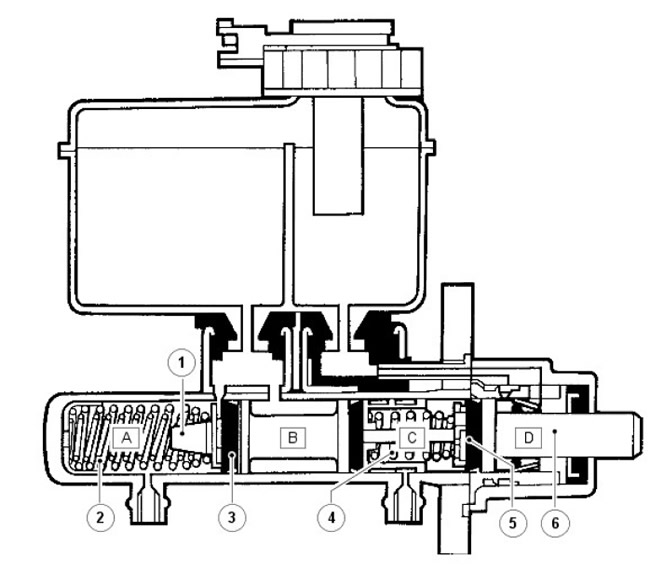

Description of master cylinder

The mechanical elements of the hydraulic brake system consist of brake discs with four-piston calipers at the front and brake discs with two-piston calipers at the rear.

Front ventilated brake discs are standard on 110/130 models, while 90 models have non-ventilated discs. However, ventilated front discs can also be fitted to the 90 with a heavy-duty undercarriage.

The cable operated parking brake operates a single drum brake mounted on the output shaft of the transfer case and is completely independent of the main braking system.

The main hydraulic system includes 2 separate and independent circuits - primary and secondary, which allow you to adjust the degree of braking in the event of a malfunction on one of the circuits. The primary circuit controls the rear brake calipers and the secondary circuit controls the front brake calipers.

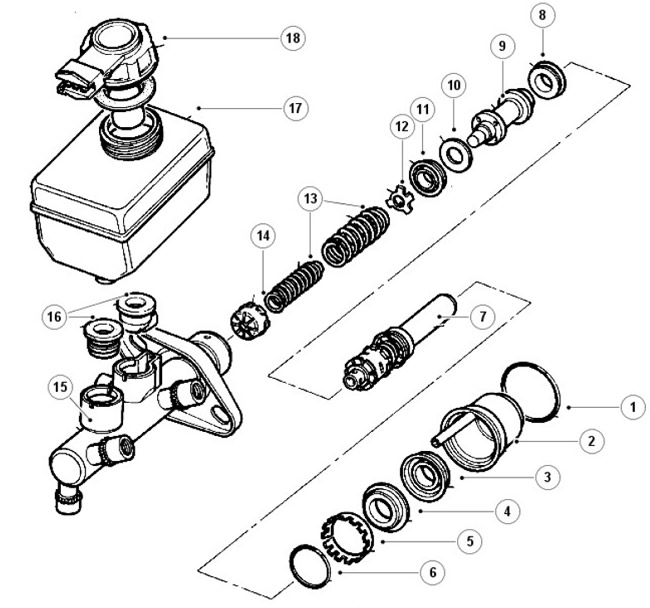

Master cylinder elements

| Pos. | spare part no | Name |

| 1 | - | Auxiliary piston |

| 2 | - | secondary spring |

| 3 | - | Primary cuff |

| 4 | - | Primary spring |

| 5 | - | Primary cuff |

| 6 | - | Main piston |

Master cylinder operation

The tandem-type master cylinder, assisted by a light, short and compact servo cylinder, is powered by a separate feed tank. The rear section supplies brake fluid to the primary circuit, and the front section to the secondary circuit.

If the brakes are not applied, the brake fluid can freely move through the dual-circuit system and between the separate containers of the brake fluid supply reservoir.

When the brake pedal is depressed, the primary piston rises in the cylinder, the resulting pressure, combined with the primary spring, overcomes the force of the secondary spring, thus raising the secondary piston in the cylinder. At the same time, the initial movement of both pistons shifts the primary seal in such a way that it closes the cut-off holes in the cylinder chambers "A" And "WITH", see J6321; the brake fluid in these chambers is pressurized and directed to the appropriate circuits.

