Disassembly

1. Disconnect the accumulator and remove the main cylinder from the amplifier.

For more information, see the chapter: Disconnecting and connecting the battery (414-01 Battery, Battery Mount and Wires, General Procedures).

2. Before starting a major overhaul, thoroughly clean the master cylinder and inspect the outer surfaces for damage and check the general condition. Replace the entire assembly if necessary.

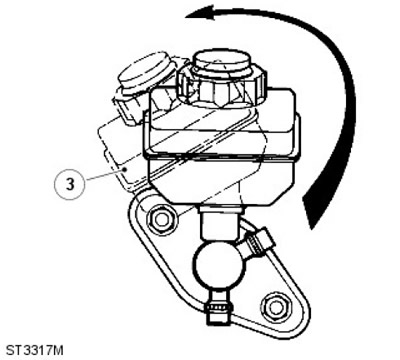

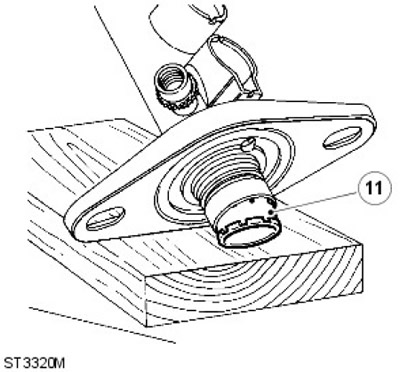

3. The reservoir is fitted with a snug fit on the master cylinder and secured with seals. Carefully remove the reservoir from the master cylinder, «unscrewing» it from the seals, as shown in the figure.

4. Clamp one side of the master cylinder flange in a soft-jawed vise. Remove the O-ring from the flange between the master cylinder and the booster and discard it.

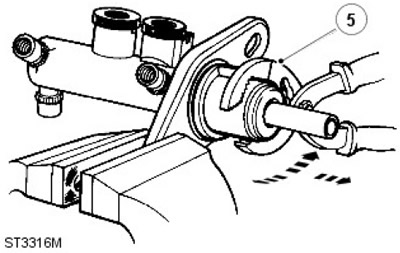

5. Grasp the outside of the coupling housing with a suitable pliers and gently pull the housing out while rocking back and forth with the pliers to disengage the housing from the master cylinder. Discard the housing and vacuum seal.

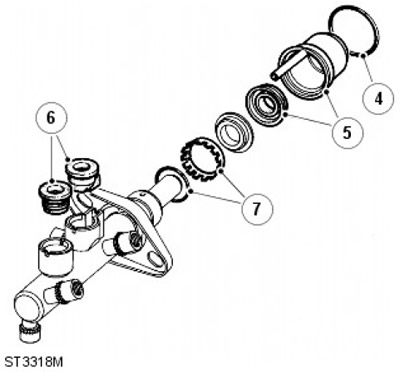

6. Remove the two reservoir seals from the master cylinder and mark their position in the intake ports for reassembly. Discard both seals.

7. Remove the retaining ring and o-ring from the machined outer surface of the master cylinder. Discard the seal and retaining ring.

8. Remove the guide ring from the master cylinder port that supports the primary ram assembly and slide out of the way. This item is not included in the Master Cylinder Service Kit and must be returned to the site when reassembling the block.

9. Remove the primary plunger assembly from the master cylinder.

NOTE: The primary plunger assembly cannot be further disassembled and is serviced as a single unit. Discard the node.

10. The secondary plunger assembly will remain in the bottom of the master cylinder bore. The plunger can be easily removed by tapping the cylinder with a wooden board until the plunger is in the cylinder port. Then carefully remove the plunger from the master cylinder.

11. If the vortex tube was not removed at the same time as the secondary plunger, repeat the above steps to remove it from the bottom of the master cylinder bore. Then discard it.

12. Clean all components with Gilling cleaning fluid or fresh brake fluid. Place the cleaned items on a clean sheet of paper. Inspect the cylinder bore and plungers for signs of corrosion, wear ridges, and scratches. If the work surfaces are in excellent condition, new seals from the Gilling service repair kit can be used.

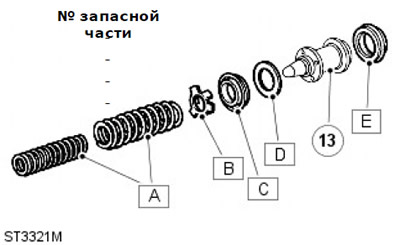

13. Remove the above items from the secondary plunger and discard them:

| Pos. | Name |

| A | Springs |

| B | Seal stop |

| C | Front cuff |

| D | washer |

| E | L-shaped seal |

NOTE: A small rounded and polished screwdriver is required to remove the L-seal. DO NOT damage the secondary plunger.

14. Moisten new seals with fresh brake fluid and first install the L-shaped seal on the plunger.

15. Install the washer, and behind it the front cuff. Install the seal retainer and springs, making sure the springs are properly installed.

CAUTION: Be sure to follow the instructions exactly. Otherwise, when installing the plungers in the cylinder bore, new seals may also be damaged. Lubricate the components liberally with new brake fluid before reassembly.

NOTE: Be careful not to get any dirt into the channels and openings. If dirt is found, carefully remove it, clean the cylinder again and recheck.

1. Install a new swirl tube in the bottom of the cylinder bore.

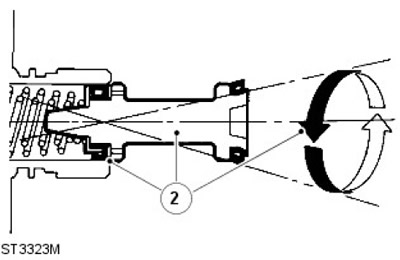

2. Lubricate the secondary plunger and cylinder bore. Insert the plug assembly into the cylinder until the seal is centered against the port flare. Gently insert the plunger with a twisting motion as shown in the figure. Ensure that the seal does not get stuck, insert the seal into the channel and slowly press the plunger into the channel in one continuous motion.

3. Install the primary plug assembly using the same method as for the secondary plug. Push the plunger into the channel.

4. Install the original guide ring to support the primary plug.

5. Coat the new O-ring with brake fluid and insert it into the appropriate groove on the outer mounting surface of the master cylinder.

CAUTION: The o-ring should not twist on the outer mounting surface of the master cylinder, it should be slightly stretched and lowered into the cylinder and into its groove. Do not stretch the seal too much.

6. Install a new mounting ring on the outer surface of the master cylinder, making sure that the small teeth of the ring are facing the mounting flange.

7. Insert two new reservoir seals into the appropriate ports.

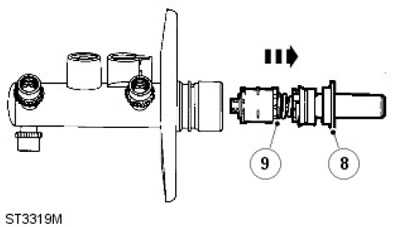

8. Install a new vacuum seal on the primary plug or in the bottom of the connection body bore, with the open side of the seal toward the primary plug guide ring.

9. Lubricate the vacuum seal with brake fluid, install the coupling housing onto the master cylinder, press the housing fully up to the cylinder mounting flange. Do not adjust the connection housing after installation.

10. Lubricate the new water seal with brake fluid, stretch the seal slightly and slide it down into the body until the seal is in the correct position between the body and flange.

11. Place reservoir on top of master cylinder, working in reverse order of step 3.

12. Establish the main cylinder on the amplifier.

For more information, see chapter: Brake Master Cylinder (206-06 Hydraulic brake, Removal and installation).

13. Reconnect the battery and road test the vehicle.

Comments on this article