRT-57-016), and seal installation tool (LRT-57-026). Check the installation of the seal to a depth of 4.75-5.00 mm relative to the front surface of the block.

45. Secure the seal with the circlip.

46. Lubricate the inner boot of the dust guard with PTFE grease. Install the dust protection mechanism using the LRT-57-027 tool. If the installation is correct, the outer protrusion of the dustproof mechanism recedes 4.00-4.50 mm from the front surface of the unit (X size).

47. Remove the steering arm. Lubricate the inner boot of the dust guard with PTFE grease and install so that the outer boot is flush with the housing.

48. With the input shaft centered, align the alignment marks on the steering arm and steering gear. Install the pitman arm to the steering gear using a new lock washer. Tighten to 176 Nm.

49. Install the steering gear.

For more information, see chapter: Steering Gear (211-02 Power steering, Removal and installation).

Comments on this article