The movement of the pistons does not affect the brake fluid in the chambers "IN" And "D"; the liquid can freely move between the individual chambers and the corresponding containers of the supply tank, both before pressing the brake pedal and after using the brakes. When the brakes are released, the pistons are moved back faster by the return springs than the brake fluid; this creates a pressure difference between the brake fluid in the chambers "A" And "WITH" and primary cuffs.

The primary seals retract instantly, allowing the brake fluid in the chambers to "IN" And "D" flow through the holes in the pistons, through the tightened cuffs into the chambers "A" And "WITH" respectively. The movement of brake fluid from one group of chambers to another is compensated by brake fluid from separate containers in the supply tank, which passes through the supply holes in the cylinder. The final return movement of the pistons causes the excess brake fluid in the chambers to "A" And "WITH" flow through the cut-off holes into the brake fluid supply reservoir.

The servo unit facilitates the depressing of the brake pedal by providing an auxiliary force. Auxiliary force is provided by a vacuum pump located on the right side of the cylinder block. A vacuum is created on both sides of the flexible diaphragm; atmospheric pressure acts on the rear diaphragm, thereby achieving an auxiliary force. The servo unit is installed between the brake pedal and the master cylinder and is connected to them by push rods. If a vacuum break occurs, the two push rods act as a single unit, thereby ensuring the normal functioning of the brakes. But in this case, more effort is required to work with the brake pedal.

Repair elements of the master cylinder

| Pos. | spare part no | Name |

| 1 | - | A seal that protects against water penetration |

| 2 | - | transmission housing |

| 3 | - | Vacuum sealer |

| 4 | - | guide ring |

| 5 | - | Retaining ring |

| 6 | - | O-ring of circular cross-section |

| 7 | - | Main piston assembly |

| 8 | - | L-shaped seal |

| 9 | - | Auxiliary piston |

| 10 | - | Washer |

| 11 | - | Primary cuff |

| 12 | - | Seal housing |

| 13 | - | Springs |

| 14 | - | spiral pipeline |

| 15 | - | master cylinder housing |

| 16 | - | Tank seals |

| 17 | - | Tank |

| 18 | - | Low Brake Fluid Level Switch and Cap |

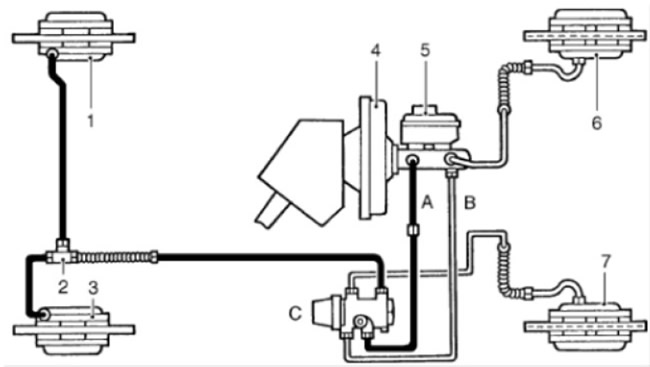

Hydraulic system

At recommended service intervals, drain the brake fluid and flush the brake system.

The brake fluid loss sensor is installed on the filler cap of the master cylinder reservoir. The sensor is connected to the control lamp circuit on the car's instrument panel; The lamp comes on when checking the indicator lamps, when the ignition is turned on, and goes out when the engine is started and the parking brake is released. A hydraulic failure in the system will cause a loss of brake fluid, causing the warning light to come on.

On models 90 pressure reducing valve (PRV), mounted on the right bulkhead in the engine compartment, maintains brake balance, see J6322. The pressure supplied to the rear brake calipers is controlled by a pressure reducing valve. This valve is a kind of emergency relief valve; in the event of a malfunction of the front (secondary) brake circuit, it directs all the pressure in the system to the rear brake calipers.

Models 90

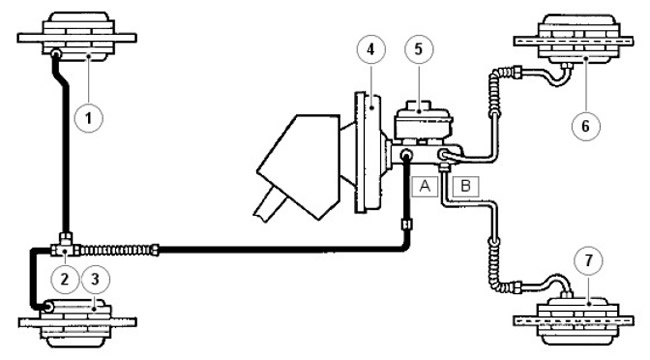

Models 110/130

NOTE: In some countries, to comply with legal requirements, a relief valve may be installed on the Model 110.

| Pos. | spare part no | Name |

| A | - | Main circuit |

| B | - | secondary circuit |

| C | - | pressure reducing valve |

| 1 | - | Left rear brake caliper |

| 2 | - | Tee |

| 3 | - | Right rear brake caliper |

| 4 | - | Brake servo cylinder |

| 5 | - | Master cylinder and tank |

| 6 | - | Left front brake caliper |

| 7 | - | Right front brake caliper |

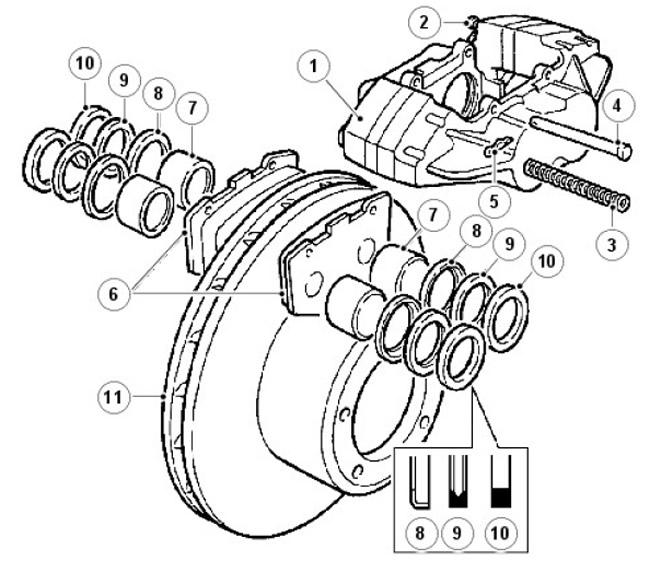

Front brake caliper assy

Elements of the front brake caliper

| Pos. | spare part no | Name |

| 1 | - | caliper |

| 2 | - | Air release screw |

| 3 | - | De-rattling springs |

| 4 | - | Shoe fastening pins |

| 5 | - | cotter pin |

| 6 | - | friction linings |

| 7 | - | Piston |

| 8 | - | Wiper sleeve retainer |

| 9 | - | Wiper cuff |

| 10 | - | hydraulic seal |

| 11 | - | Brake disk |

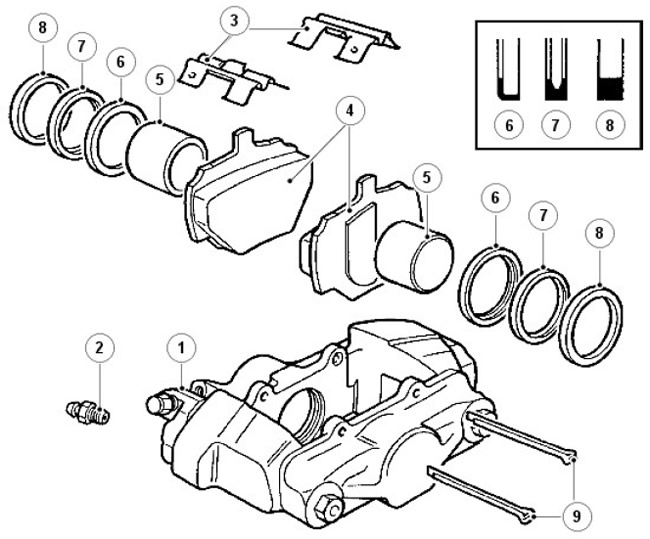

Rear brake caliper assy

Elements of the rear brake caliper

| Pos. | spare part no | Name |

| 1 | - | caliper |

| 2 | - | Air release screw |

| 3 | - | Pad retaining springs |

| 4 | - | brake pads |

| 5 | - | Piston |

| 6 | - | Wiper sleeve retainer |

| 7 | - | Wiper cuff |

| 8 | - | hydraulic seal |

| 9 | - | Mounting pins |

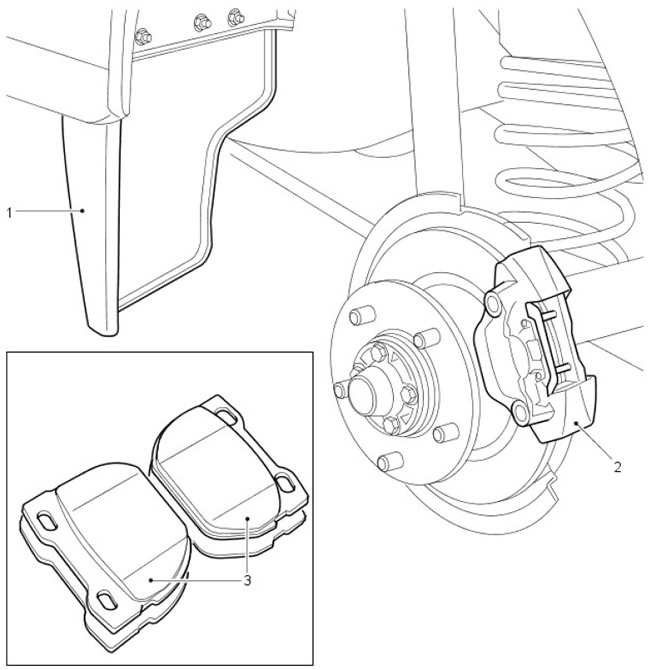

Installing the rear brake caliper - from model year 2002

| Pos. | spare part no | Name |

| 1 | - | Deflector |

| 2 | - | Rear brake caliper |

| 3 | - | rear brake pads |

Rear brake modifications were introduced on the 110 and 130 models. This is to increase the life of the rear brake pads in harsh outdoor conditions.

New rear brake calipers are introduced to allow the use of brake pads with a thicker layer of friction material. Brake pads have increased leading and trailing edge chamfers to increase efficiency.

Aerodynamic deflectors are located in front of the rear wheels to protect the rear calipers from dirt ingress that can cause excessive pad wear. Deflectors are fitted to models 90, 110 and 130 sold in countries whose environmental conditions may cause excessive brake pad wear.

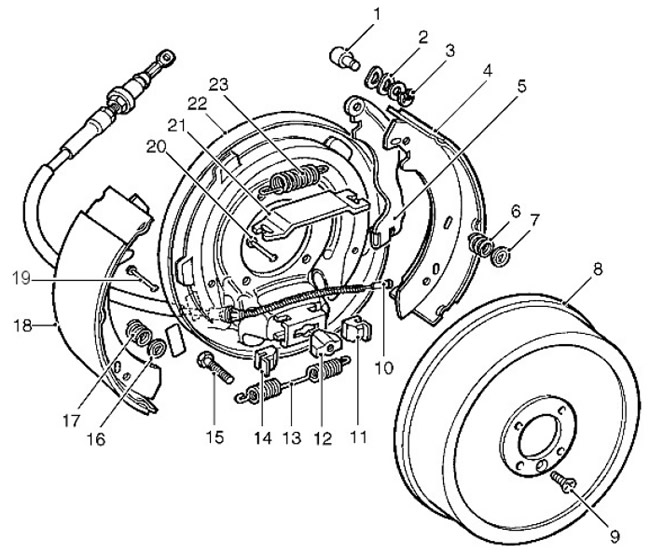

Parking brake

Parking brake elements

| Pos. | spare part no | Name |

| 1 | - | Pin |

| 2 | - | Washer |

| 3 | - | C-clamp |

| 4 | - | Brake shoe |

| 5 | - | Rope lever |

| 6 | - | retaining spring |

| 7 | - | Belleville washer |

| 8 | - | brake drum |

| 9 | - | Screw |

| 10 | - | Brake cable |

| 11 | - | Regulator slider |

| 12 | - | Regulator nut |

| 13 | - | Spring |

| 14 | - | Regulator slider |

| 15 | - | Adjusting bolt |

| 16 | - | Belleville washer |

| 17 | - | retaining spring |

| 18 | - | Brake shoe |

| 19 | - | Support leg |

| 20 | - | Support leg |

| 21 | - | Base plate |

| 22 | - | Brake Shield |

| 23 | - | Spring |

Comments on this article